Visual motor end cover

A technology of motor end caps and end caps, which is applied to electrical components, electromechanical devices, electric components, etc., can solve the problem that the opaque shell cannot understand the running status of the internal components of the motor in real time, etc., and achieve the effect of easy understanding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

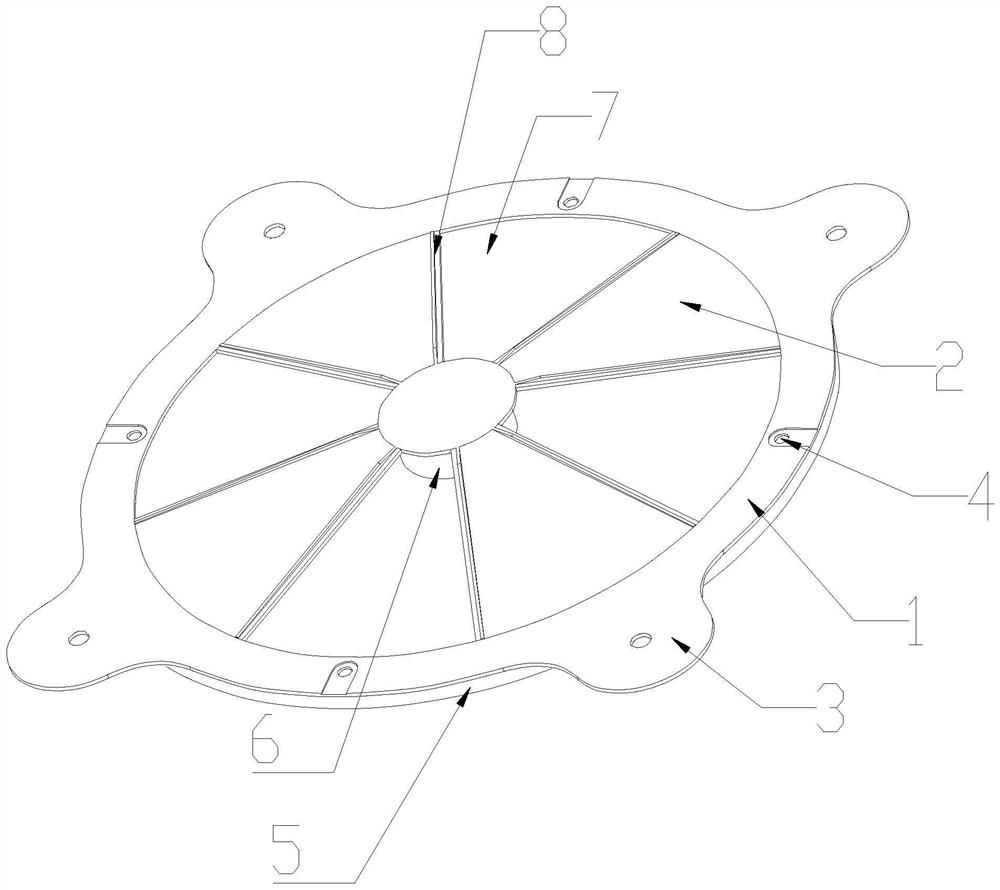

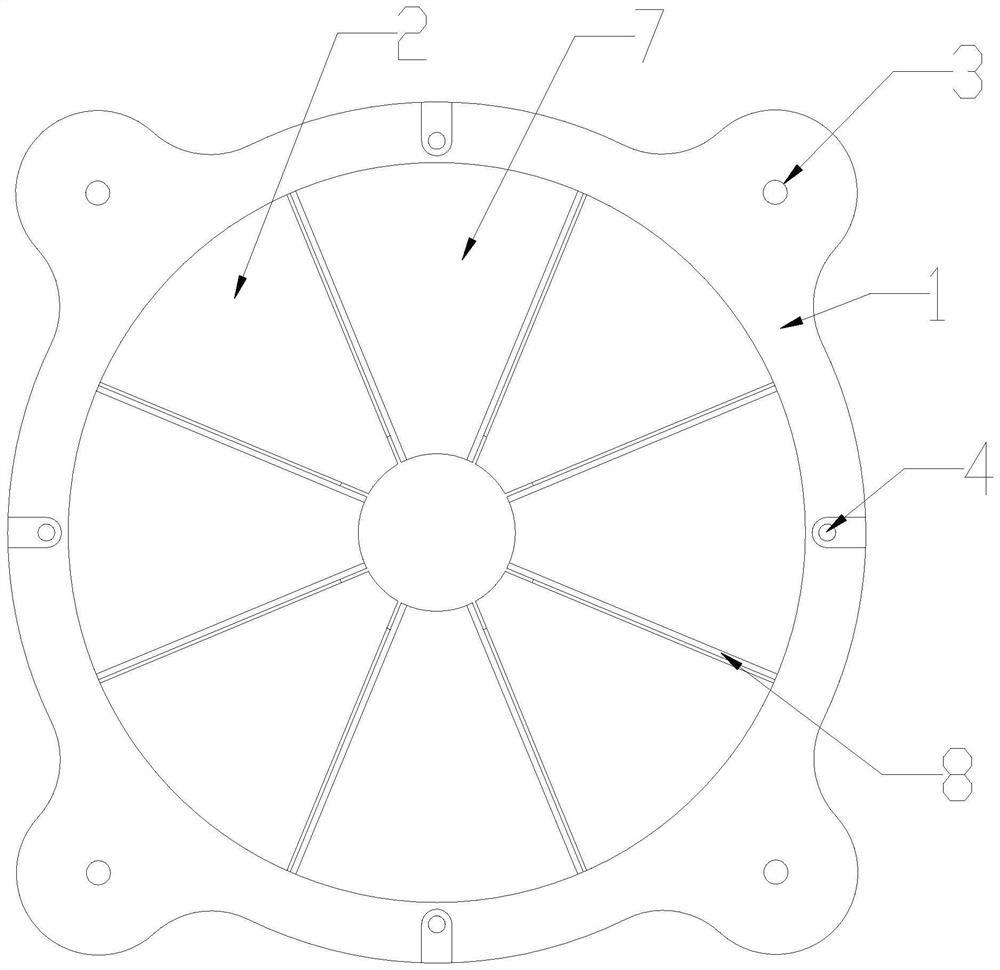

[0023] A kind of visual motor end cover of this embodiment, such as Figure 1-3 As shown, including the end cover main body 1, the end cover main body 1 is provided with multiple sets of mounting holes 4, the inner edge of the end cover main body 1 is provided with a connecting flange 5, the inner side of the end cover main body 1 is provided with a bearing sleeve 6, and the end cover main body 1 is provided with a bearing sleeve 6. The end face of the cover main body 1 is provided with multiple sets of visible window grooves 7 at intervals, and the end cover main body 1 is divided into multiple sets of connecting plates 2 by the visible window grooves 7, and the edges of the bearing sleeve 6 and the end cover main body 1 are connected through the connecting plates 2. A group of visible window slots 7 are sealed and fixed with a group of transparent cover plates.

