Combined oil seal structure

A combined oil seal technology, which is applied to engine seals, engine components, mechanical equipment, etc., can solve the leakage of skeleton oil seal and shaft seal, the pressure force between oil seal body and shaft becomes smaller, and the elastic force of spring tends to become smaller, etc. problem, to achieve the effect of increased sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

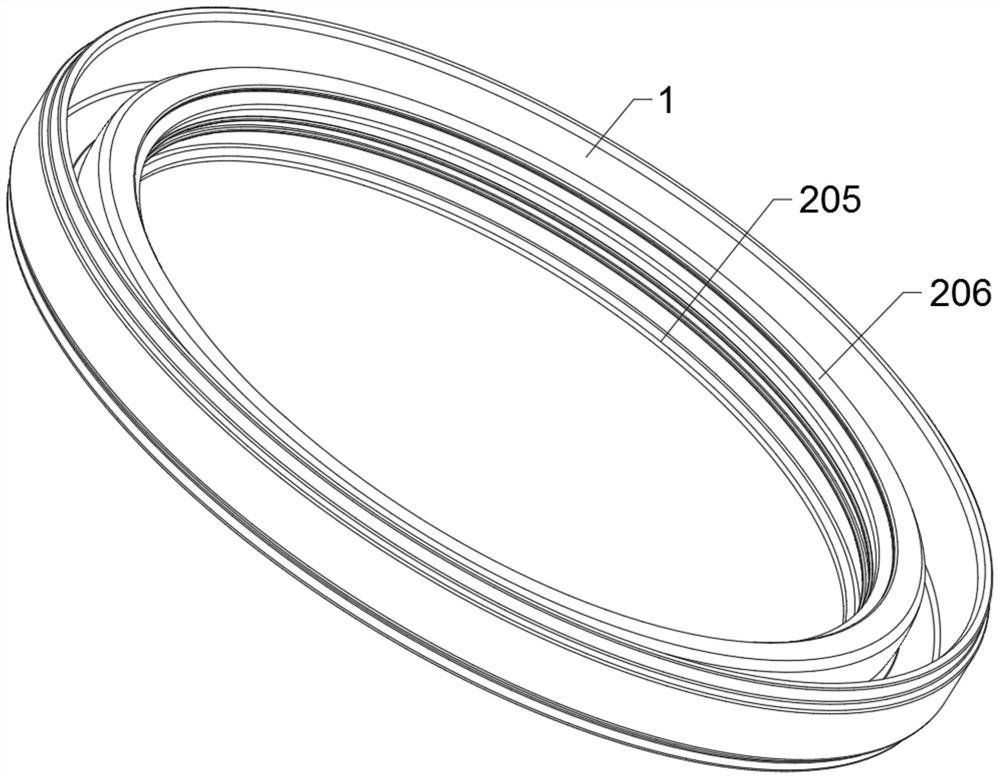

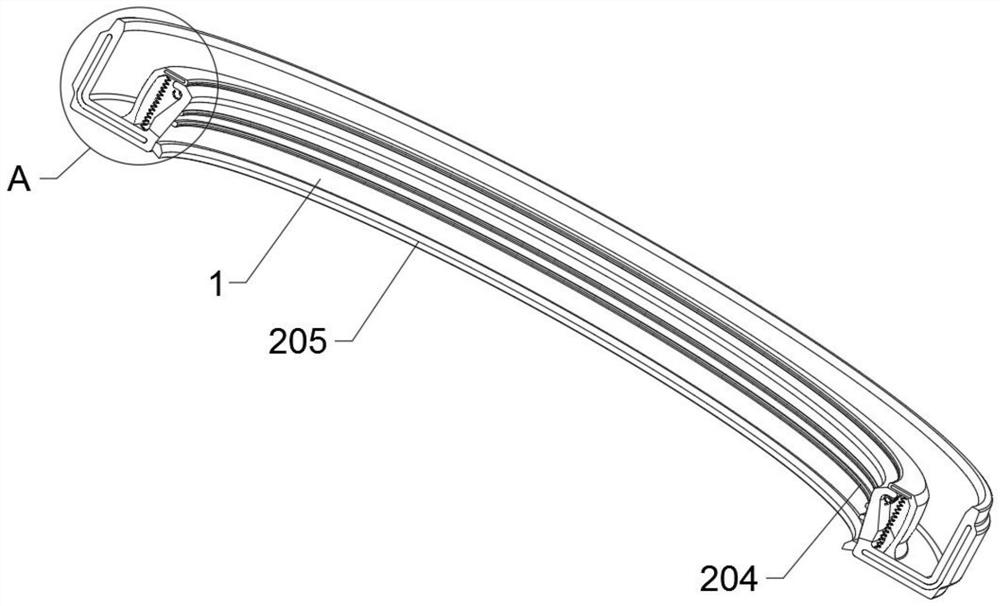

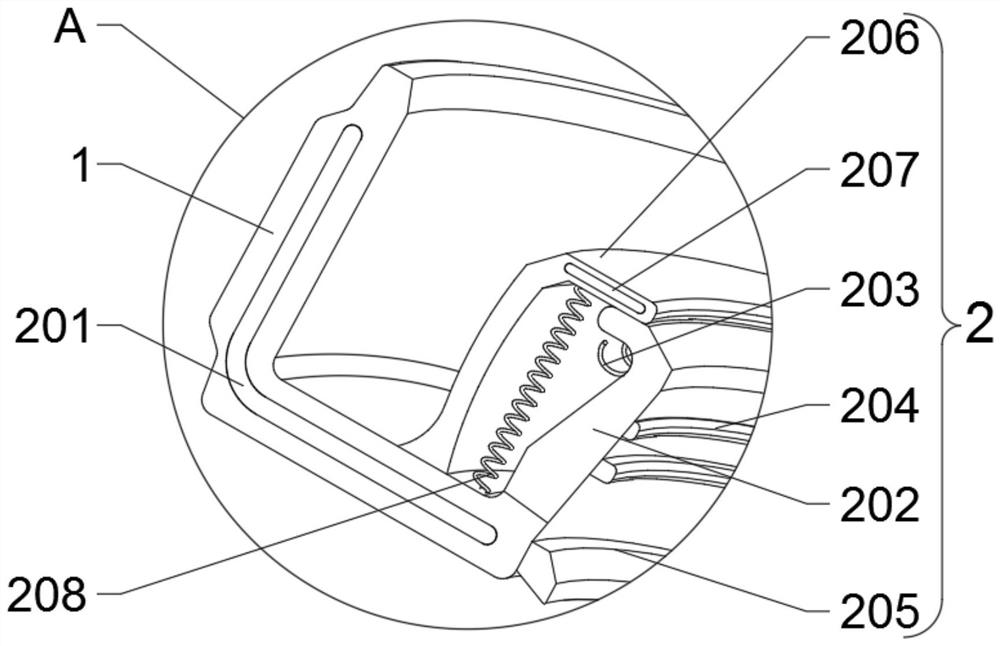

[0020] Example 1, such as Figure 1-3 As shown, the present invention provides a combined oil seal structure, which includes a rubber body 1 , and a sealing mechanism 2 is arranged inside the rubber body 1 .

[0021] Let's talk about the concrete setting and effect of its sealing mechanism 2 in detail.

[0022] Such as Figure 1-3 As shown, the sealing mechanism 2 includes a supporting frame 201, the inside of the rubber body 1 is a cavity structure, the bottom of the supporting frame 201 is adhered to the inner surface wall of one side of the rubber body 1, and the inner bottom surface of the rubber body 1 is adhered with a sealing rubber 202, the outer surface of the sealing rubber 202 is provided with an annular groove, and the inside of the annular groove is provided with a spring ring 203, and the inner bottom surface of the rubber body 1 close to the side of the sealing rubber 202 is adhered with a protective rubber 206, and the protective rubber 206 The bottom is adhe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com