Wrapping rod group used for aviation data bus to improve film wrapping accuracy

An aviation data bus and wrapping technology, which is applied in the direction of conductor/cable insulation, etc., can solve the problems of increasing the outer diameter of the insulation and increasing the dielectric constant index of the insulation, so as to achieve a small dielectric constant, realize high-precision processing, reduce The effect of wrapping angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

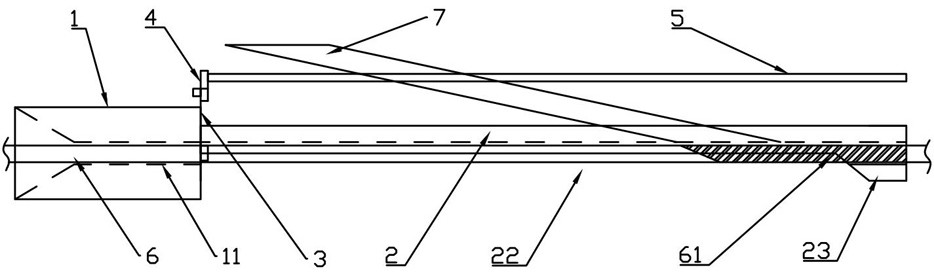

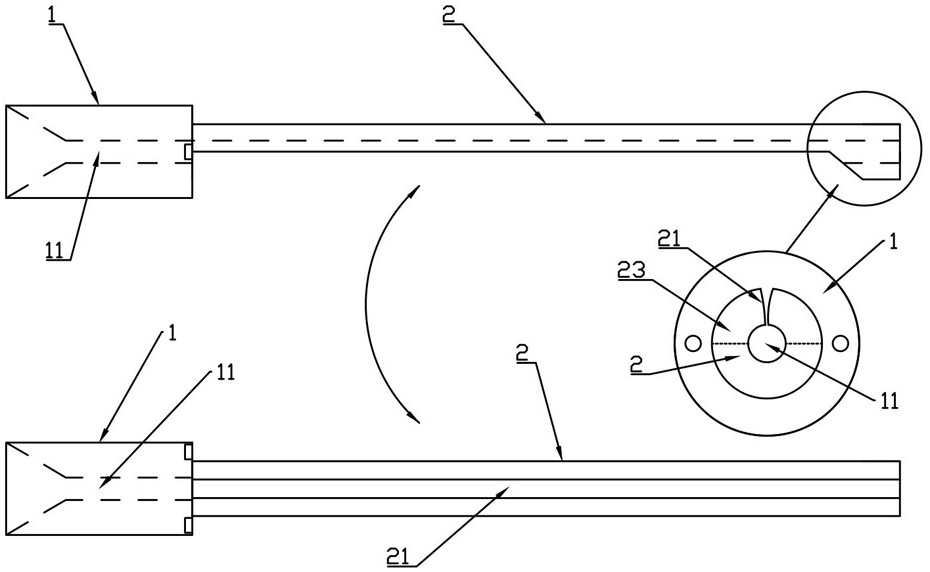

[0027] The wire insulation in the 1394B data bus with 24AWG wire gauge is wrapped, and the insulating medium is required to be wrapped with microporous polytetrafluoroethylene film and wrapped with polytetrafluoroethylene raw material tape. After sintering, the dielectric constant is 1.5 to 1.55. After the process is processed, the outer diameter of the wire will be reduced by about 30% during sintering. When the outer diameter reaches the specified value after sintering, the dielectric constant is 1.7-1.75; with the wrapping rod set of the present invention, the wrapping angle is reduced to 15° , The outer diameter of the wire becomes smaller by about 10% during sintering, and the dielectric constant meets the requirements. The specific operation is as follows:

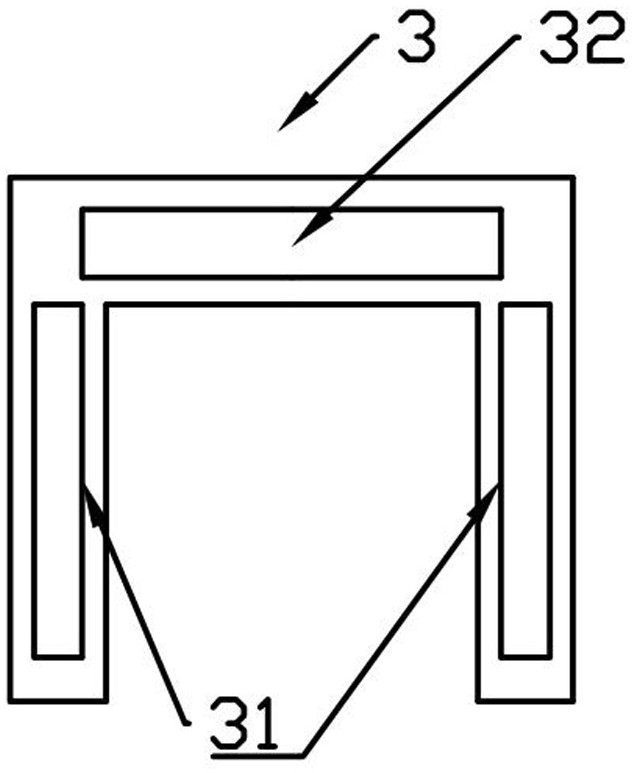

[0028](1) The selected length of the wrapping rod group is 400mm, and the size of the wire hole is 1.5mm. Set the density to 0.7g / cm 3 , the polytetrafluoroethylene microporous membrane with a width of 7mm is insta...

Embodiment 2

[0035] (1) The selected length of the wrapping rod group is 500mm, and the size of the wire hole is 2mm. Install the polytetrafluoroethylene raw material tape with a density of 1.6 and a width of 6mm on the wrapping head of the wrapping machine, and pull out the core wire with an outer diameter of 1.40mm wrapped around the microporous tape from the discharge end of the wrapping machine. Pass through the wire hole of the wrapping head and the wire hole of the wrapping rod group, install the metal inner conductor on the traction wheel, and finally connect it to the take-up reel.

[0036] (2) Install the wrapping rod set on the wrapping head of the wrapping machine and fix it. Lead out the PTFE raw material tape, pass through the thread guide wheel on the wrapping head, pass through the threading hole in the wrapping rod group, wind around the inner core wire for several turns, and fix it on the core wire.

[0037] (3) Pass the shaping guide rod through the first threaded hole a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com