Belt fastener with movable pressing block

A technology of movable pressing blocks and belt buckles, which is applied to buckles, fasteners, clothing, etc., can solve the problems of large distance adjustment, complexity, and difficulty in belt loosening, and achieves easy implementation, simple loosening operation, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

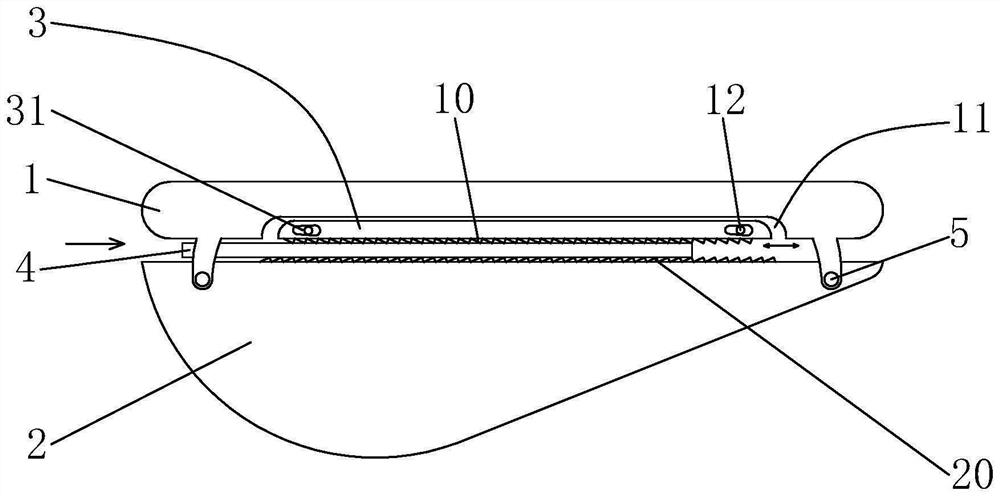

Embodiment 1

[0027] Embodiment 1: as figure 1 As shown, a belt buckle with a movable pressure block includes a belt buckle cover 1 and a button body 2, the belt button cover 1 is connected above the button body 2, and the top wall of the button body 2 is provided with a second The friction surface 20 is characterized in that it also includes a first movable pressing block 3, the first movable pressing block 3 is installed on the bottom of the belt cover 1 in a movable manner, and the first movable pressing block 3 and the second friction The distance between the surfaces 20 constitutes the gap for clamping the belt; this type of belt buckle with a movable pressing block is provided with a first movable pressing block 3 on the belt cover 1, through which the first movable pressing block 3 and the buckle body 2 The second friction surface 20 on the top is matched, and the belt 4 enters the clamping belt gap, and is pressed by the first movable pressure block 3 and the second friction surface...

Embodiment 2

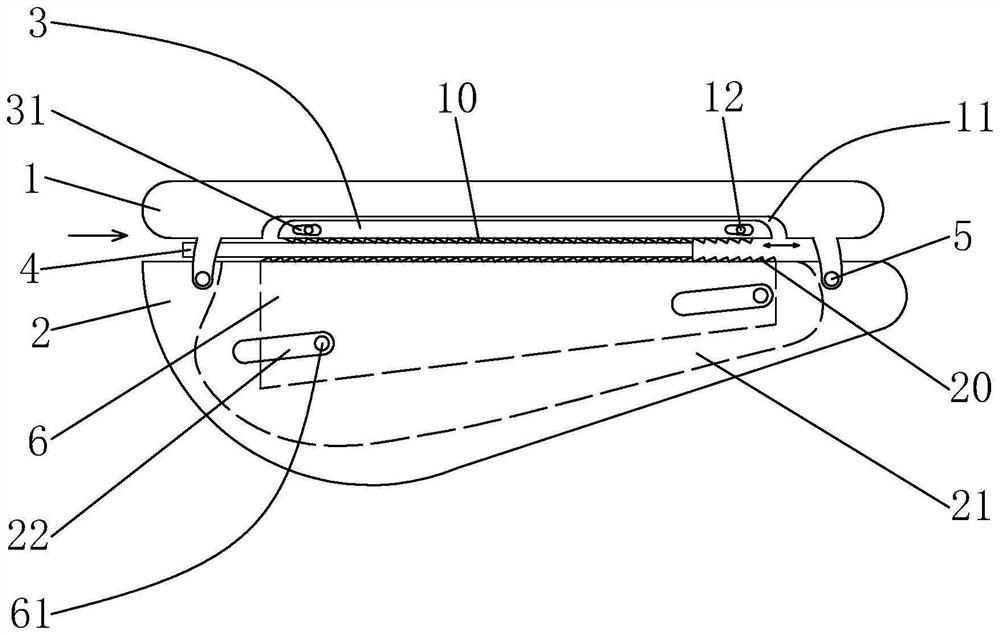

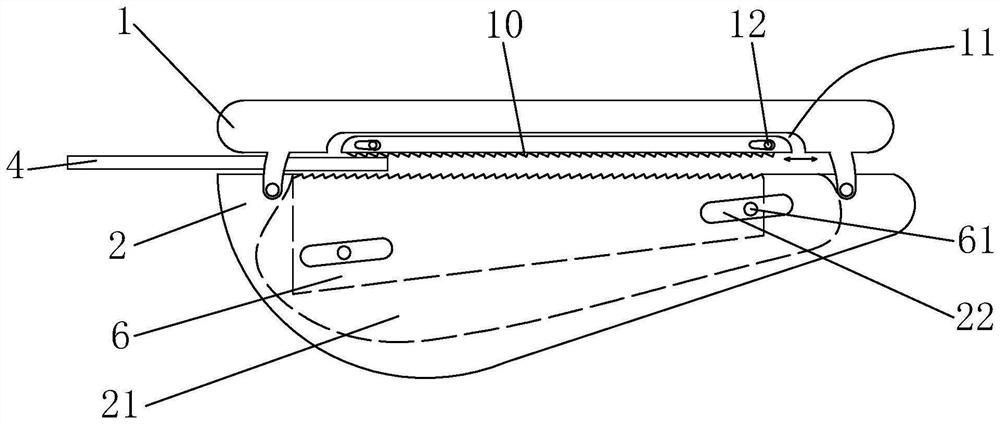

[0033] Embodiment 2: as figure 2 and image 3 As shown, this embodiment is similar to Embodiment 1, the difference is that: it also includes a second movable pressing block 6, the top of the button body 2 is provided with a second installation space 21, and the second movable pressing block 6 is embedded in the The second installation space 21, the top wall of the second movable pressing block 6 is provided with the second friction surface 20; the second friction surface 20 is arranged on the second movable pressing block 6, so that the second friction surface 20 can It moves along with the movement of the second movable pressure block 6 , so that the locking effect of the second friction surface 20 on the belt 4 is better, and at the same time, the movable second friction surface 20 also facilitates the loosening of the belt 4 .

[0034]In this embodiment, the button body 2 is provided with an inclined chute 22, the second movable pressing block 6 is fixed with a second fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com