Paving construction method for greening garden landscape pavement engineering

A construction method and landscape technology, applied in the direction of road surface cleaning, roads, roads, etc., to achieve the effect of increasing compaction, improving efficiency, and avoiding shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Such as Figure 1-9As shown, the present embodiment provides a method for laying pavement engineering of greening garden landscape, comprising the following steps:

[0040] S1. Ground treatment: Excavate the road surface of the green garden landscape, and level the roadbed after excavation to obtain the grassroots;

[0041] S2. Coarse sand laying: laying 2 to 3 cm of coarse sand on the base layer to obtain a coarse sand layer;

[0042] S3. Cement mortar laying: through the laying construction device of the greening garden landscape pavement project, holding the hand lever 17, the installation box 10 moves or turns under the action of the walking wheel 13 and the auxiliary wheel 16; add cement mortar into the feed trough 21 , the cement mortar enters the collecting tank 22, is discharged through the discharge pipe 23 in a regular and orderly manner, and is neatly laid on the coarse sand layer, and the cement mortar with a thickness of 5-7cm is laid;

[0043] S4. Compac...

Embodiment 2

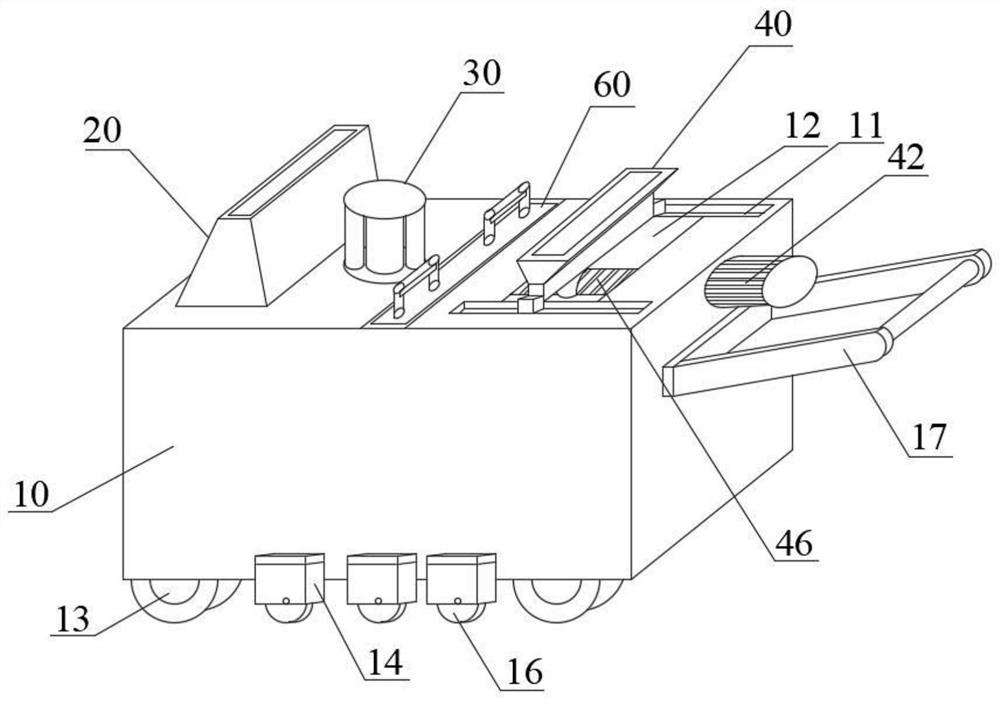

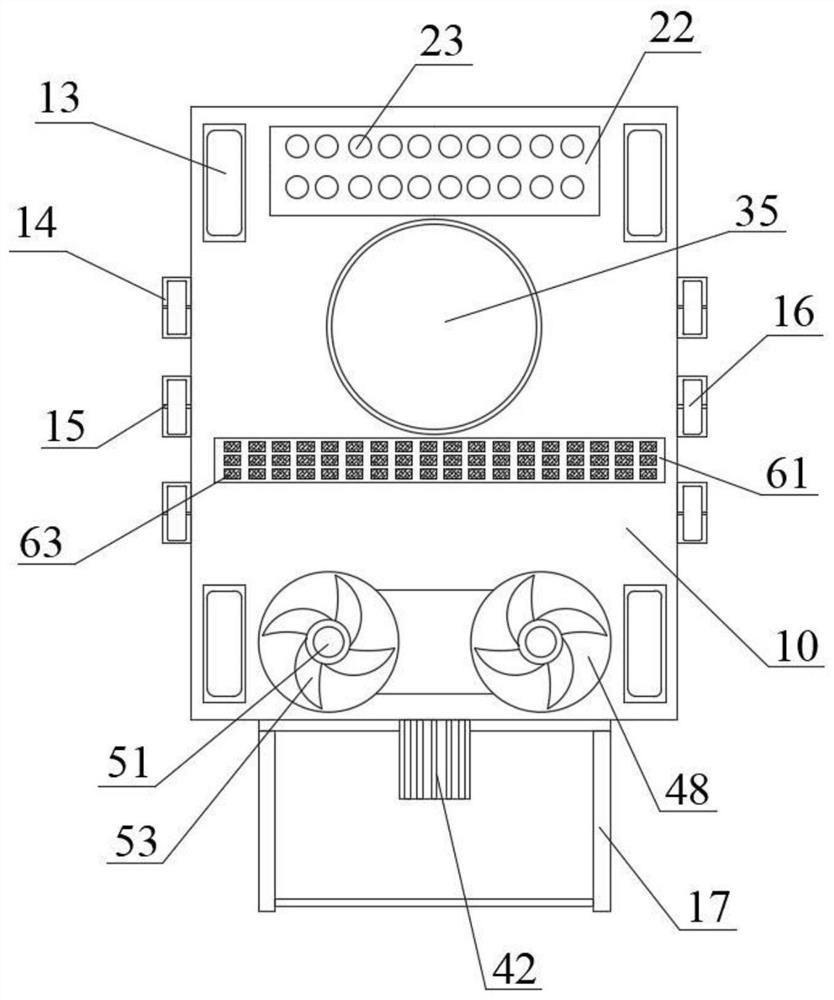

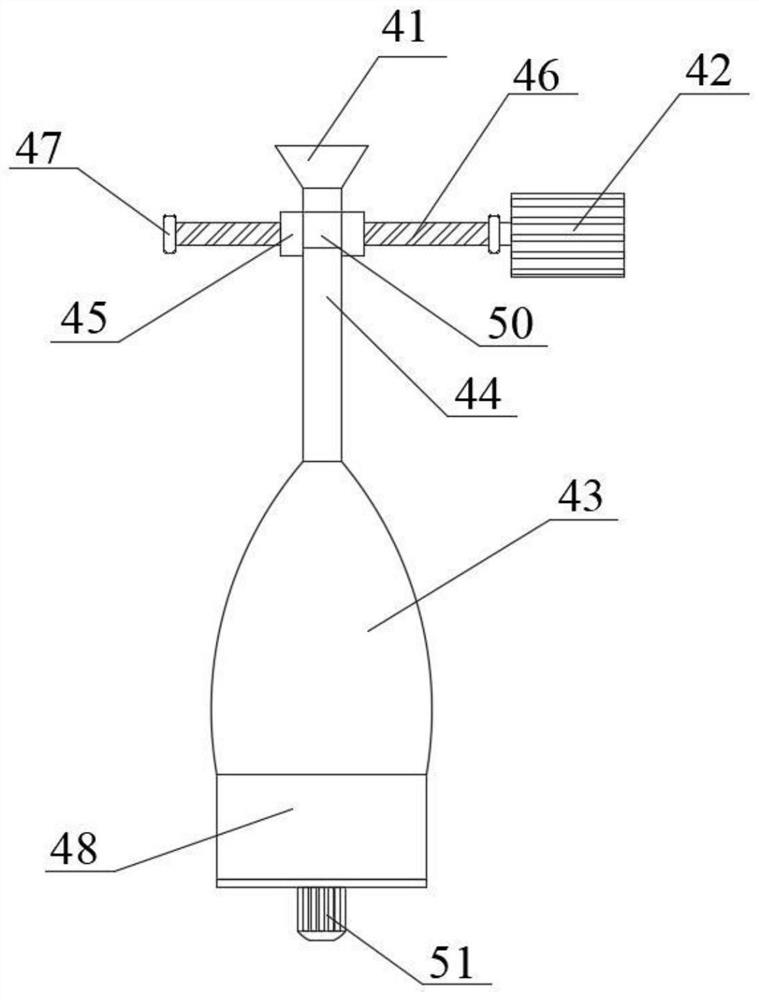

[0049] Such as Figure 1-4 As shown, the present embodiment provides a greening garden landscape pavement engineering paving construction device, which is used for cement mortar laying, cement mortar compaction and leveling, cobblestone laying, cobblestone compaction, cleaning and dust removal in