Surface mine mining dust removal system

A dust removal system and mine technology, applied in dust prevention, mining equipment, earth drilling and mining, etc., can solve the problems of slowing down mining efficiency, affecting the clarity of vision inside the mountain, affecting the health of workers, etc., to increase the dust removal area, The effect of improving mining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

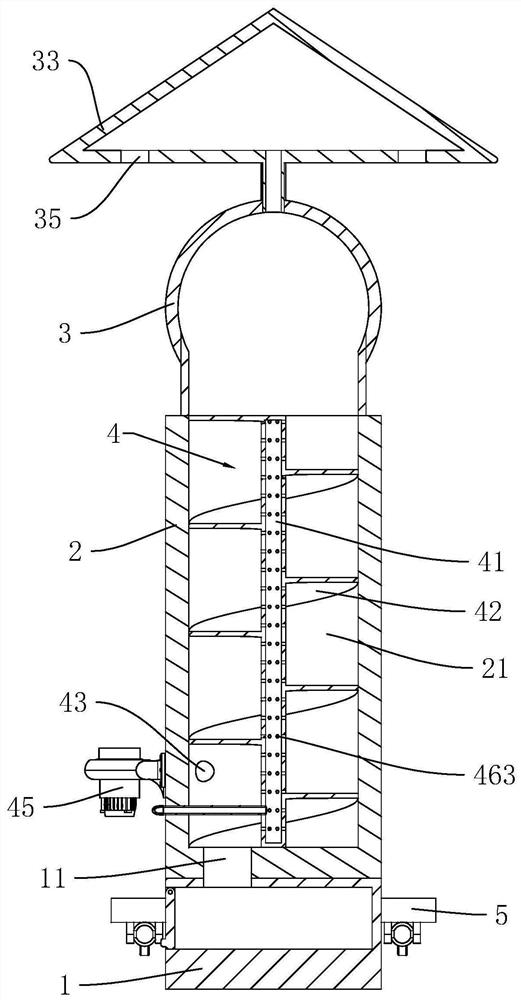

[0035] The following is attached Figure 1-7 The application is described in further detail.

