Metal part polishing device

A technology of metal parts and grinding mechanism, which is applied in the direction of grinding drive device, grinding automatic control device, metal processing equipment, etc., which can solve the problems of human injury, difficulty in grinding, and insufficient efficiency, etc., so as to reduce re-use The effect of grinding, simple structure and simple device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings in the embodiments of the present invention:

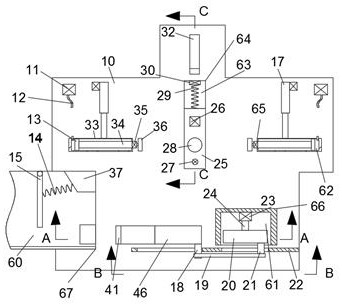

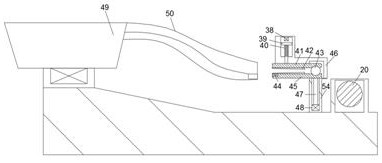

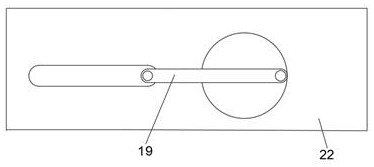

[0020] refer to Figure 1-Figure 4 According to an embodiment of the present invention, a metal parts grinding device includes a casing 10, a control chamber 63 communicating with the outside world is provided in the casing 10, and a control chamber 63 communicating with the outside world is provided in the lower end wall of the control chamber 63. The connecting rod chamber 61, the front end surface of the casing 10 is slidingly connected with two symmetrical sleeve rods 33, the sleeve rods 33 are provided with a moving chamber 62, the upper end surface of the casing 10 is provided with a shock plate 49, the The shock plate 49 is fixedly connected with a guide rail 50, the guide rail 50 is provided with an orientation cavity 60 communicating with the outside wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com