Plastic uptake device

A component and hoarding technology, which is applied in the field of plastic-absorbing equipment, can solve problems such as unstable quality, uneven sheet thickness, and uncoordinated temperature, so as to improve thermal efficiency and thermal energy utilization, improve product quality stability, and accelerate cooling speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following is further described in detail through specific implementation methods:

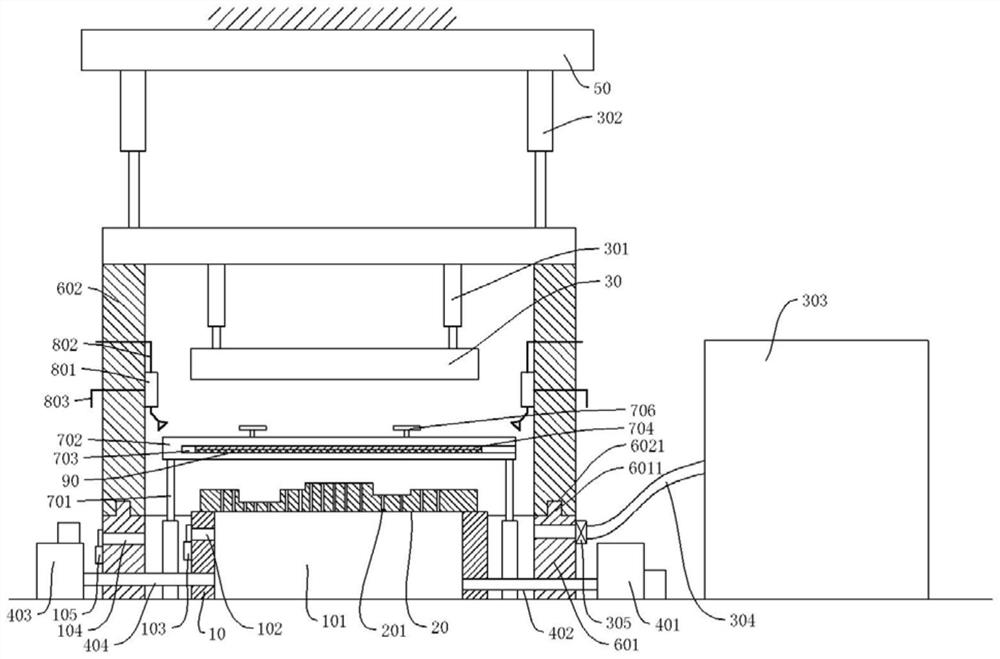

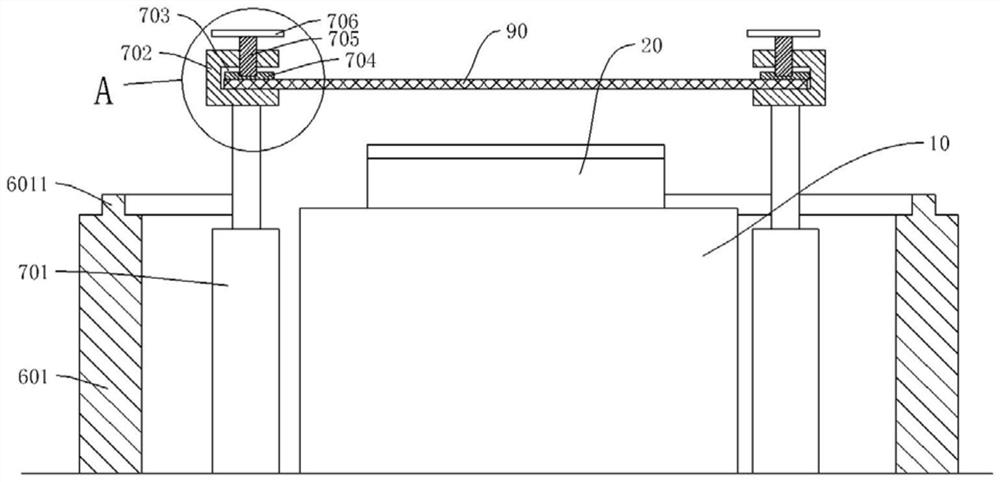

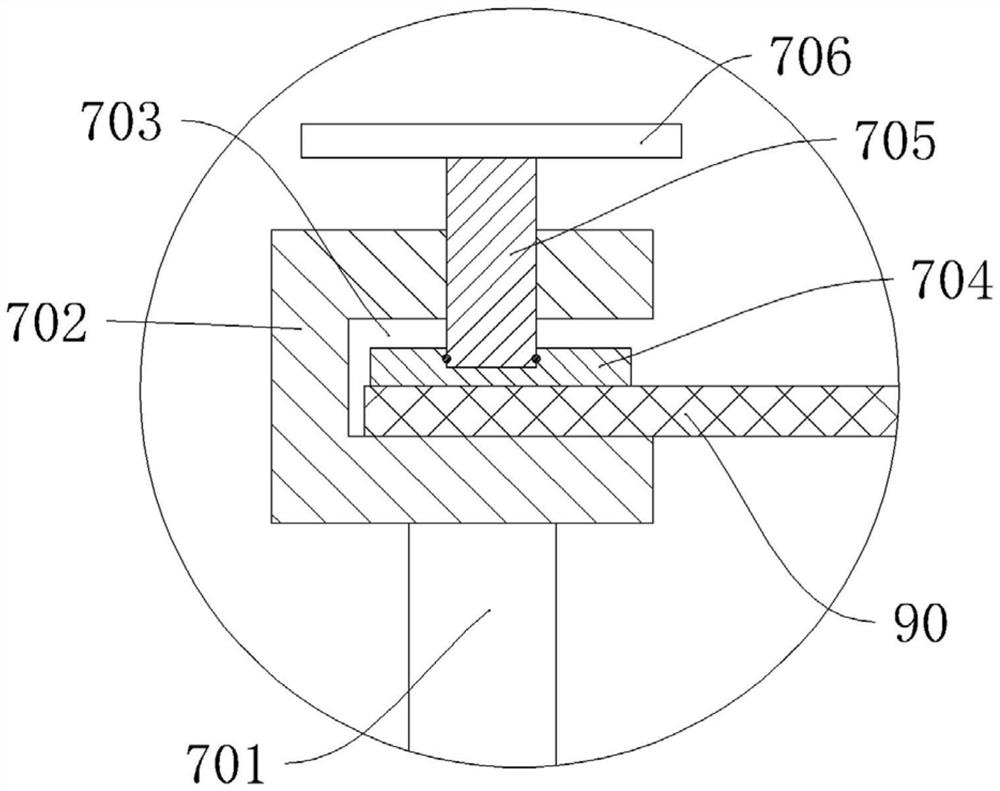

[0032] The reference signs in the drawings of the description include: support 10, cavity 101, first air inlet 102, first electromagnetic valve 103, second air inlet 104, second electromagnetic valve 105, lower mold base 20, suction Plastic hole 201, heating plate 30, first air cylinder 301, second air cylinder 302, preheating chamber 303, third air pipe 304, first one-way valve 305, hot air blower 401, first air pipe 402, vacuum machine 403, the first Two air pipes 404, frame 50, lower panel 601, sealing bump 6011, upper panel 602, sealing groove 6021, electric telescopic rod 701, horizontal plate 702, rectangular slot 703, pressure plate 704, screw rod 705, handle 706, Venturi Inside pipe 801, first pipe 802, second pipe 803, plastic sheet 90.

[0033] A blister device such as Figure 1-Figure 3 As shown, it includes an upper enclosure 602 , a lower enclosure 601 , a support 10 a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap