Structure and installation method of flow-through type profile tower plate

A profile and tray technology, which is applied in the structure and installation field of through-flow profile trays to prevent follow-up, improve efficiency, and solve problems in support and strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

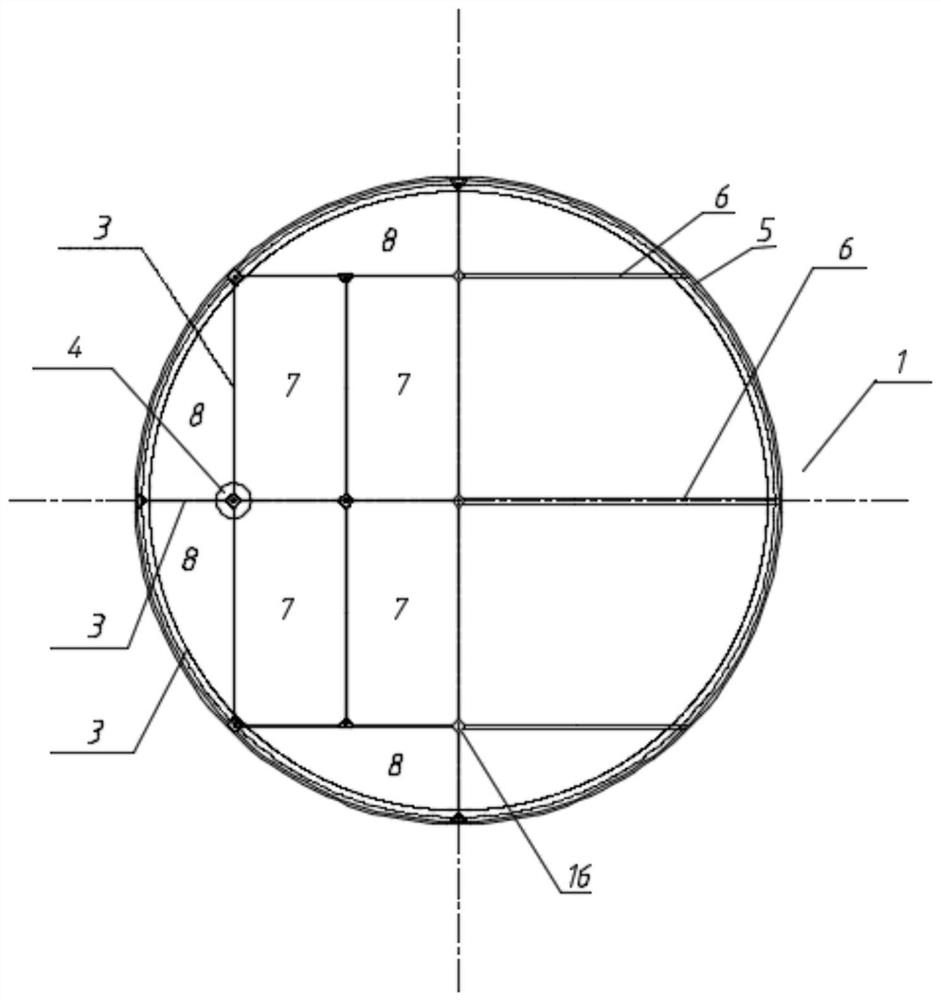

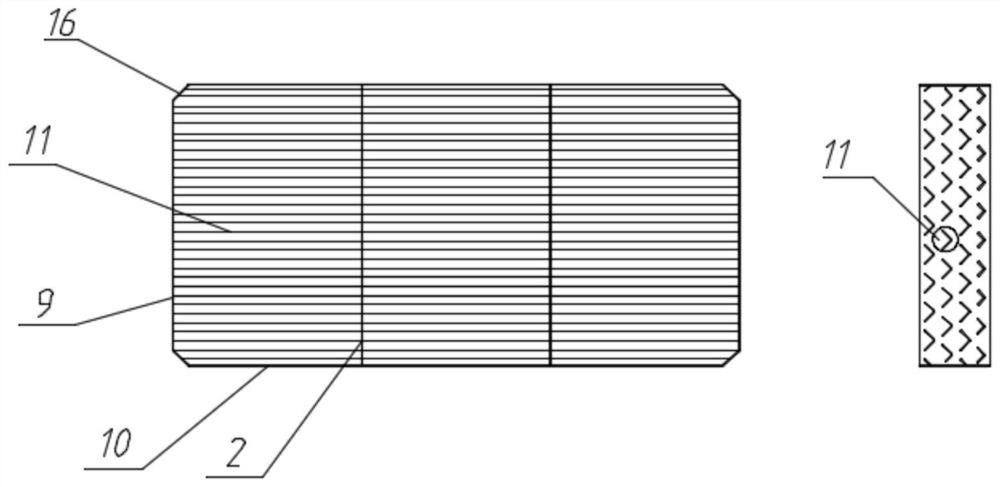

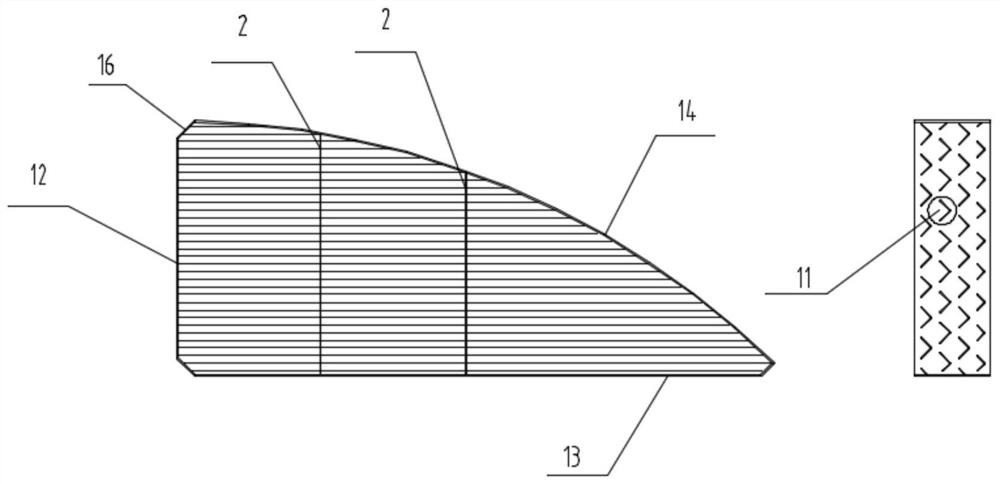

[0040] see Figure 1 to Figure 6 , a structure of a through-flow profile tray 1, including a rectangular tray sub-block 7 and an arc-shaped tray sub-block 8, a plurality of rectangular tray sub-blocks 7 and arc-shaped tray sub-blocks 8 are fixedly connected to the upper side of the support beam 6 and The inner area of the support ring 5 is assembled horizontally to form a tray.

[0041] In this embodiment, the support ring 5 is circular, and the area adjacent to the support ring 5 is assembled with arc-shaped tray sub-blocks 8 , and other areas are assembled with rectangular tray sub-blocks 7 .

[0042]The sub-block of the tower plate includes a side plate 3, a support plate 2 and an angle profile 11. A plurality of side plates 3 are connected in a closed loop. The end is arranged on the inner side of the side plate 3. In the vertical direction, there are multi-layered corner profiles 11 arranged in a stepped manner. The vertical spacing between two adjacent layers of corn...

Embodiment 2

[0050] Such as Figure 7 As shown, the difference between this embodiment and Embodiment 1 is that in the sub-block of the tray, the size of the uppermost profile is 0.5 to 0.8 times that of the other layers, so that the horizontal gap between the uppermost adjacent two profiles is larger than other profiles. The horizontal gap between two adjacent profiles on the top layer is the defoaming structure; the horizontal gap between the other layers of profiles ensures full contact between gas and liquid, and the horizontal gap between the top layer of profiles When the gas velocity increases, the gas velocity decreases, and the impurities and liquid droplets flow to the lower layer under the action of gravity to play the role of defoaming; this defoaming structure is a part of the structure of the tray itself, which has dual functions of separation and defoaming, and no additional installation is required. Demister, and each tray has a demister function, the demister efficiency is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com