water saving valve

A valve and valve body technology, applied in the field of water-saving valves, can solve problems such as inability to accurately meet production and living needs, adjustment of flow channels that cannot flow, water pressure, and low ability to adjust water flow, so as to avoid excessive injection water pressure. Large, ensure water safety, and avoid water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

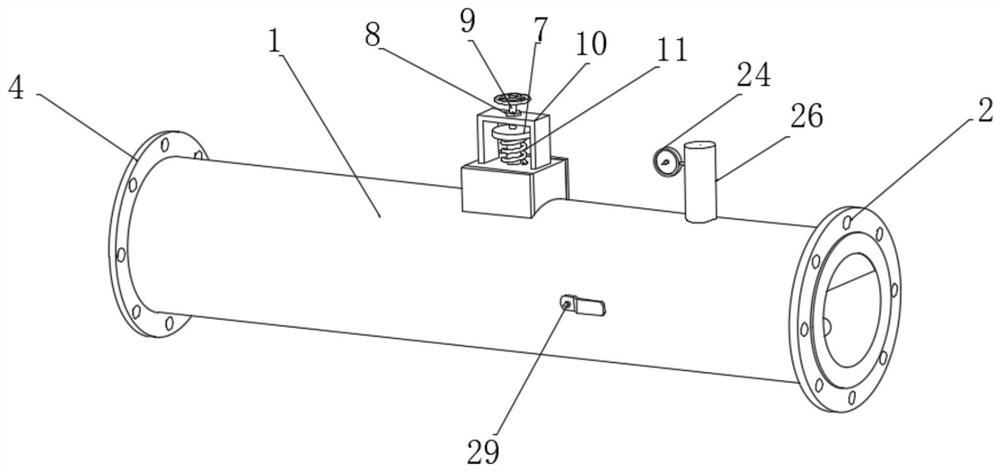

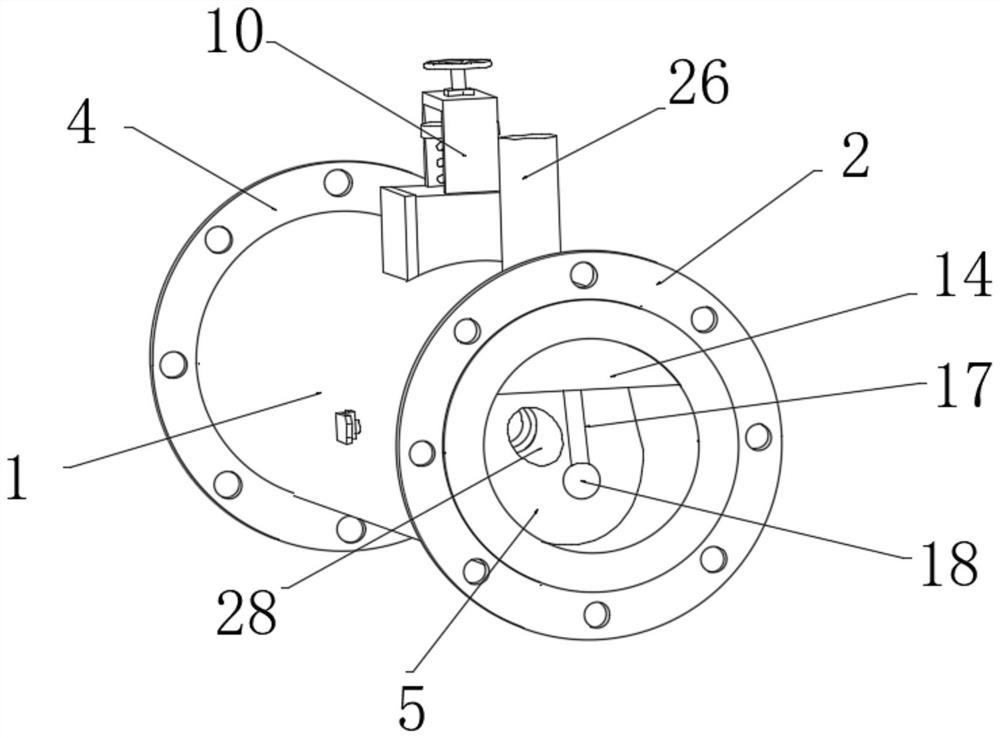

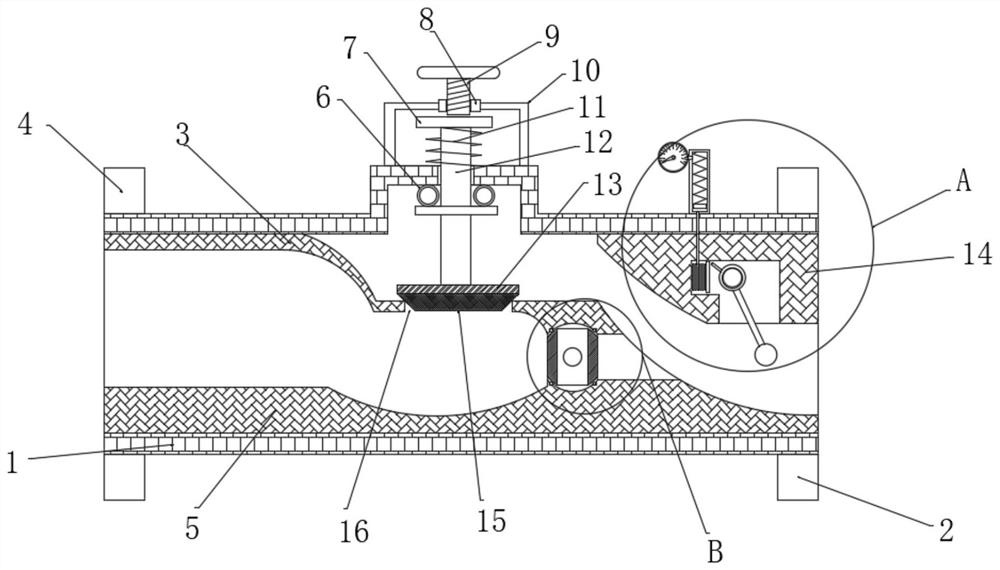

[0032] like Figure 1 to Figure 7 As shown, a water-saving valve according to the present invention includes a valve body 1, a first flange 2 and a second flange 4, and the two ends of the valve body 1 are respectively installed with a first flange 2 and a second flange 4; the two ends of the valve body 1 are respectively installed with the first flange 2 and the second flange 4, the inner wall of the valve body 1 is correspondingly installed with the first limit block 3 and the second limit block 5, the first limit A gap 16 is formed between the block 3 and the second limit block 5. A transfer groove 31 is opened inside the second limit block 5, and a transfer ball 32 is installed in the inside of the transfer groove 31 through the rotating shaft 29. The inside of the transfer ball 32 A diversion hole 30 is provided, an annular groove is formed on the groove wall of the transfer groove 31, and a sealing ring 33 is arranged inside the annular groove. The sealing ring 33 is tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com