Side comb plate mechanism of crusher, and crusher

A technology of crushers and combs, which is applied in the field of side comb mechanisms and crushers, can solve the problems of material accumulation and unsmooth discharge, and achieve the effect of preventing material accumulation, preventing effect, and avoiding material accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

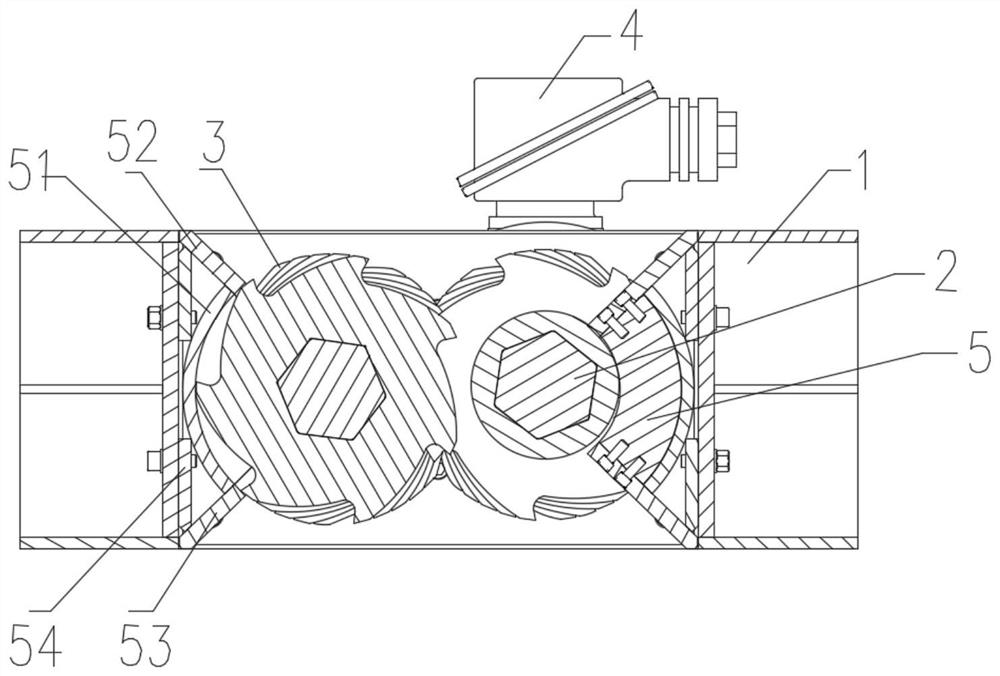

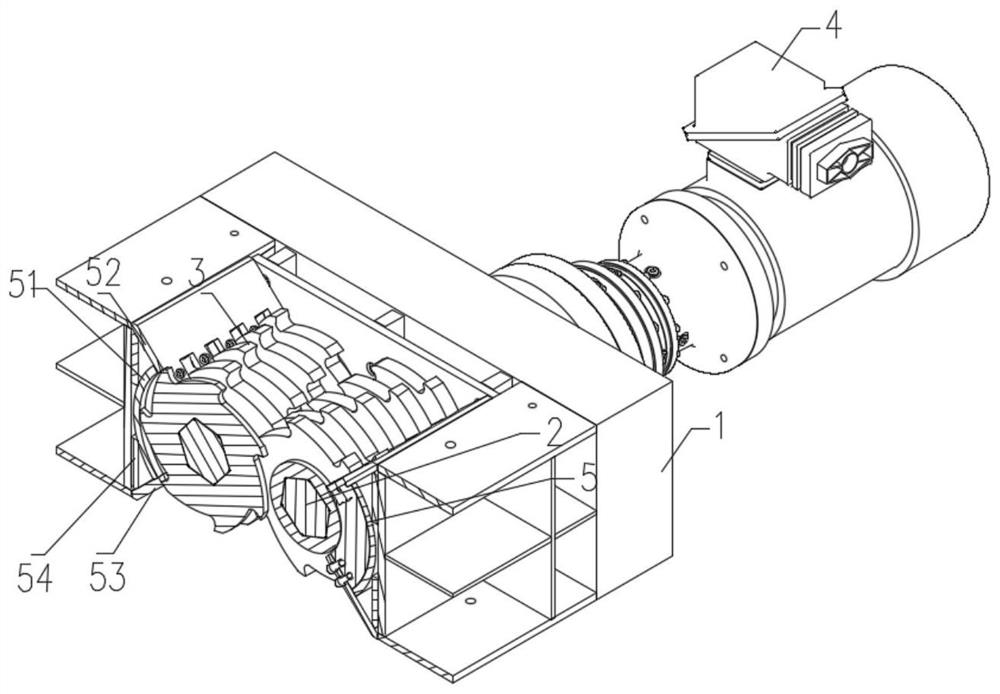

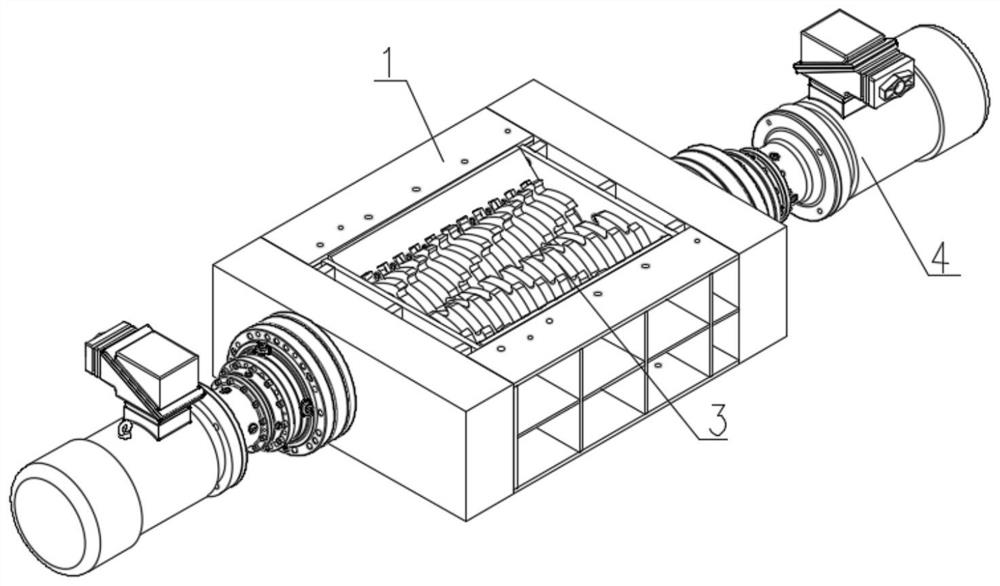

[0058] Such as figure 1 , 2 , 3, the crusher described in this embodiment includes:

[0059] broken box 1,

[0060] The cutter shaft 2 is arranged in the crushing box 1;

[0061] A plurality of cutters 3 are arranged on the cutter shaft 2;

[0062] a driving part 4, used to drive the rotation of the cutter shaft 2;

[0063] The side comb mechanism 5 of the crusher is arranged on the inner wall of the side wall of the crushing box 1, and includes an installation part connected to the inner wall of the crushing box and a plurality of combs sequentially arranged on the inner wall of the installation part;

[0064] Such as Figure 4 As shown, the installation part includes: a wall plate 51, an upper cover plate 52, a lower cover plate 53 and a mounting plate 54. The inner wall of the wall plate 51 is adapted to the orbit of the cutter 3 of the crusher, and the inner wall of the wall plate 51 is compatible with the There is a predetermined gap between the trajectories of the...

Embodiment 2

[0069] This embodiment provides another implementation of the side comb mechanism.

