Multifunctional glass moving and carrying device

A handling device and multi-functional technology, which is applied in the field of multi-functional glass moving and handling devices, can solve the problems of glass cracking, suction cups are not easy to touch the glass, and affect the firmness of the suction cups to absorb glass, so as to improve safety and prevent wrong handling. glass effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Next, the technical solutions in the embodiments of the present invention will be described in conjunction with the embodiment of the present invention. Based on the embodiments in the present invention, those of ordinary skill in the art will belong to the scope of the present invention without all other embodiments obtained in the preparation of creative labor.

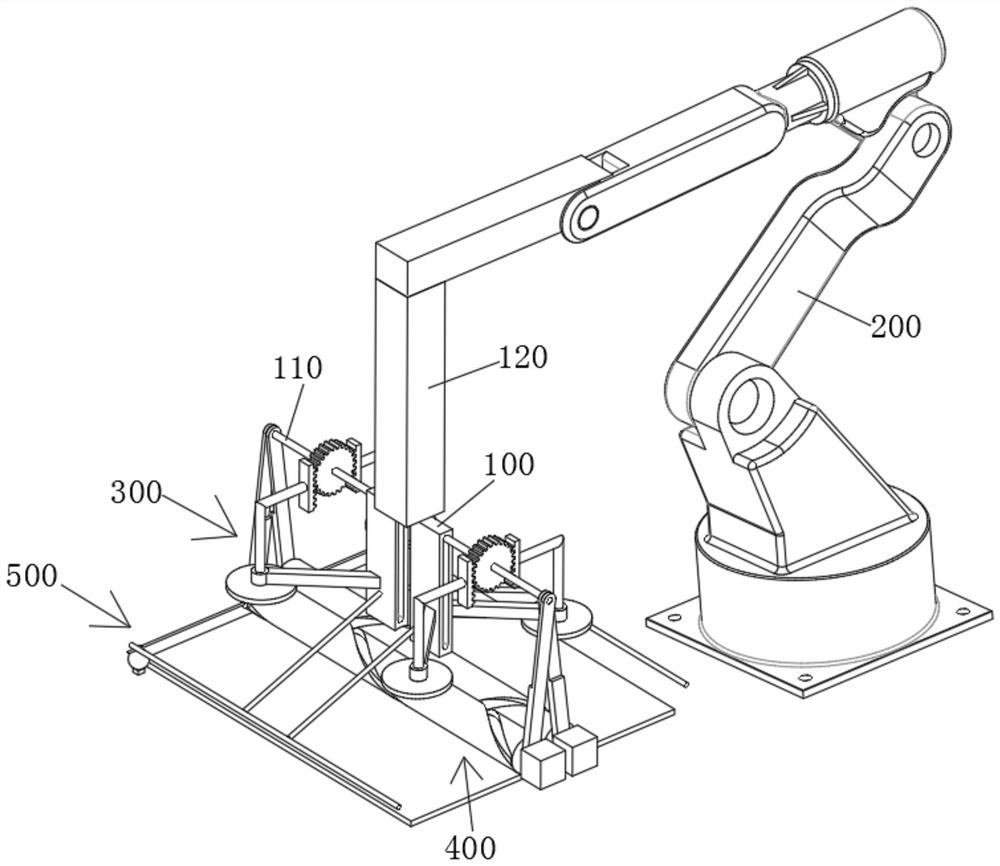

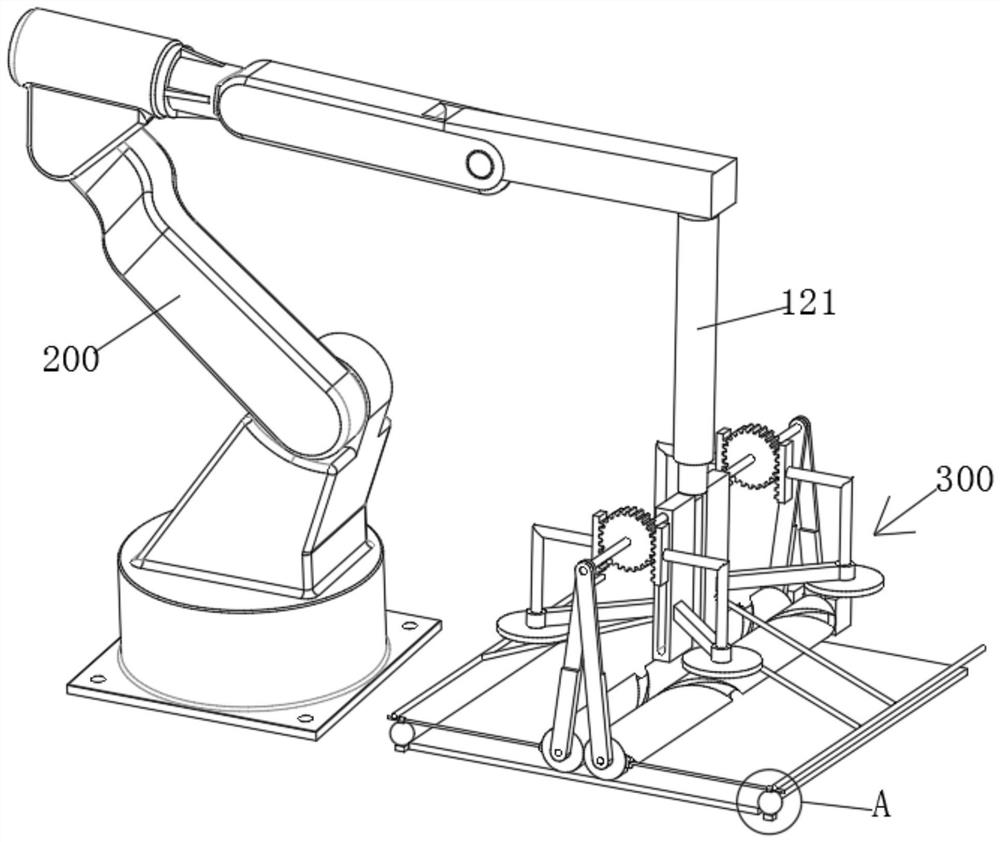

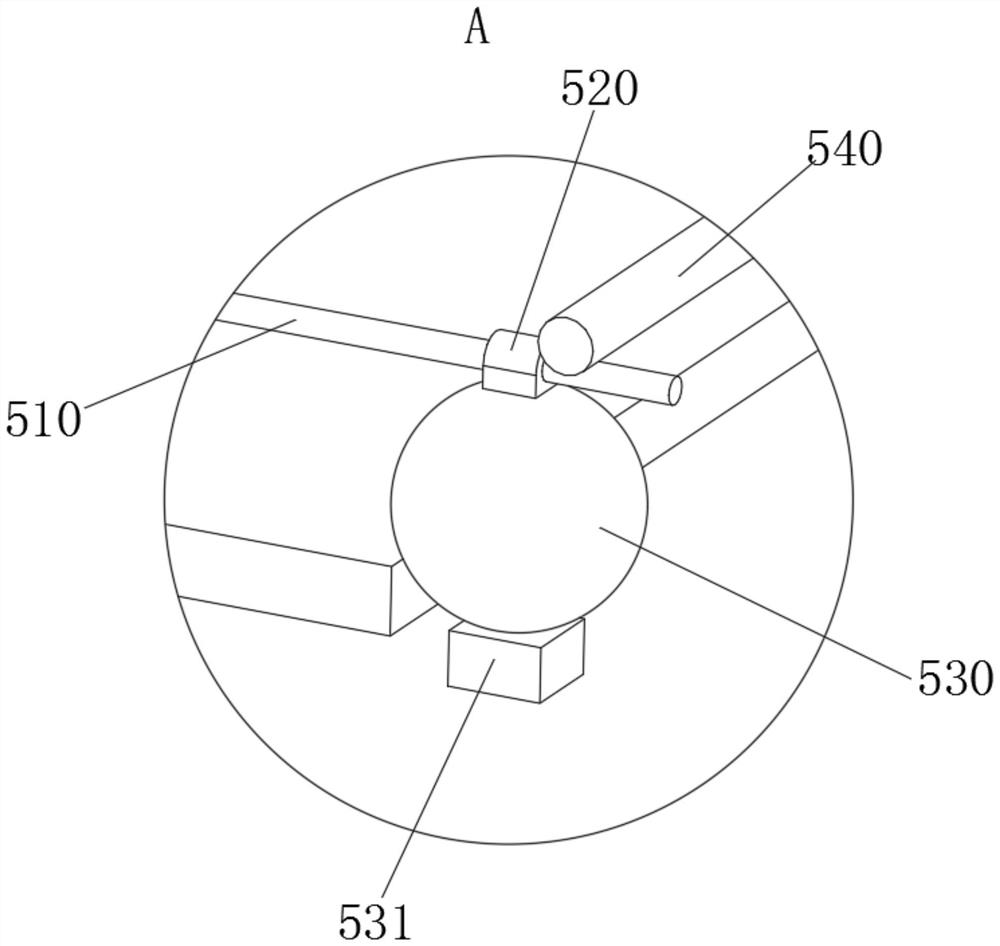

[0030] See Figure 1-9As shown, a multi-functional glass moving handling device includes two symmetrical distribution support column 100, and a rectangular vias are opened inside the support post 100, and the two rectangular vias are slidable against shaft 110, two The top portion of the support column 100 is fixedly connected to the drive case 120 that moves up and down, and the top of the transmission case 120 is fixedly connected to the robot 200, and both ends of the middle portion of the shaft 110 are provided with adsorbent mechanism 300 for adsorbing glass. The adsorption mechanism 300 includes a gear 310 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com