Spraying equipment with robot and dragging teaching rod mechanism, and operation method thereof

A technology of dragging teaching and operation methods, which is applied in the direction of manipulators, spraying devices, manufacturing tools, etc., and can solve the problems of unsatisfactory use scenarios, limited quality, stiffness, speed and arm span, limited small size, light weight, and small range Production and application issues, to achieve the effect of reducing occupational disease hazards, wide application range, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

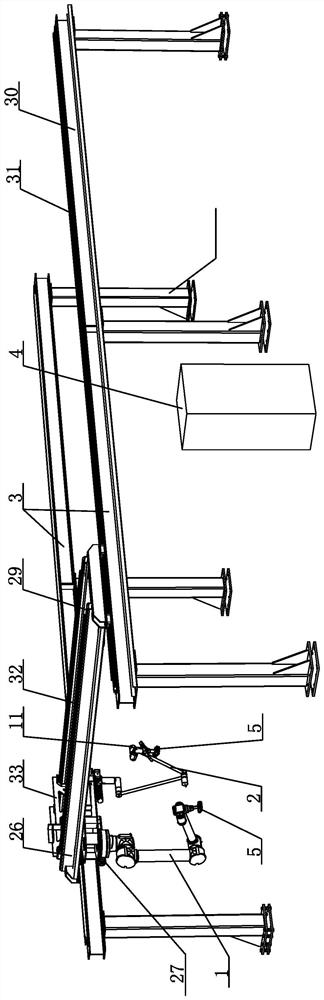

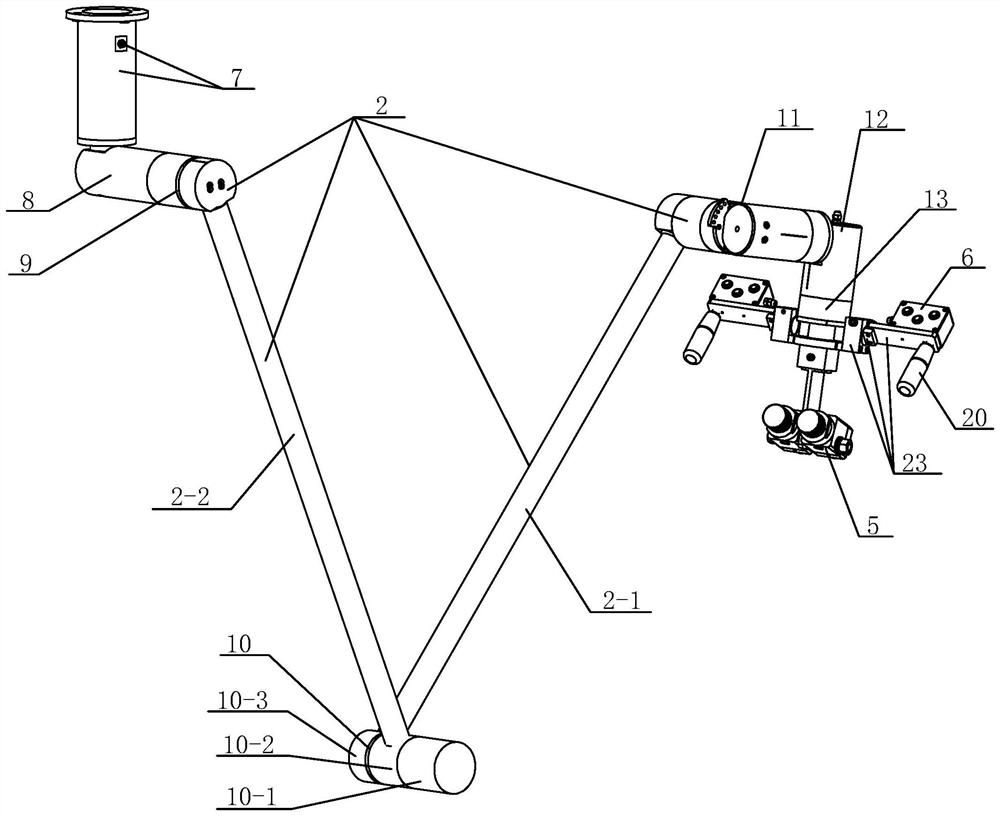

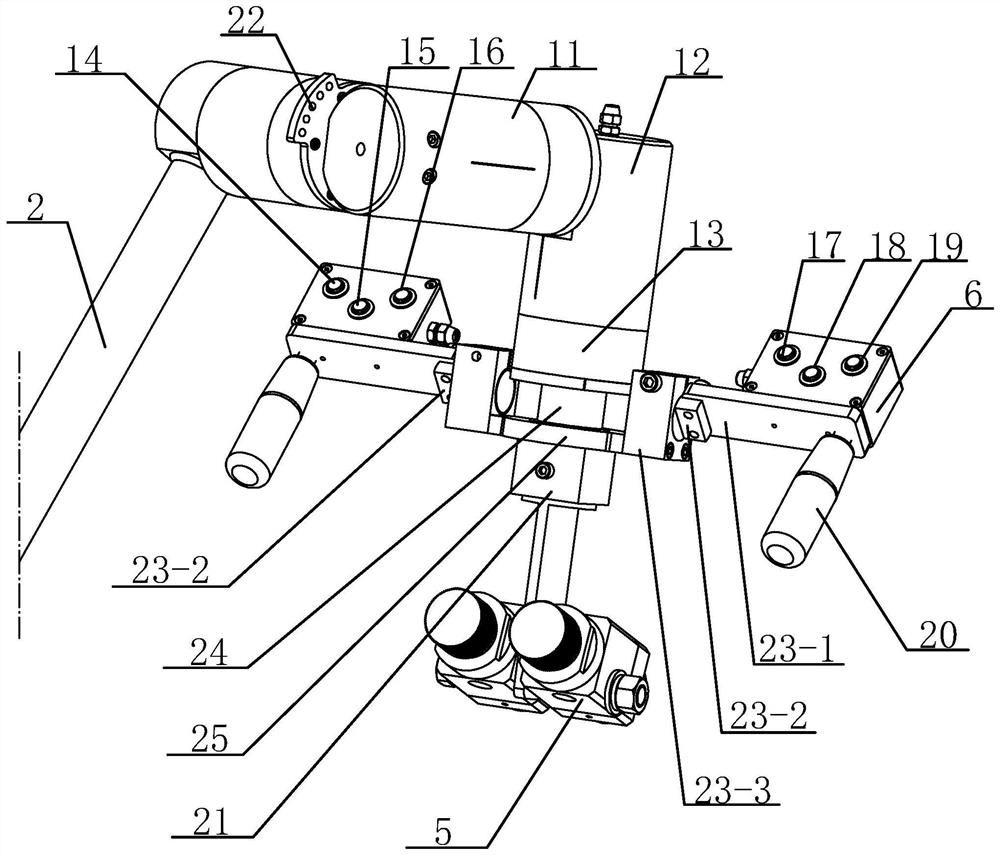

[0019] Embodiment, with reference to accompanying drawing, a kind of robot drags the spraying equipment of teaching rod mechanism and its operation method, comprises by six truss columns 28, fixes two parallel truss X beams 3 on the upper end of truss columns 28, is characterized in that A guide rail 30 is installed on the truss X beam 3, and a rack 31 is fixed on the guide rail 30; a truss Y beam 26 that moves left and right is installed on the rack 1 31, and a through-hole slideway is provided in the middle of the truss Y beam 26 Two racks 32 are fixed on both sides above 29; robot 1 and drag teaching rod mechanism 2 are installed in the through-hole slideway 29, and robot 1 and drag teaching rod mechanism 2 are fixed on the robot dragging teaching rod mechanism fixing seat 33, move back and forth in the through hole slideway 29.

[0020] The robot 1 includes that the robot 1 is fixed on the truss base 27 , and the spray gun 5 is fixed on the front arm of the robot 1 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com