Power assembled battery pack of electric vehicle

A technology for combining batteries and electric vehicles, applied in battery pack parts, circuits, electrical components, etc., can solve problems such as rapid product update and waste of resources unfavorable for car companies, and achieve the effect of stable voltage and current and reducing dependence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

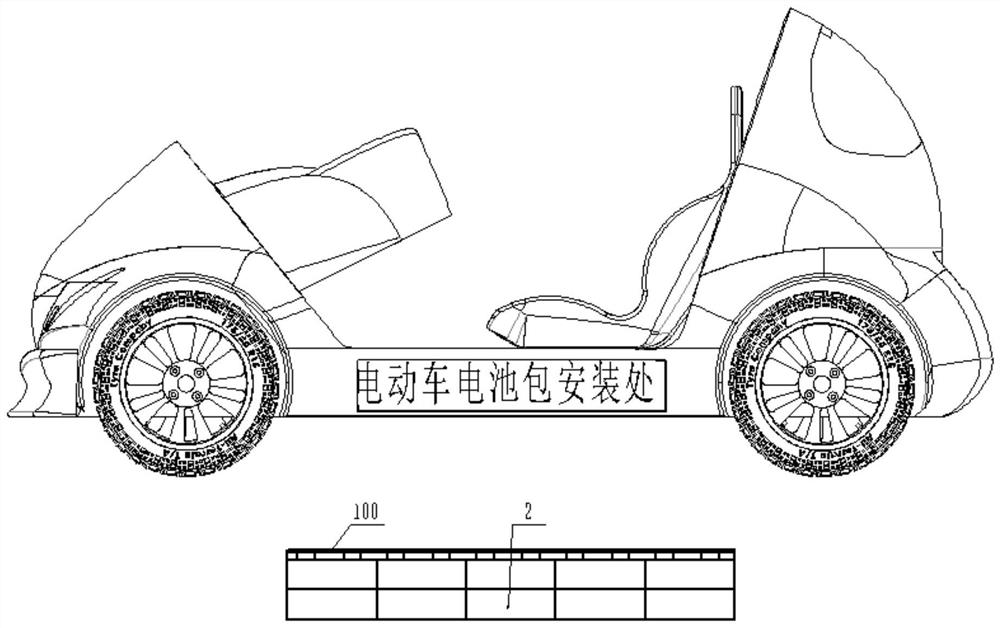

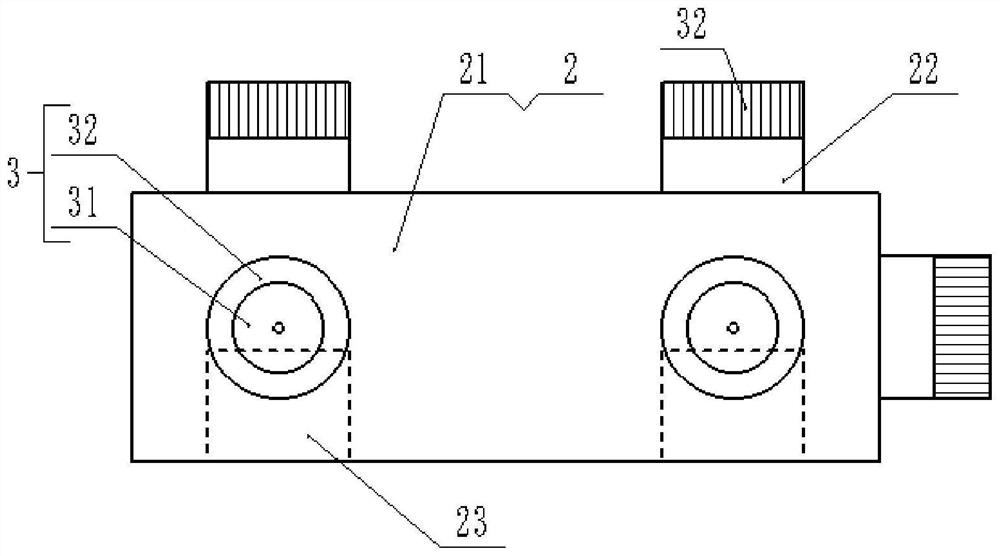

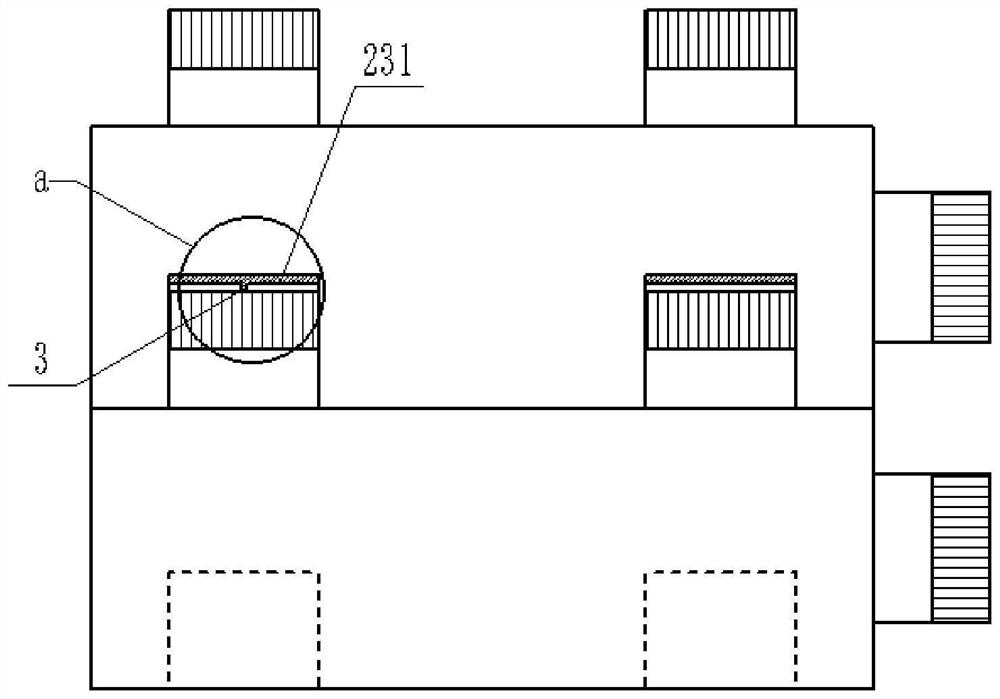

[0032] like Figure 1-7 As shown, the electric vehicle power combination battery pack 2 provided in this embodiment can add a pack of power batteries, and can be used in different vehicle models to improve application scenarios. An electric vehicle power combined battery pack 2, comprising: a power battery 1; at least one battery pack 2, the power battery 1 is detachably installed in the battery pack 2, and the battery pack 2 has a housing 21, a protruding The connecting shaft 22 and the recessed connecting hole 23; and the protruding connecting shaft 22 is provided on the housing 21 in more than one place, and the recessed connecting hole 23 is provided in the housing 21 in more than one place; wherein, the The protruding connecting shaft 22 is detachably and fixedly installed in the concave connecting hole 23; the concave connecting hole 23 has a fixed electrode 231; the fixed electrode 231 is electrically connected to the power battery 1; and the movable electrical connecto...

Embodiment 2

