Evaluation and detection method of heat-resistant, temperature-resistant and water-resistant terrace material

A floor material and detection method technology, applied in the direction of weather resistance/light resistance/corrosion resistance, analysis materials, measuring devices, etc., can solve the problems of high equipment cost, practical limitations, etc., to solve the technical blank, excellent high temperature resistance and water resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

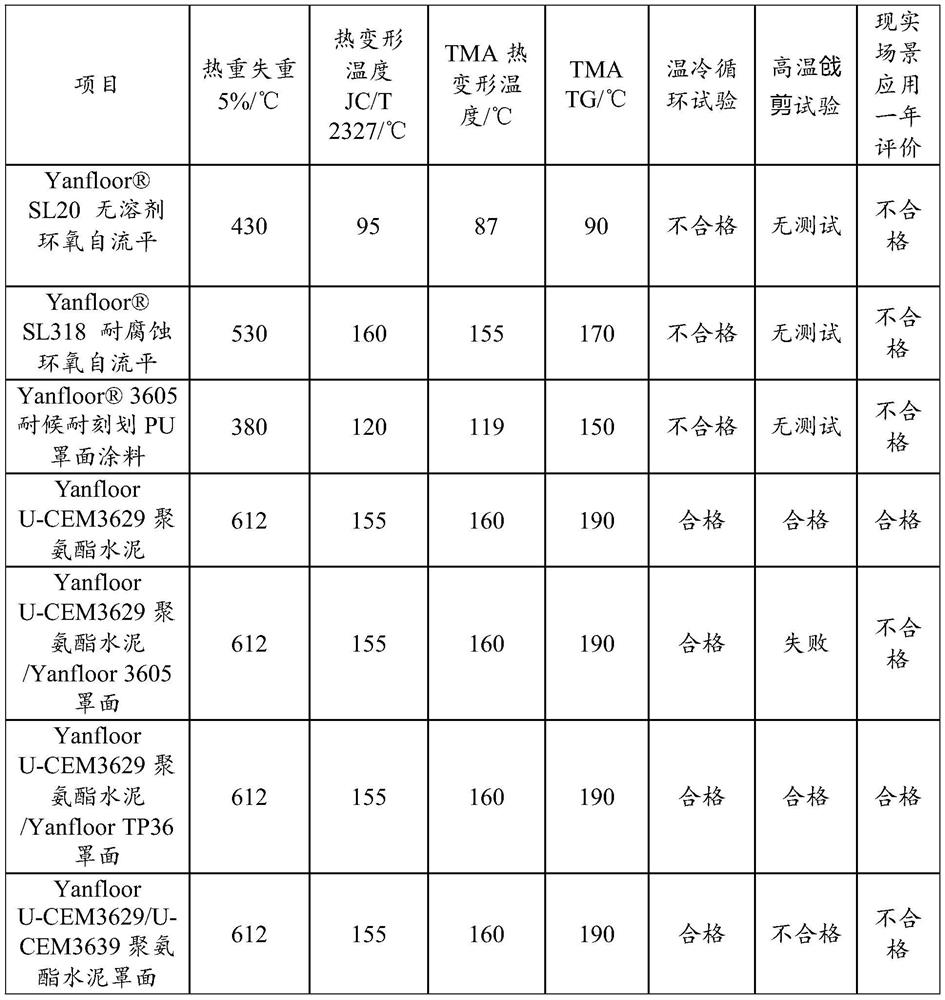

Examples

Embodiment 1

[0032] A method for evaluating and detecting heat-resistant, temperature-resistant and water-resistant floor materials, comprising the following steps:

[0033] S 1 1. Prepare the floor material to be tested, select the standard substrate concrete slab whose strength meets GB / T 22374-2018, and use the shot peening method to make the surface roughness of the substrate reach S3 level (you can use 60 mesh round sand for leveling) , lay the floor material on the surface of the concrete slab base material, and after curing for 7 days, use it as a sample of the floor material to be tested;

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com