Automatic edge folding machine for metal composite plate curtain wall plate

A technology for metal composite panels and curtain wall panels is applied in the field of hemming equipment manufacturing, which can solve the problems of low work efficiency and high labor intensity, and achieve the effects of easy operation, reduction of defective products, and easy promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

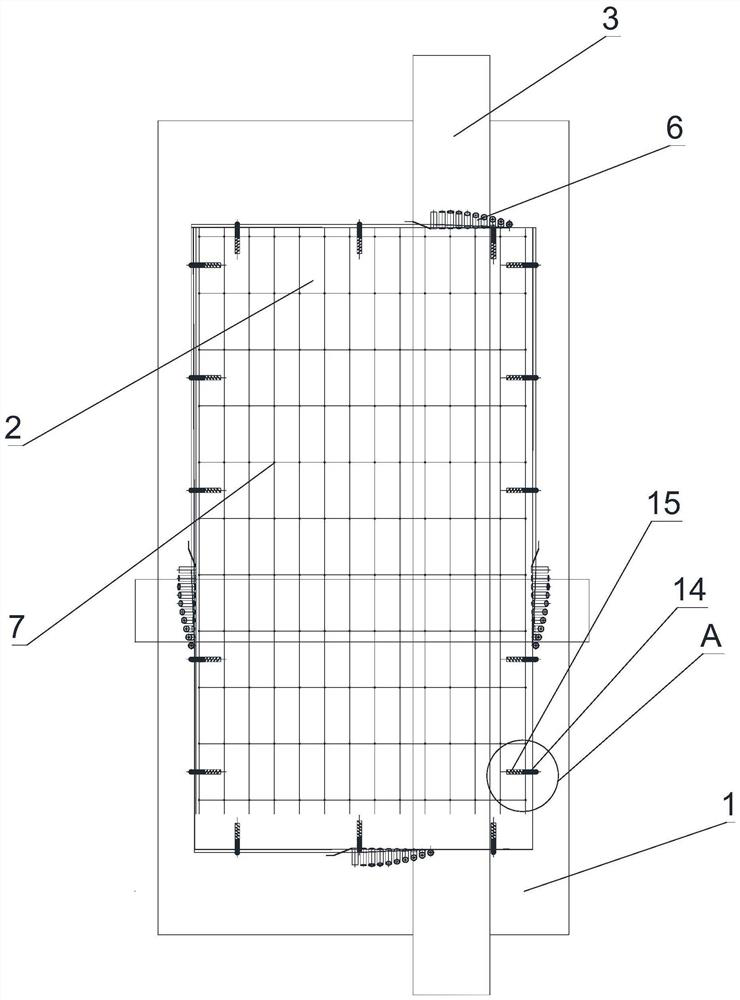

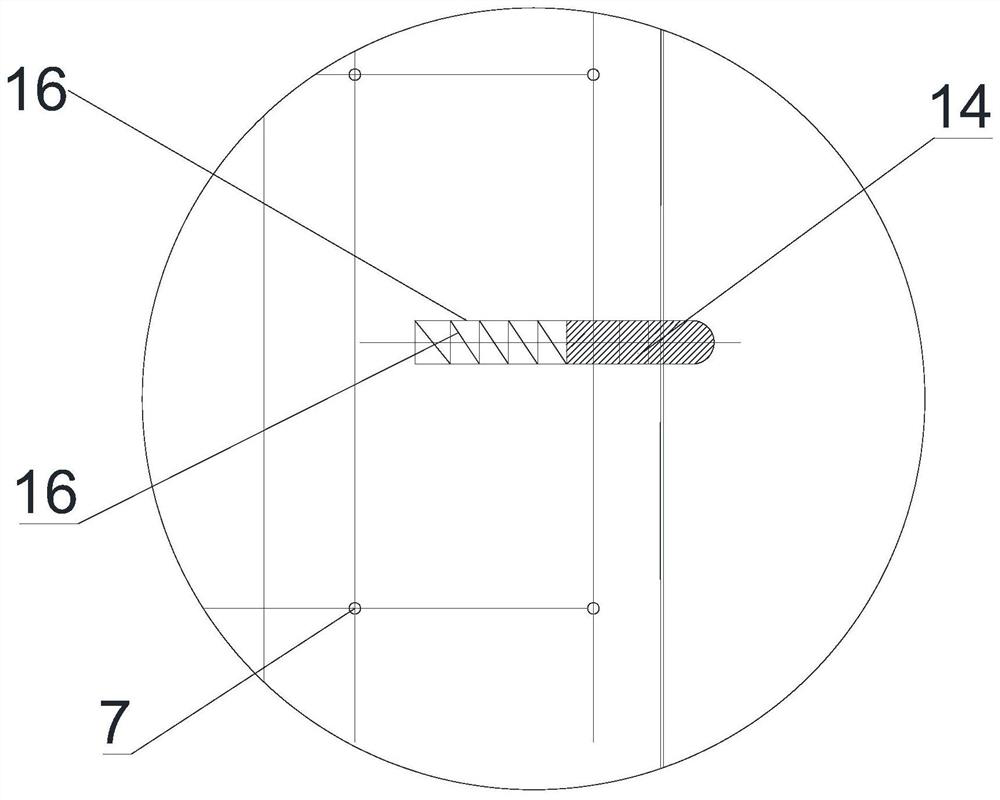

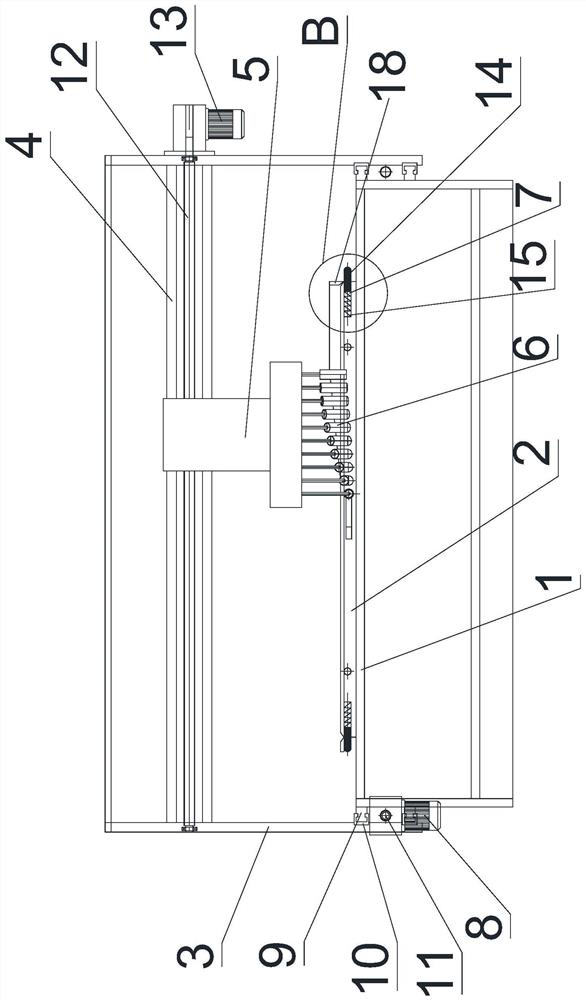

[0025] see Figure 1-5 , an automatic edge folding machine for metal composite panel curtain wall panels, comprising a support platform 1, a workbench 2 arranged on the surface of the support platform 1, the A gantry 3 is slidingly provided, and the workbench 2 is located in the gantry 3, and a negative pressure device is provided on the working surface of the workbench 2, and the side wall of the workbench 2 is provided with a telescopic support device, the telescopic support device is perpendicular to the side wall of the workbench 2, the beam 4 of the gantry 3 is provided with a mobile frame 5 outside the workbench, and the support platform 1 is also provided with a gantry sliding Driving device, the bottom end of the mobile frame 5 is provided with a guide wheel set facing the workbench 2, and the angle between the axis of the guide wheel 6 and the working surface from the beginning of the guide wheel set to the terminal end and the working surface is sequentially changed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com