Stool forming method

A molding method and technology for sitting stools, which can be applied to stools, clothing, and other seating furniture, etc., can solve the problems of rigid modeling of stools, easy breakage of stools, and not enough beauty and fashion, so as to improve comfort and increase childlikeness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

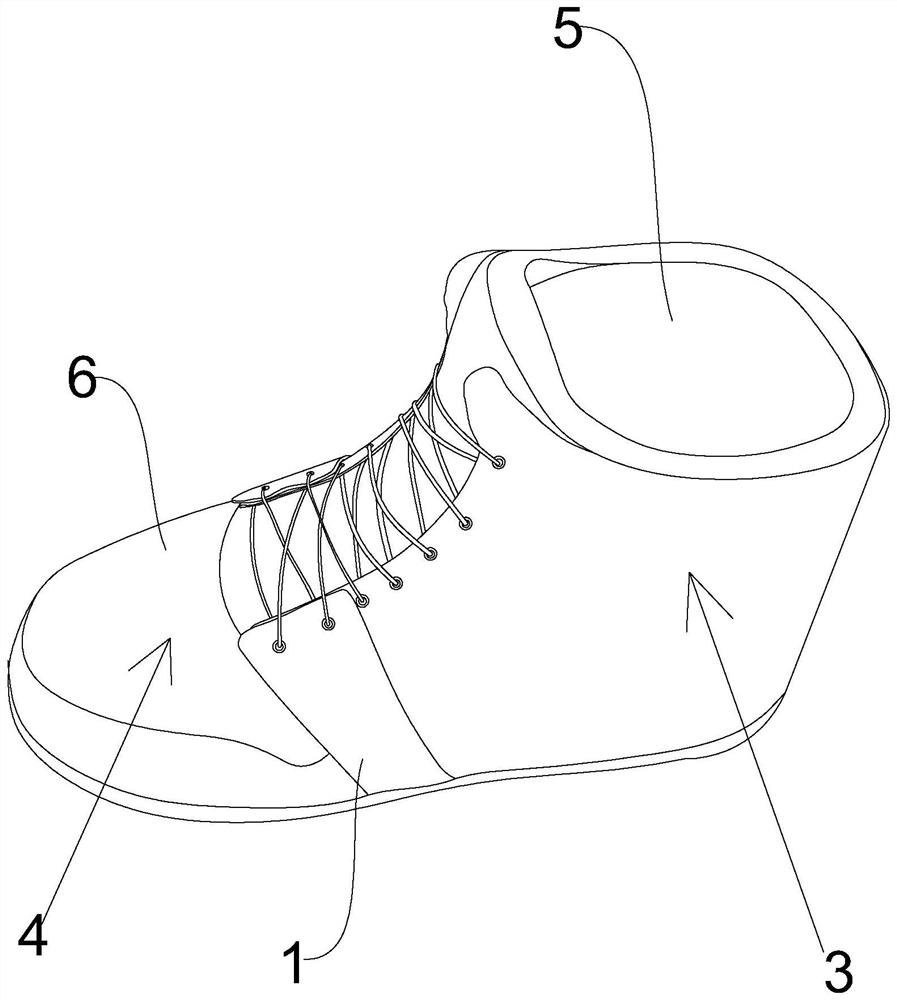

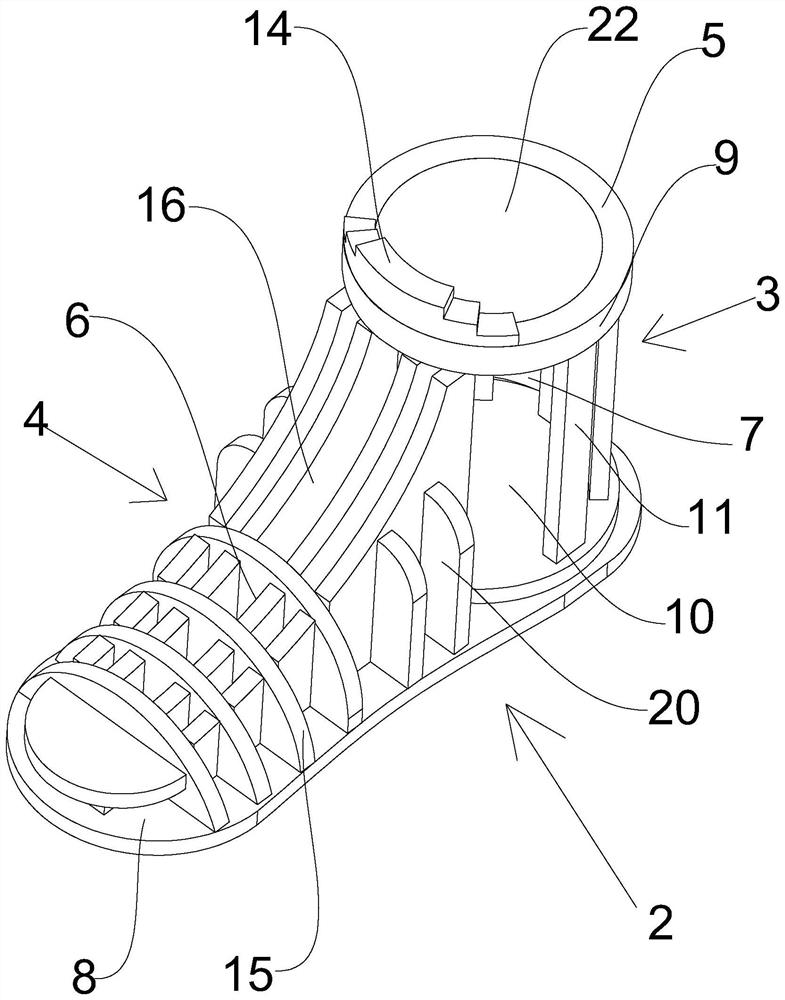

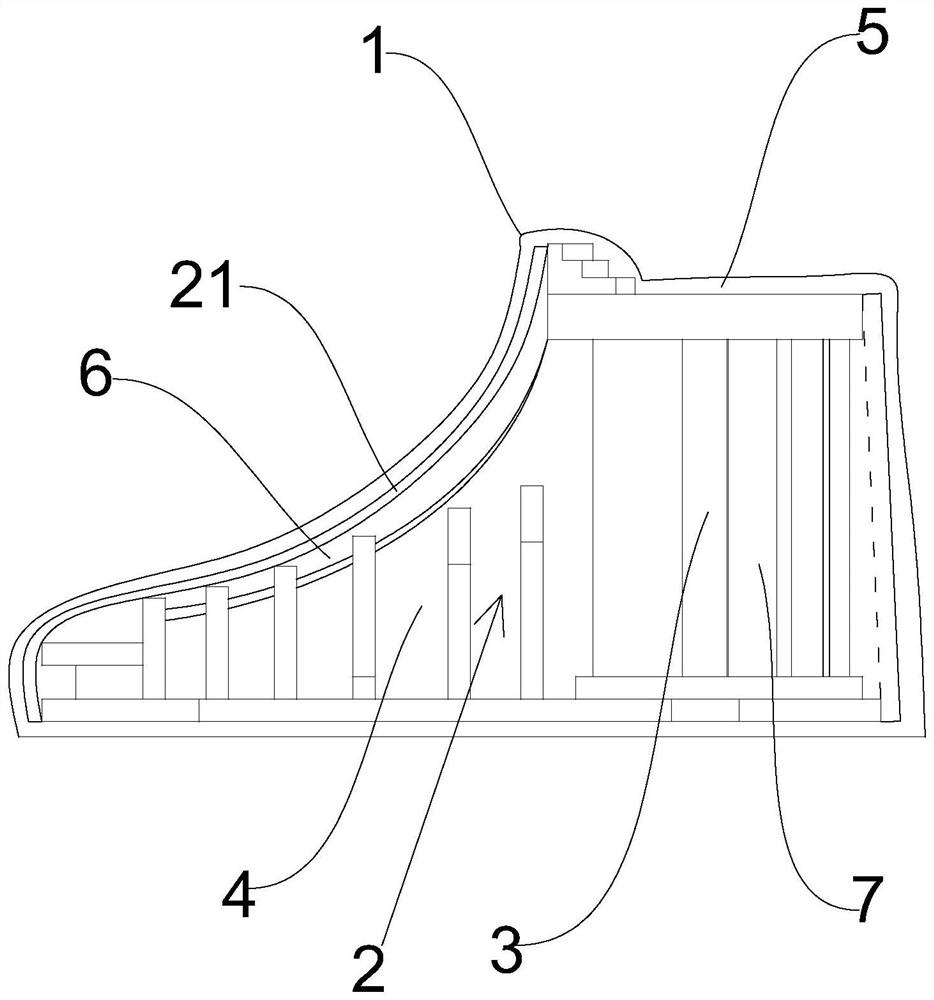

[0043] Example: such as Figure 1-5 As shown, the present invention firstly provides a shoe-shaped stool, that is, the final product, which includes a jacket 1 and a stool body 2 , and the jacket 1 is wrapped outside the stool body 2 . The stool body 2 has a head end and a tail end along its own length direction, and the stool is provided with a first bearing part 3 at its own tail end, and the first bearing part 3 forms a first bearing area 5 on its top surface; the user can bear Sit on the first bearing area 5 to rest or wear shoes.

[0044] At the same time, if figure 1 with figure 2 As shown, the stool has a second load-bearing portion 4 extending toward the front end of the stool body 2 on the side of the first load-bearing portion 3 facing the head end of the stool, and the second load-bearing portion 4 is lower than the first load-bearing portion 3 as a whole , the top surface of the second bearing part 4 protrudes from the top side wall of the first bearing part 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com