Automatic cutting and welding system for repairing hammerhead of crust breaker

A welding system and automatic cutting technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of inability to automate welding, low efficiency, poor quality, etc., achieve good alignment, improve efficiency, and weld positioning accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to more fully explain the implementation of the present invention, implementation examples of the present invention are provided. These implementation examples are only illustrations of the present invention, and do not limit the scope of the present invention.

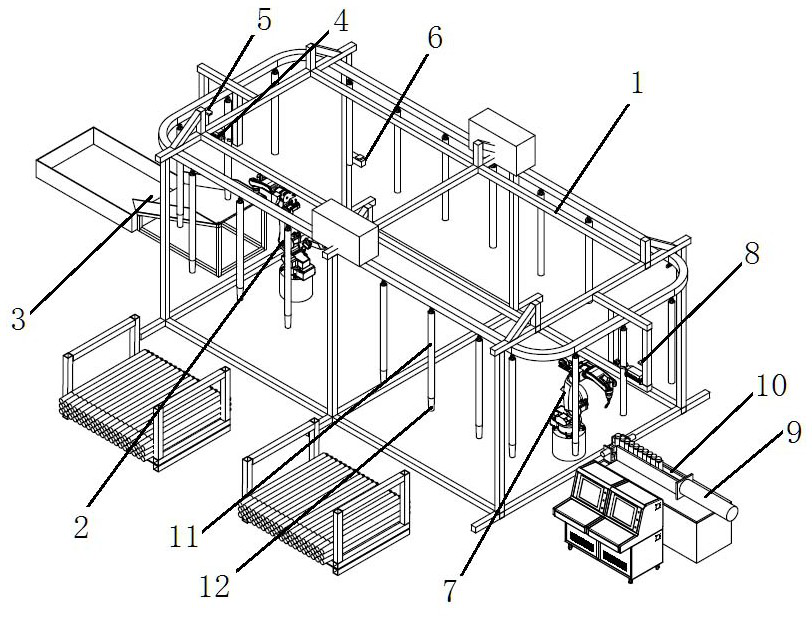

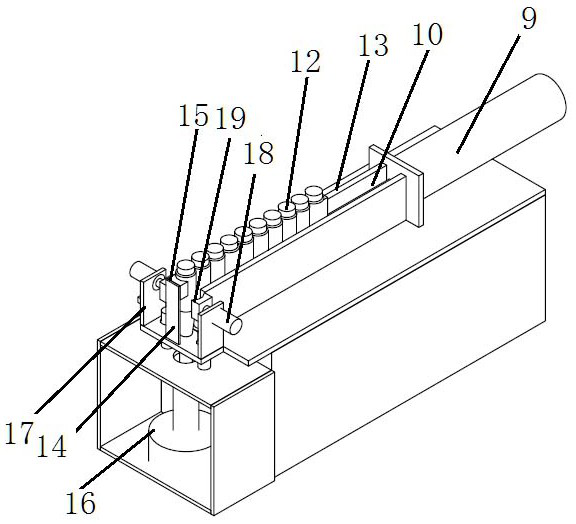

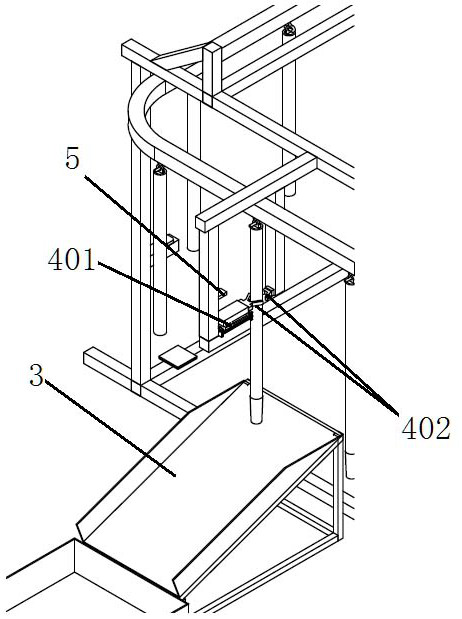

[0020] A further detailed explanation of the present invention is given in conjunction with the accompanying drawings. In the accompanying drawings, each label is: 1: circular conveyor; 2: cutting robot; 3: hammer head collecting bucket; 4: cutting clamping positioning mechanism; 401: linear module; 402 : clamp block; 5: first material detection sensor; 6: third material detection sensor; 7: welding robot; 8: second material detection sensor; 9: stepping oil cylinder; 10: long groove; 11: hammer rod; 12 : Hammer head; 13: Push rod; 14: Limiting plate; 15: Limiting block; 16: Lifting cylinder; 17: U-shaped frame; 18: Clamping cylinder; 19: Clamping block; 20: Connecting plate; 21 : bearing seat; 22: ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com