Modularized OLED display eyepiece assembly

A modular and component technology, used in magnifiers, optical components, installation, etc., can solve the problems of scattered device structure, inconvenient design and installation, and inability to replace.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

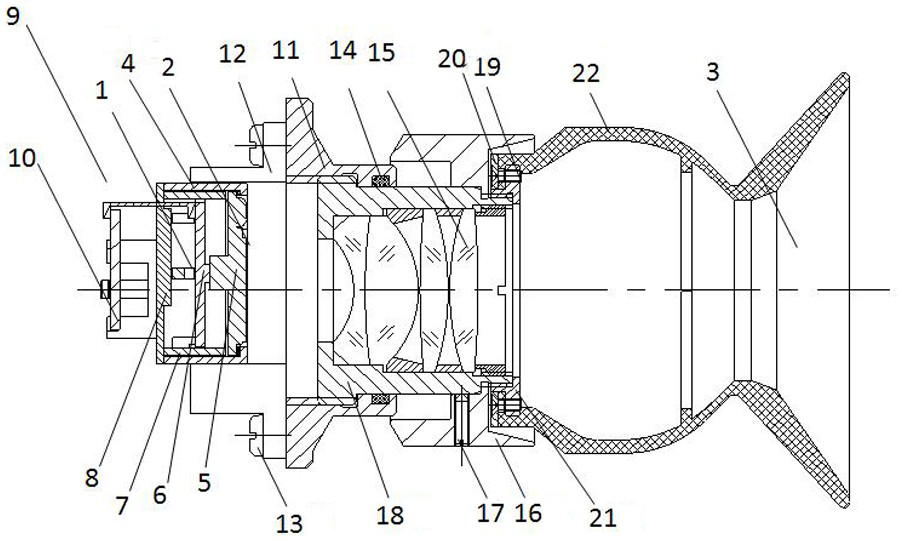

[0021] The present invention will be further described below in conjunction with accompanying drawing:

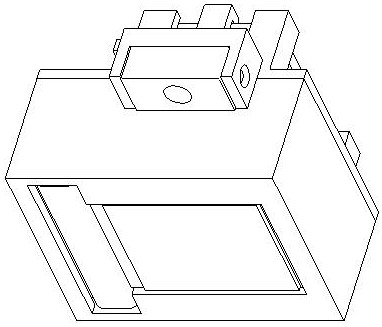

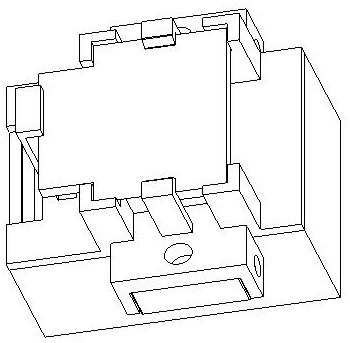

[0022] Such as Figure 1-5 As shown, a modular OLED display eyepiece assembly is composed of three modules: a display assembly 1, an eyepiece assembly 2 and a goggle assembly 3. A single module can be quickly replaced, suitable for products with different imaging requirements, and easy to install. The eyepiece The assembly 2 and the display assembly 1 are connected by first screws 13 , and the eyepiece assembly 2 and the shading eyewear assembly 3 are connected by threads. The eyepiece tube 18 of the eyepiece assembly 2 is provided with an external thread, and the goggle seat 21 of the shading assembly 3 is provided with an internal thread, and the eyepiece assembly 2 and the shading eye assembly 3 are connected to each other through the external thread and the internal thread.

[0023] The display assembly 1 includes a housing 4, a display screen 5, a driver board 6, a ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com