the greening garden landscape pavement engineering paving construction process . Specifically, the pavement construction device for greening garden landscape pavement engineering includes an installation box 10, and the installation box 10 is provided with a cement mortar laying mechanism 20, a compacting and leveling mechanism 30, and a cobblestone laying mechanism 40. Wherein, cobblestone paving mechanism 40 comprises feed hopper 41, drive motor 42, storage tank 43, and feed hopper 41 is arranged on the top of installation box 10, and the bottom of feed hopper 41 passes through two feeding cavities 44 that are arranged symmetrically. Connected with the storage tank 43, the bottom c...

Embodiment 3

[0058] Such as figure 1 , Figure 8-9 As shown, the difference between the pavement construction device for greening garden landscape pavement engineering provided by the present embodiment and Embodiment 2 is that a cleaning and dust removal mechanism 60 is provided between the compaction leveling mechanism 30 and the cobblestone laying mechanism 40, and the cleaning and dust removal mechanism 60 includes Dust removal box 61 and cleaning head 62, dust removal box 61 is embedded in installation box 10, and the bottom of dust removal box 61 evenly distributes a plurality of cleaning heads 62, and the lower surface of cleaning head 62 is distributed with dense bristles 63. The inner chamber of the dust removal box 61 is provided with the second collection chamber 64, the blower chamber 65 and the first collection chamber 66 successively from top to bottom, and the top of the first collection chamber 66 is provided with the first filter screen 67, and the first collection chamber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com