Self-locking bolt assembly

A bolt assembly and self-locking technology, which is applied in the direction of locking fasteners, bolts, threaded fasteners, etc., can solve problems such as inconvenient use, reduced mechanical strength of bolts, and increased cost of bolts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

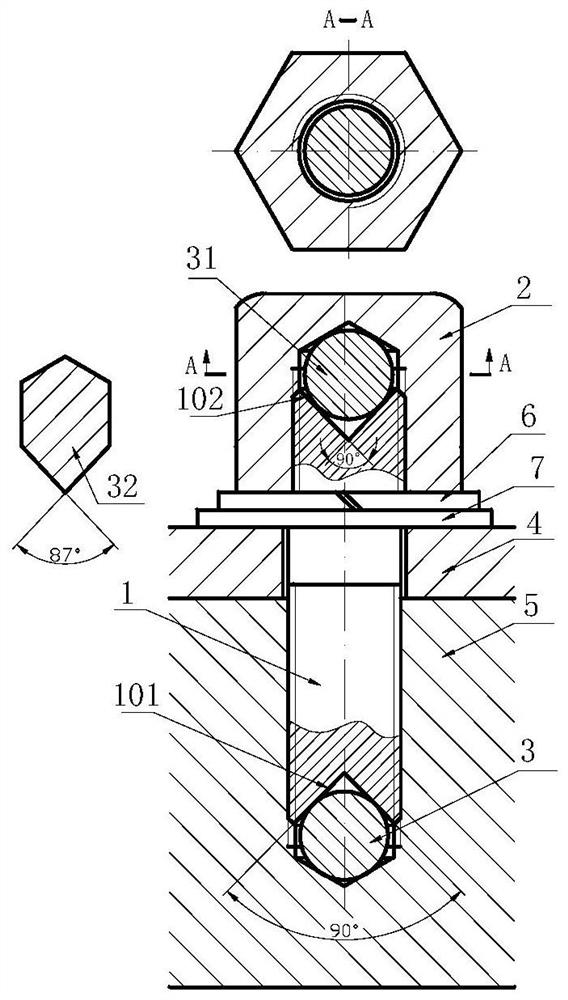

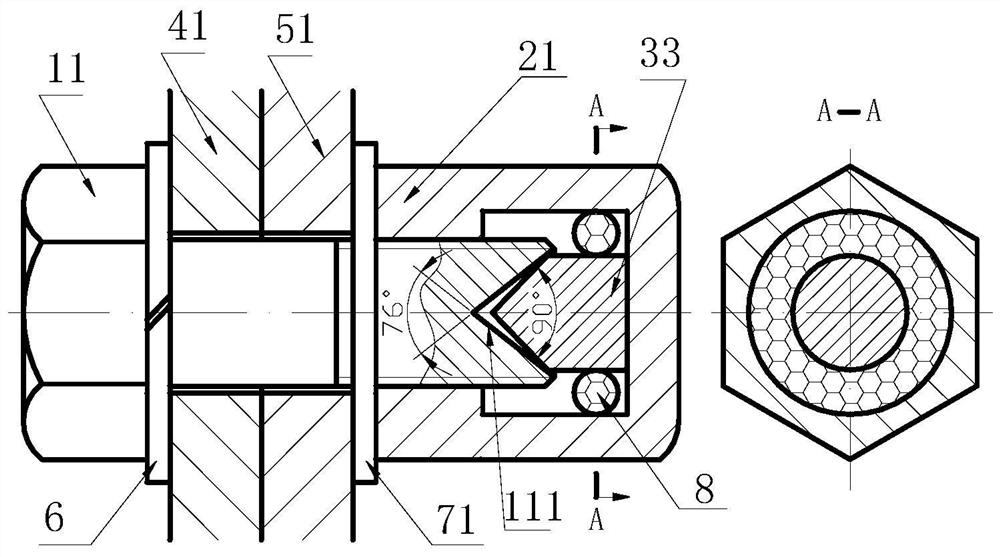

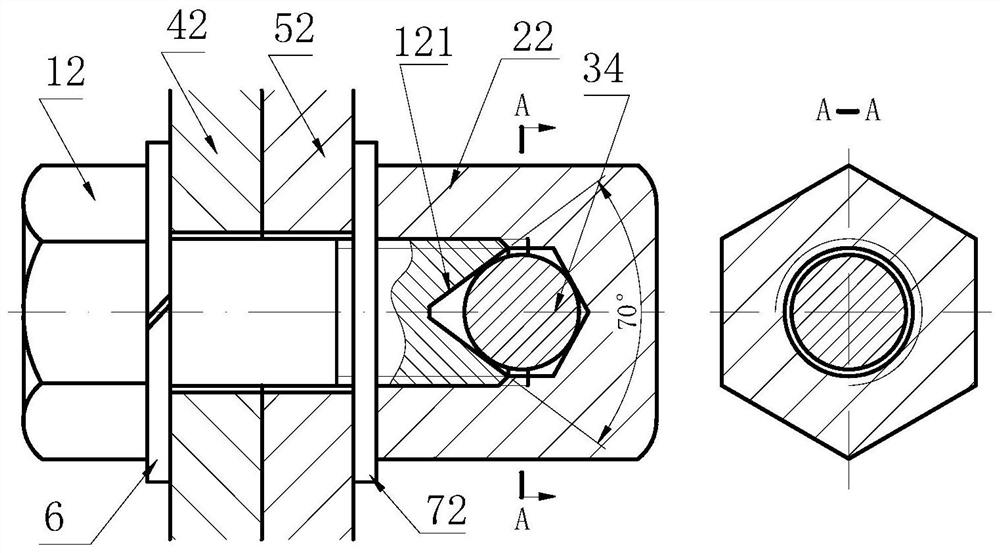

[0010] combine figure 1 , the two ends of the stud bolt 1 have tapered sockets, the conical angles of the tapered sockets 101 and 102 are both 90 degrees, the thread of the blind hole of the fastened part 5 is matched with the thread of the stud bolt 1, using The metal ball expansion block 3 whose diameter is slightly smaller than the diameter of the round hole is put into the thread of the blind hole, the stud bolt 1 is added to the spring washer 6 and the adjustment flat washer 7 and passes through the opening of the connected part 4, and screwed into the connected part In the thread of the blind hole of part 5, a pad 32 without locking function is put into the tapered socket 102 at the outer end of the stud bolt. Since the taper angle of the pad 32 is less than 90 degrees, in this example The taper angle is 87 degrees, and there will be no radial expansion force when placed in the taper socket 102 of the bolt 1; the cap nut 2 is screwed into the outside of the stud bolt 1, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com