Wrench and device for intelligent precise adjustment of ballastless track slab

A ballastless track, intelligent technology, applied in track, track laying, track maintenance, etc., can solve the problems that affect the working efficiency of the regulating device, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

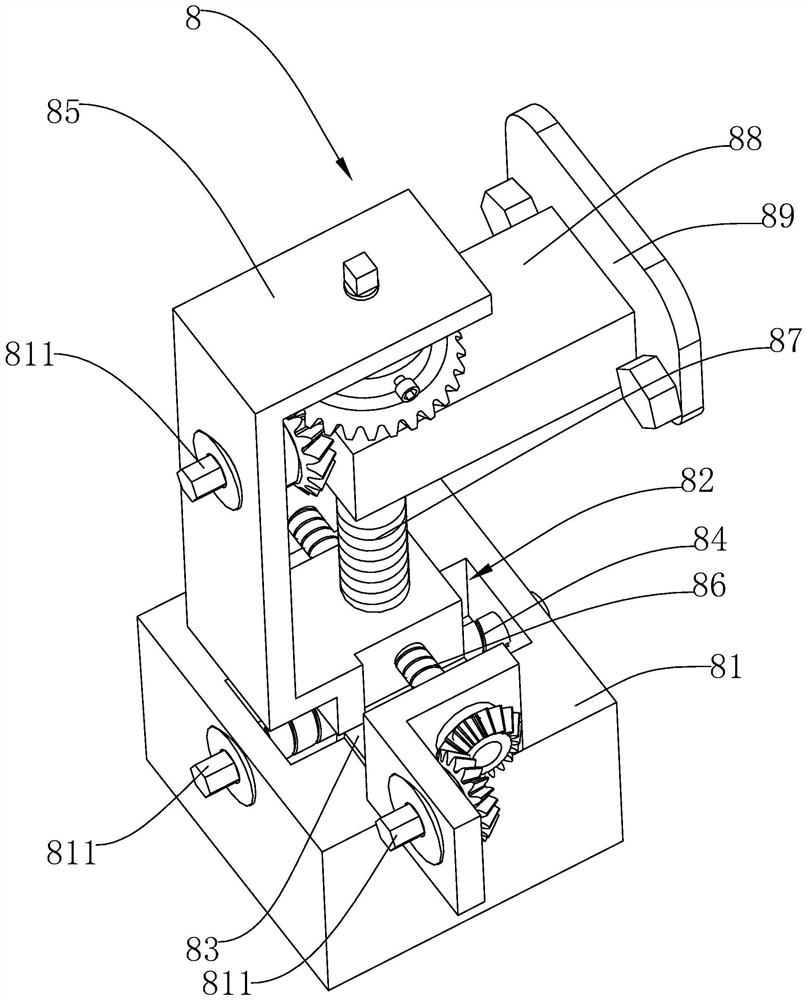

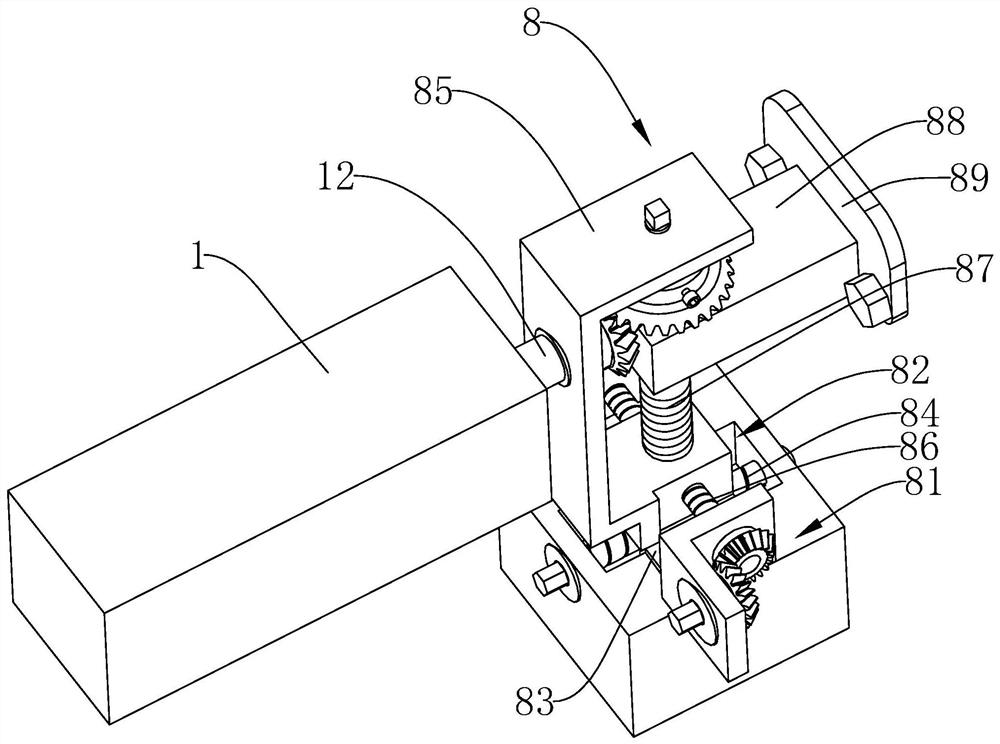

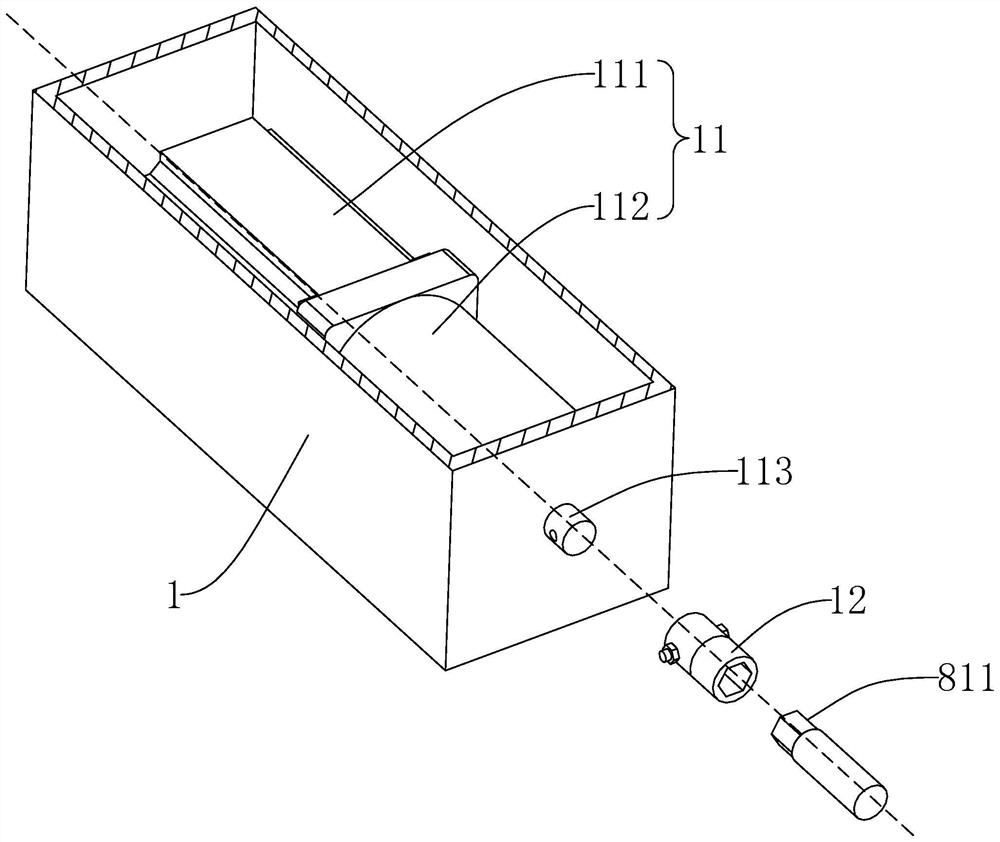

[0057] Such as figure 2 and image 3 As shown, a ballastless track slab intelligent precision wrench includes a box body 1, and a drive device 11 is installed in the box body 1. The drive device 11 includes a servo motor 111 fixedly installed in the box body 1 and a servo motor 111 fixedly installed in the box body. The reducer 112 in 1, the reducer 112 and the servo motor 111 are coaxially connected; the drive end of the reducer 112 is fixedly connected with the rotating shaft 113, and the rotating shaft 113 extends out of the box body 1 and is connected to the box body 1 in rotation, and the rotating shaft 113 passes through the The bolt is fixedly connected with a sleeve 12 .

[0058] Such as figure 2 and image 3 As shown, the outer wall of the sleeve 12 in this embodiment is a circumferential surface, and the inner peripheral wall of the sleeve 12 along its rotational circumference includes at least one plane. The inner peripheral wall of the sleeve 12 in this embodi...

Embodiment 2

[0067] Such as Figure 7 and Figure 9 As shown, a smart precision wrench for a ballastless track slab, the sleeve 12 and the driving end of the reducer 112 are detachably connected through a connecting piece 5, and the connecting piece 5 in this embodiment includes a connecting block 51, a pushing