Tobacco characteristic aroma component and preparation method and application thereof

A technology of aromatizing ingredients and dry tobacco, which is applied in the field of tobacco, can solve the problem of less aromatizing ingredients, and achieve the effects of improving aroma, improving quality, and being easy to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

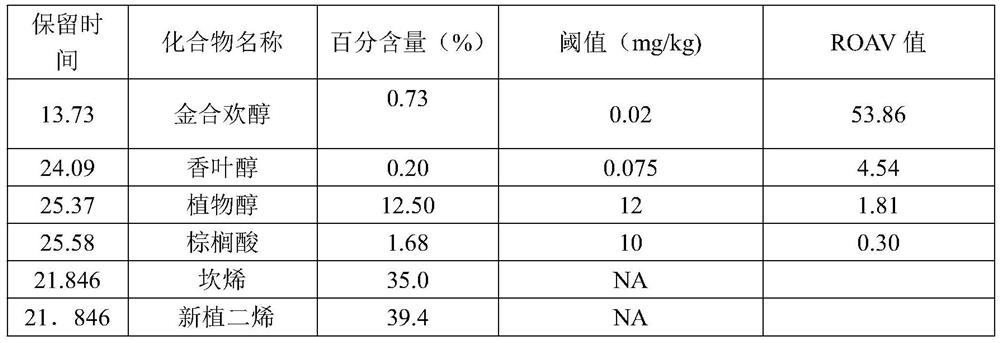

Embodiment 1

[0023] (1) Soak 50g of tobacco leaves in 95% ethanol for 2 hours, the ratio of solid to liquid is 1:10, extract in a water bath under reflux, the temperature of the water bath is 50°C, repeat the extraction twice, and then carry out vacuum distillation at 50°C to concentrate the extracted solution to brown Brown viscous liquid, 8.7 grams of extract was obtained after cooling.

[0024] (2) Dissolve the above-mentioned extract in water, filter it, and put it on a macroporous adsorption resin column HPD-100. The dosage is 20 times the mass of the extract. With a flow rate of 1.5BV / h, first wash 10 column volumes with water, and then 20 column volumes were eluted with 95% ethanol, and the eluate was collected, and the target segment I was concentrated under reduced pressure to 5.9 g

[0025] (3) After the target segment I is dissolved and filtered with ethanol, go to the gel chromatography column (filler is SephadexLH-20, and the consumption is 40 times of the target segment I qua...

Embodiment 2

[0044] (1) Soak 50 g of tobacco leaves in 95% ethanol for 2 hours, the ratio of solid to liquid is 1:8, and extract in a water bath under reflux at a temperature of 60° C., and repeat the extraction twice. Afterwards, the extracted solution was concentrated by distillation under reduced pressure at 50° C. to a brown viscous liquid, and 9.5 grams of extract was obtained after cooling.

[0045] (2) Dissolve the above-mentioned extract in water, filter it, put it on a macroporous adsorption resin column (HPD-100, the dosage is 10 times the mass of the extract), and elute 8 columns with water at a flow rate of 1.5BV / h volume, then 20 column volumes were eluted with 90% ethanol, and the eluate was collected, and the target segment I was concentrated under reduced pressure to 6.6g

[0046] (3) After the target segment I is dissolved and filtered with ethanol, the gel chromatographic column packing is (SephadexLH-20, the dosage is 30 times the mass of the target segment I), and the m...

Embodiment 3

[0051] (1) Soak 50g of tobacco leaves in 95% ethanol for 1h, the ratio of solid to liquid is 1:20, extract in a water bath under reflux, and the temperature of the water bath is 70°C, repeat the extraction twice, and then carry out vacuum distillation at 50°C to concentrate the extracted solution to brown Brown viscous liquid, 10.3 grams of extract was obtained after cooling.

[0052] (2) Dissolve the above-mentioned extract in water, filter it, put it on a macroporous adsorption resin column (HPD-100, the dosage is 15 times the mass of the extract), and elute 8 columns with water at a flow rate of 1.5BV / h volume, then 15 column volumes were eluted with 95% ethanol, and the eluate was collected, and the target segment I was concentrated under reduced pressure to 7.3g

[0053] (3) After dissolving and filtering the target segment I with ethanol, put it on a gel chromatographic column (SephadexLH-20, the dosage is 50 times the mass of the target segment I), the mobile phase is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com