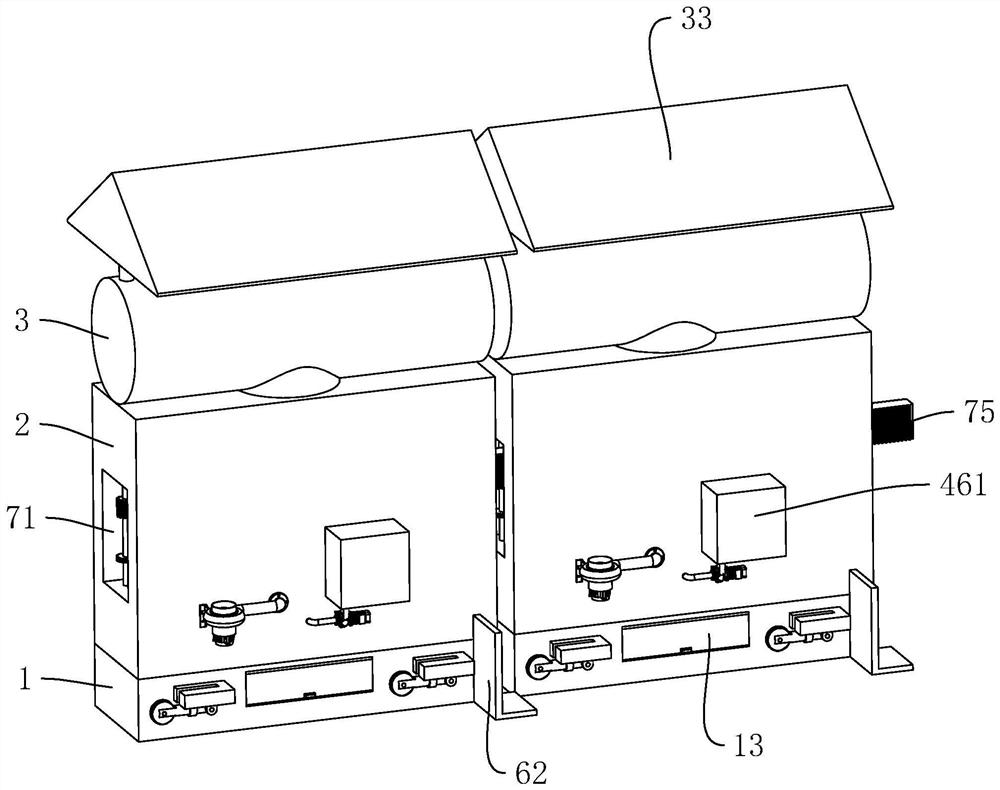

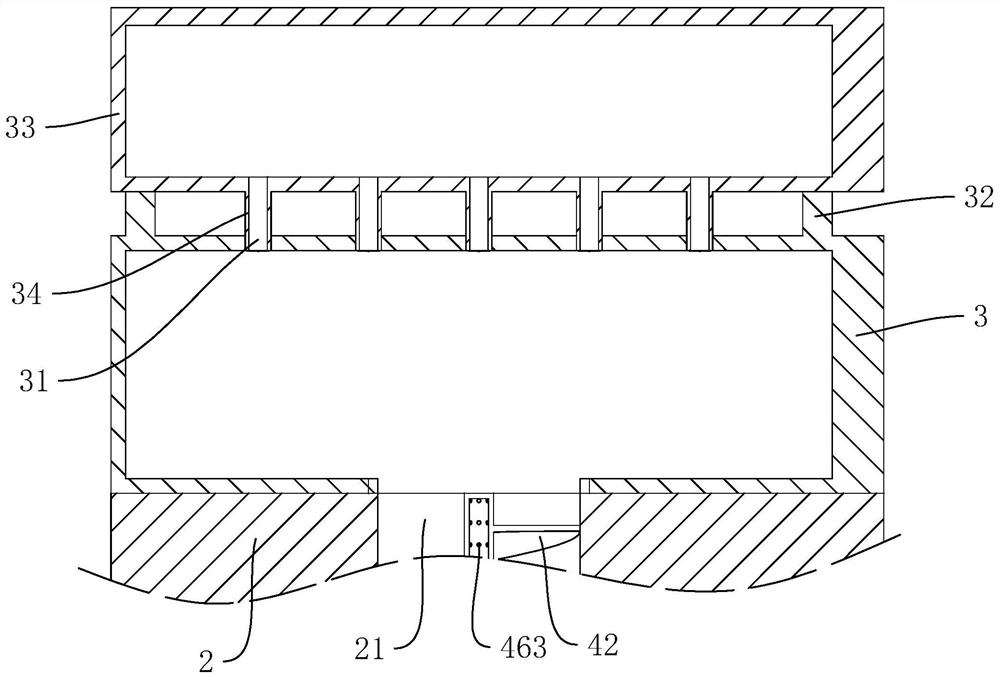

[0036]The embodiment of the present application discloses a dust removal system for open-pit mining. refer to figure 1 and figure 2 , a dust removal system for open-pit mining includes a horizontal base 1, the base 1 is arranged in a strip shape, and the upper surface of the base 1 is welded with a vertical support plate 2, the support plate 2 is arranged in a rectangular shape, and supports The length direction of the plate 2 is arranged horizontally. The upper end of the support plate 2 is welded with a horizontal pipe 3, the pipe 3 is arranged in a hollow cylindrical shape, and the pipe 3 is arranged along the length direction of the support plate 2, and the upper end of the pipe 3 is provided with a plurality of flow holes 31, and the several flow holes 31 are arranged along the length of the pipe 3. Orientation isometric arrangement set.

[0037] refer to figure 2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com