block 52 and an abutment Block 53, the driving end of the reducer 112 is welded with a connecting shaft 54, the connecting shaft 54 extends out of the box body 1 and is connected to the box body 1 in rotation, and one end of the connecting shaft 54 extending out of the box body 1 is inserted into the sleeve 12 and connected with the sleeve 12, the inner peripheral wall abuts, and the end wall of the connecting shaft 54 away from the reducer 112 is provided with a feed groove 541, and the outer peripheral wall of the connecting shaft 54 is provided with a through groove 542. There are two through grooves 542 in this embodiment and Both communicate with the feed slot 541 , an...

Embodiment 3

[0071] Such as Figure 10 and Figure 11 As shown, an intelligent fine-tuning device for a ballastless track slab, each connecting frame 23 is rotatably connected to two feed screw rods 6, the first mechanical arm 24 and the feed screw rods 6 are arranged in one-to-one correspondence, and the same connecting frame 23 The axes of the two feed screw rods 6 are collinear, and all the feed screw rods 6 are axially in the same direction. The end of the first mechanical arm 24 away from the box body 1 is fixedly connected with a drive screw block 61, and the drive screw block 61 is slidably connected to the connecting frame 23 along the axial direction of the feed screw rod 6, and the drive screw block 61 and the corresponding feed screw rod 6 threaded connection; the drive assembly 7 that drives the feed screw 6 to rotate is installed on the connecting frame 23, and the drive assembly 7 and the feed screw 6 are arranged in one-to-one correspondence.

[0072] Such as Figure 11 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com