Friction transmission rocker arm annular cooler

A technology of friction transmission and arm ring, which is applied in the field of mineral sintering equipment, can solve the problems of large labor cost investment, complex transmission device, relatively high processing and installation requirements, and achieve the effects of improving recovery, reducing running resistance, and preventing heat dissipation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to more clearly illustrate the technical solutions of the present invention, the accompanying drawings will be described below as required simply introduced Apparently, the accompanying drawings in the following description are only some embodiments of the present invention, those of ordinary skill person concerned, without creative efforts, can obtain other embodiments based on these drawings. To facilitate understanding of the invention, the accompanying drawings and the following specific embodiments of the present invention will be described in more detail.

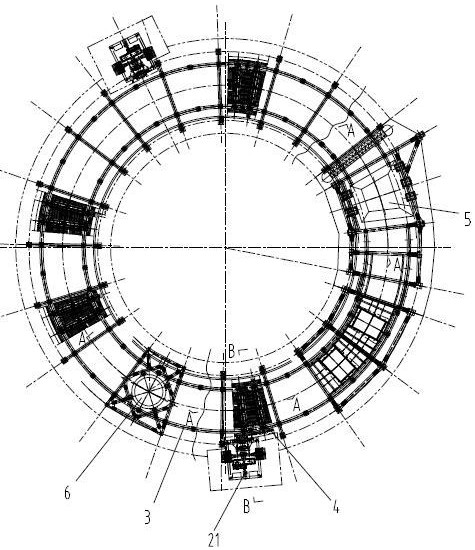

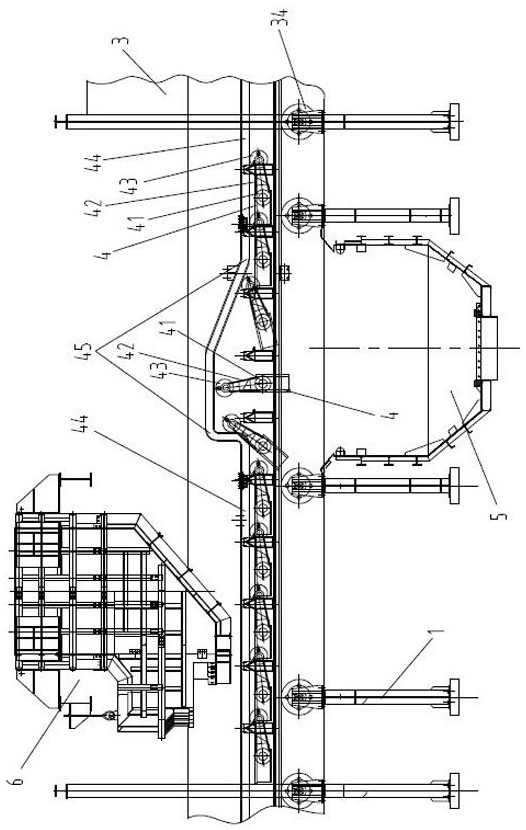

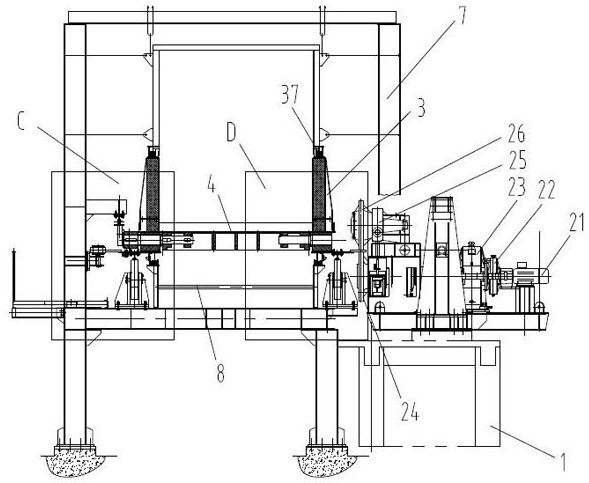

[0034] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Looking:

[0035] The new friction transmission shaken armband cold swing frame rack 1, each of the other components are installed, the combination of the carrier, connection of a new complete generally annular cooler 1 by the rotation of the frame.

[0036] Drive means comprises a motor 21, a motor 21 connected to a final drive and friction w...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap