Phase-change temperature self-adjusting asphalt mixture for road and preparation method of phase-change temperature self-adjusting asphalt mixture

A technology of asphalt mixture and phase change temperature, which is applied in the field of asphalt mixture, can solve problems such as rutting, reduce road performance and service quality of the road surface, and achieve the effect of wide application prospects, low cost, and no rutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

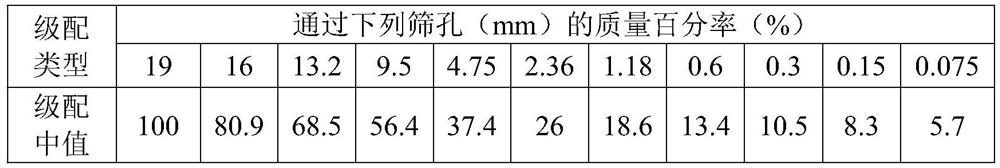

Method used

Image

Examples

Example Embodiment

[0038] Example 1

[0039] (1) The aggregates and mineral powders were dried at 105 ° C for 5 h, respectively, and the AH-70 asphalt and φ101.6 mm × 63.5mm cylindrical molding die were heated at 165 ° C for 2 h.

[0040] (2) The stirring pan was added to 165 ° C, and 108.3 parts of the drying collector was stirred, and then 5.2 parts of dried AH-70 asphalt mixing 90s;

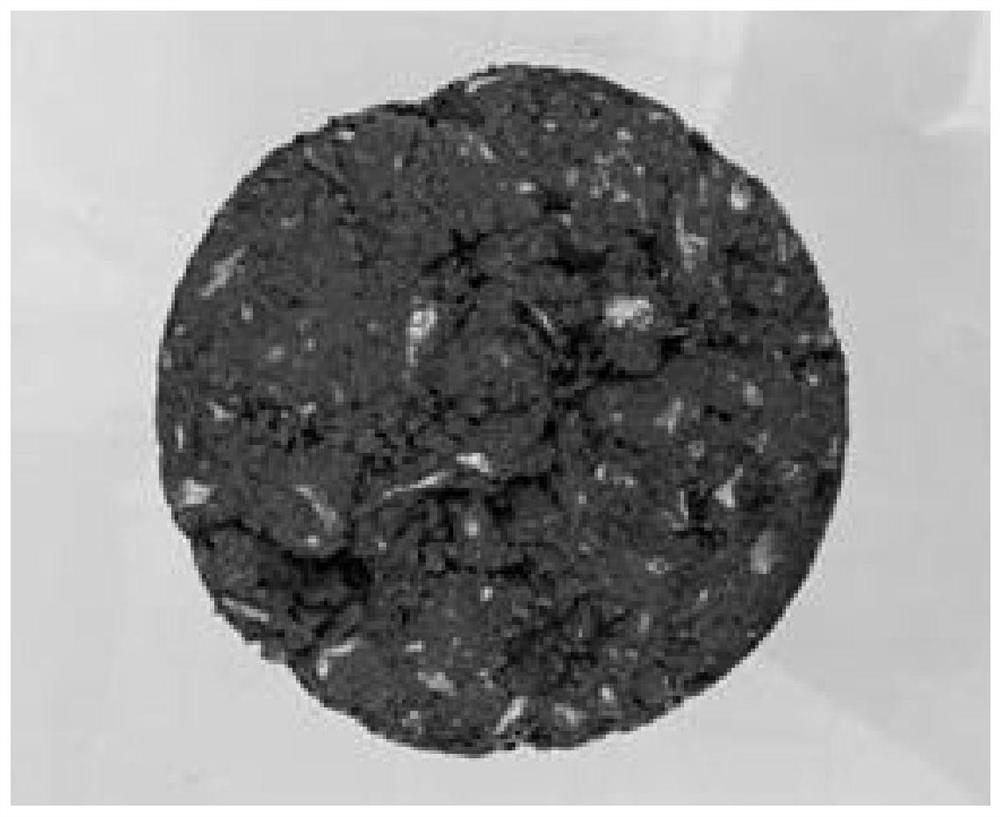

[0041] (3) Finally, 0.3 parts of the composite phase change material and 6.2 parts of dried mineral powder were added, and the stirring was continued to obtain a road phase change temperature self-adjusted asphalt mixture. Place the asphalt mixture into the molding mold, and prepare a standard Marshall test piece according to the "Highway Engineering Asphalt and Asphalt Mixed Test Procedures" JTG E20-2011 T0702-2011 Asphalt Mix Test Sub-Making Method (Hits) Magnography figure 2 .

[0042] Test 1: Outdoor cooling test

[0043]The passage from the adjustment phase transition temperature of asphalt mix and the common c...

Example Embodiment

[0053] Example 2

[0054] (1) the aggregate and mineral filler are dried for 6h at 100 ℃, the AH-70 asphalt φ101.6mm × 63.5mm cylinder and mold are heated for 2h at 165 deg.] C;

[0055] (2) the mixing pot was raised to 165 ℃, was added 107.5 parts of the current collector and drying the material was stirred for 90s, AH-70 was added 6 parts of the dried pitch was stirred 90s;

[0056] (3) Finally, 0.42 parts of mineral powder composite phase change material and 6.5 parts by drying, stirring was continued for 90s, to give a phase transition temperature from road regulation asphalt, into the forming mold, and press the "road asphalt and asphalt mixture test procedures "standard Marshall specimens prepared in JTG E20-2011 T0702-2011 asphalt specimen manufacturing method (compaction process).

Example Embodiment

[0057] Example 3

[0058] (1) the aggregate and mineral filler are dried 4h at 110 ℃, the AH-70 asphalt φ101.6mm × 63.5mm cylinder and mold are heated for 2h at 165 deg.] C;

[0059] (2) the mixing pot was raised to 165 ℃, was added 108.6 parts of the current collector and drying the material was stirred for 90s, AH-70 asphalt was added 4.8 parts by drying after stirring 90s;

[0060] (3) Finally, 0.6 parts of mineral powder composite phase change material and 5.9 parts by drying, stirring was continued for 90s, to give a phase transition temperature from road regulation asphalt, into the forming mold, and press the "road asphalt and asphalt mixture test procedures "standard Marshall specimens prepared in JTG E20-2011 T0702-2011 asphalt specimen manufacturing method (compaction process).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com