[0035] like Figure 1-7 As shown, in this embodiment, in order to install the power battery 1 in the battery pack 2 for further convenience, the housing 21 also has a battery storage box 211, and the power battery 1 is detachably installed in the battery storage box 211 in. In practical application, the battery storage box 211 ensures the effective fixation of the power battery 1 and reduces the phenomenon of loosening during use. Of course, it also includes a protective cover, which can be detachably installed on the battery storage box 211 to protect the power battery 1 and prevent it from popping up during use.

[0036] At the same time, in order to ensure the external power supply of the battery storage box 211, one end of the battery storage box 211 is electrically connected to the fixed electrode 231, and the other end of the battery storage box 211 is electrically connected to the contact electrode 31; Specifically, after the power battery 1 is put into the battery st...

Embodiment 3

[0038] like Figure 1-7 As shown, in this embodiment, in order to realize the stability of multiple battery packs 2 during the connection process, the diameter of the protruding connection shaft 22 is the same as that of the concave connection hole 23 . In actual use, the constraints here are limited, and its design also effectively refers to Lego bricks, so that in the actual splicing and assembly process, the installation process is greatly reduced, and there is no need to add other accessories. Of course, in order to further ensure stability, after the combination of multiple battery packs 2 is completed, a fixed housing 100 is installed outside the assembled battery pack 2, which is made of industrial plastic and has low production cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com