Oil-filled watertight connecting device and equipment

A connecting device and watertight technology, applied in the field of electrical conduction, can solve problems such as damage to the outer sheath, and achieve the effects of avoiding damage to insulation, low cost and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

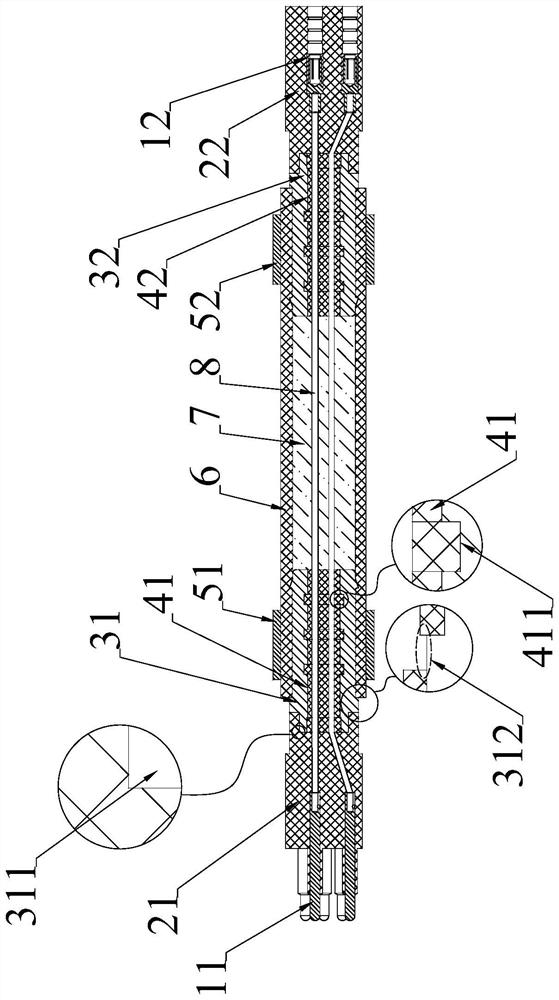

[0039] According to one embodiment of the present invention, the first connection assembly includes a first support 41 and a first housing 31 , the peripheral side of the first support 41 is provided with raised lines 411 , and the wire 8 runs through the inside of the first support 41 , the first housing 31 is sheathed on the peripheral side of the first supporting member 41 , and the first housing 31 is connected to the pipe member 6 .

[0040] The peripheral side of the first supporting member 41 is connected with the inner side of the first housing 31 by setting the embossing 411. The embossing 411 increases the contact area between the first supporting member 41 and the first housing 31, and at the same time The movement of the support member 41 along the axial direction of the first housing 31 acts as a limiter, which improves the fixing effect of the first support member 41 on the position of the wire 8 , thereby improving the tensile capacity of the wire 8 .

[0041] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com