Cutter continuous automatic straightening and leveling machine and cutter continuous heat treatment furnace

A heat treatment furnace and automatic adjustment technology, applied in heat treatment furnaces, heat treatment equipment, cutting tools, etc., can solve the problems of high temperature and low work efficiency in heat treatment furnaces, achieve good deformation quality, improve production efficiency, and save manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

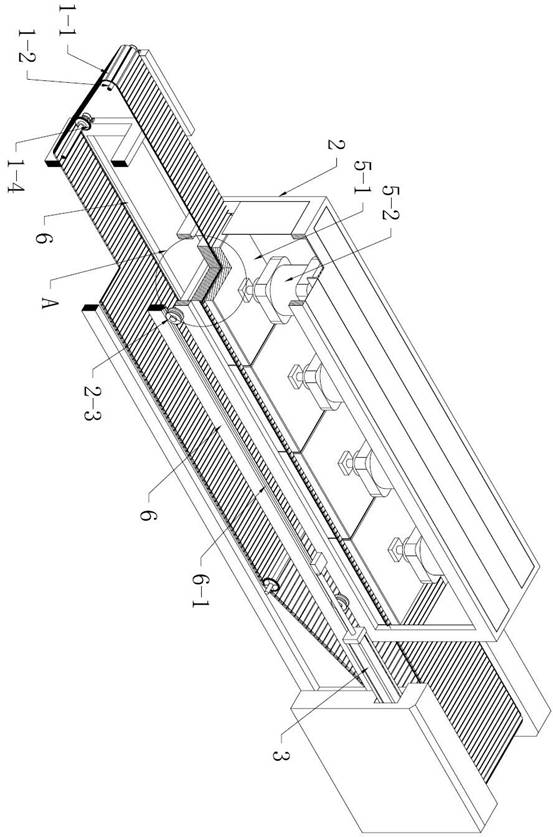

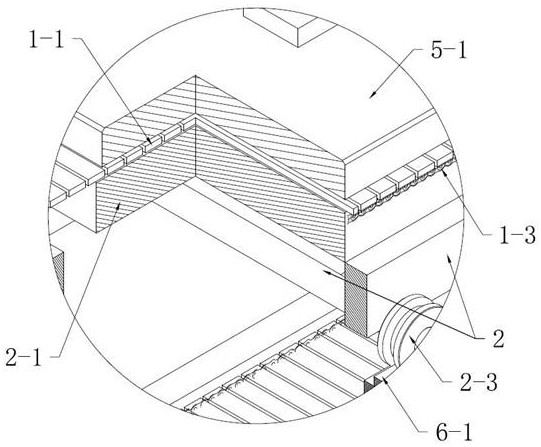

[0053] refer to Figures 1 to 3, the tool continuous automatic straightening and leveling machine of the present embodiment includes a conveyor 1, a mobile vehicle 2, a mobile drive unit 3, a base plate 2-1 and a flattening and straightening device 5, and the flattening and straightening device 5 includes a pressing plate 5 -1 and the lifting drive device 5-2, the lifting drive device 5-2 is installed on the mobile car 2, and the lifting drive device 5-2 can drive the pressing plate 5-1 to rise or fall, and the conveyor belt of the conveyor 1 is used for automatic conveying of tools The blade is also partially positioned above the base plate 2-1 of the mobile vehicle 2. When the pressing plate 5-1 was pressed down, the base plate 2-1 of the mobile car 2 could play a supporting role and forcibly constrain the cutter blade to be straightened and straightened, and also prolong the service life of the conveyor belt.

[0054] In this embodiment, the flattening and straightening de...

Embodiment 2

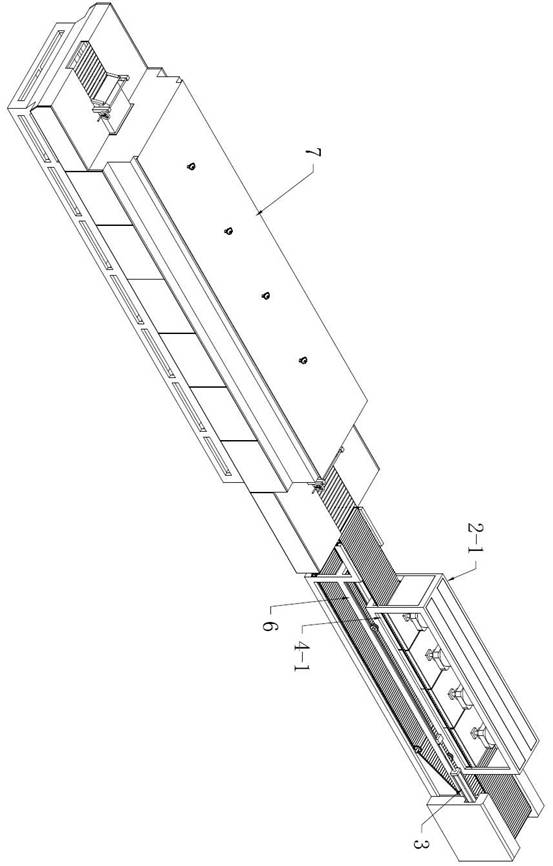

[0063] The main technical solutions of this embodiment are basically the same as those of Embodiment 1 or Embodiment 2, and the features not explained in this embodiment are explained in Embodiment 1 or Embodiment 2, and will not be repeated here. The number of flattening and straightening devices 5 in this embodiment is set in multiples, and the multiple flattening and straightening devices 5 are sequentially installed on the mobile vehicle 2 from the feeding direction to the discharging direction.

Embodiment 3

[0065] The main technical solution of this embodiment is basically the same as that of the above embodiment, and the features not explained in this embodiment are explained in the above embodiment, and will not be repeated here. In this embodiment, the tool continuous automatic straightening and leveling machine 7 of this embodiment is provided with a digital controller, and the digital controller controls the cooperative operation of the conveyor 1, the mobile drive device 3 and the flattening and straightening device 5, with a high degree of automation , strong flexibility.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com