An angle sensor installation tool

An angle sensor and installation tooling technology, applied in the field of measurement and control, can solve problems such as inaccurate detection data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

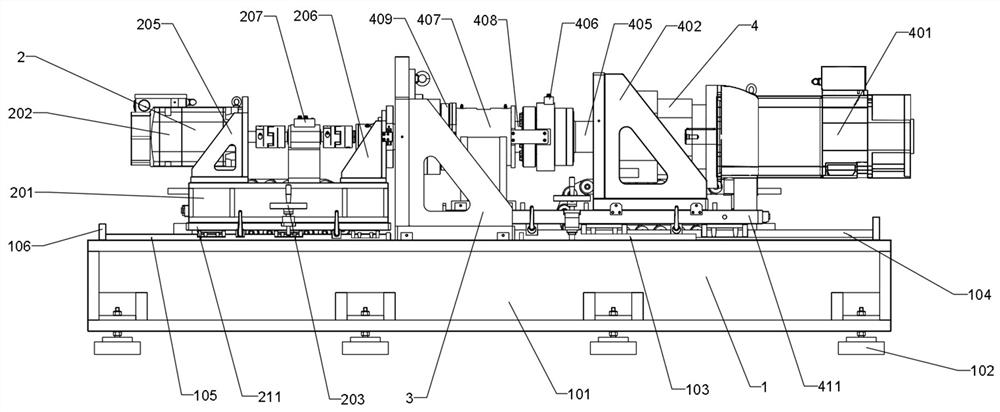

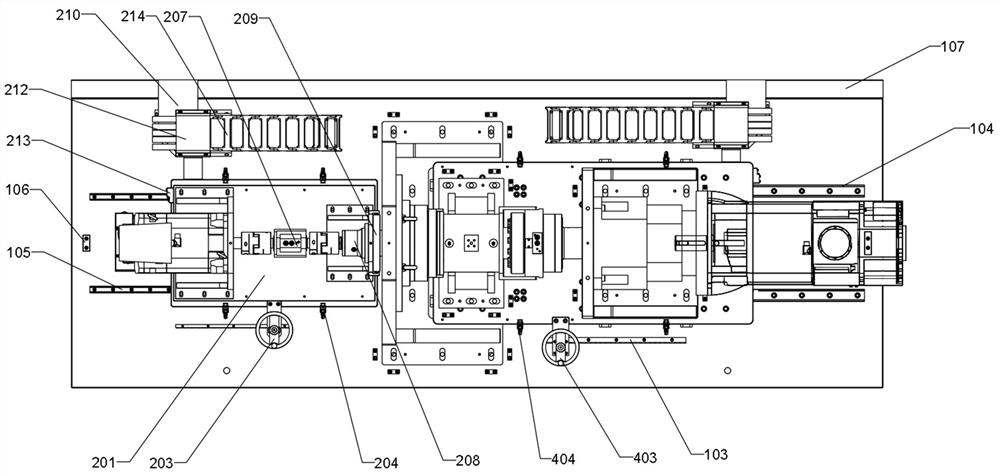

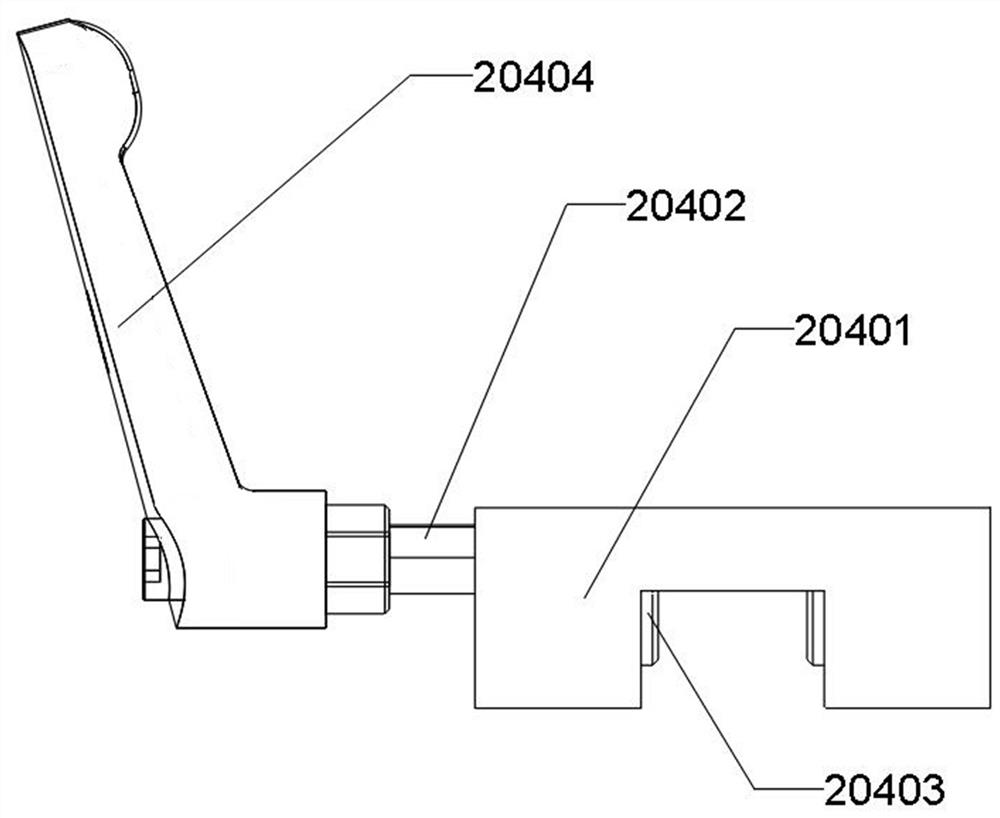

[0069] Such as Figure 1-Figure 6 Shown:

[0070] This embodiment provides an angle sensor installation tool, including a base assembly 1, a drive assembly 2 and a load assembly 4, wherein:

[0071] The base assembly 1 is set on the ground;

[0072] Both the drive assembly 2 and the load assembly 4 are arranged on the top of the base assembly 1;

[0073] A test fixture bracket 3 is also provided between the drive assembly 2 and the load assembly 4;

[0074] The drive assembly 2 includes a drive motor 202, a drive bearing bracket 206 and a drive bearing seat assembly 208;

[0075] The drive motor 202 is connected to the drive bearing seat assembly 208 through a drive shaft;

[0076] The drive bearing seat assembly 208 is installed and fixed on the drive bearing bracket 206;

[0077] The middle section of the drive shaft is provided with a torque sensor mounting frame, and the torque sensor mounting frame is provided with a torque speed sensor one 207;

[0078] The first t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com