[0024] Wherein, the inner edge of the end cover main body 1 is provided with a circle of protruding ring strips 9...

Embodiment 2

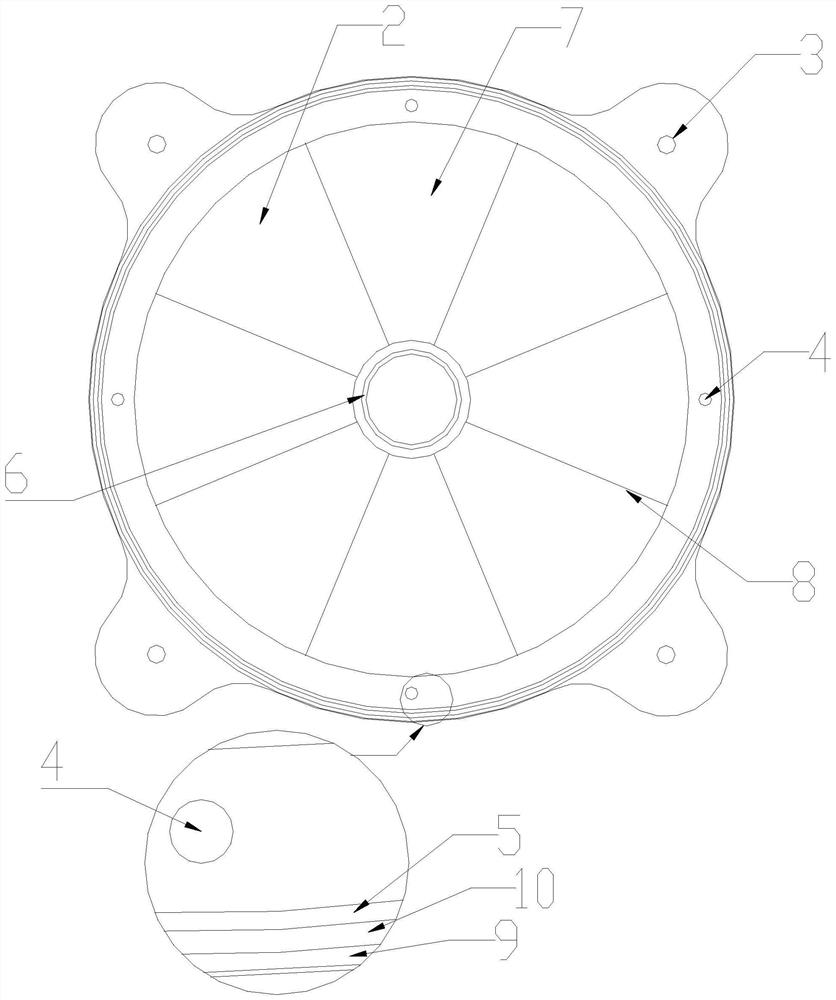

[0031] A kind of visual motor end cover of this embodiment, such as Figure 4-6 As shown, the main structure is the same as that of Embodiment 1, and the difference is that the visible window slot 7 is an irregular sector with the same shape, and the visible window slot 7 has two arc-shaped sides and two radial sides. The diameter of the visible window slot 7 is The lengths to the sides are not equal, the radial sides of the visible window slot 7 are inclined in the same direction, the direction of inclination of the radial sides is the same as the direction of rotation of the motor, and the direction of rotation of the inclined radial sides is the same as that of the motor, that is, when the motor is running The direction of the formed air duct is the same, the wind resistance formed by the end cover is also smaller, and the wind noise is also smaller.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com