[0070] The rest of the structure of the side comb mechanism of the crusher is the same as that of Embodiment 1, the difference being:

[0071] The cross-section of the wall plate 51 is a multi-segment linear shape approaching the arc shape, the center of the arc shape is located on the side where the comb plate is located, and the circle where the arc shape is located is related to the rotation of the head of the cutter of the crusher. The trajectory is a concentric circle, and the radius of the circle where the arc is located is slightly larger than the radius of the turning trajectory of the head of the crusher cutter.

[0072] Specifically, the polyline can be Figure 5 The 3 line segments shown connect; Image 6 The 4 line segments shown connect; Figure 7 The 5 line segments shown connect and so on. Specifically, the multi-segment line shape can be formed by continuous welding of mult...

Embodiment 3

[0075] In this embodiment, the cutter 3 is a two-way cutter, and there is a preset gap between the cutter 3 and the adjacent comb plate 55, so that the cutter 3 of the crusher forms a shearing structure with the mounting part or the adjacent comb plate 55 , that is, the cutter 3 is a moving knife, and the comb plate 55 or the upper cover plate 52 and the lower cover plate 53 of the installation portion are stationary fixed knives, specifically the top edge of the comb plate 55 or the upper cover plate 52 and the lower cover plate 53 The two sides of the side edge form a moving and fixed knife shearing structure, which increases auxiliary crushing for the crusher and improves the crushing capacity of the crusher.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com