A Teaching Model of Intelligent Biogas Reactor

A technology of teaching model and reactor, applied in the field of teaching model, can solve problems such as single structure and narrow knowledge range, achieve the effect of solving poor airtightness, and is conducive to experimental research and engineering popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

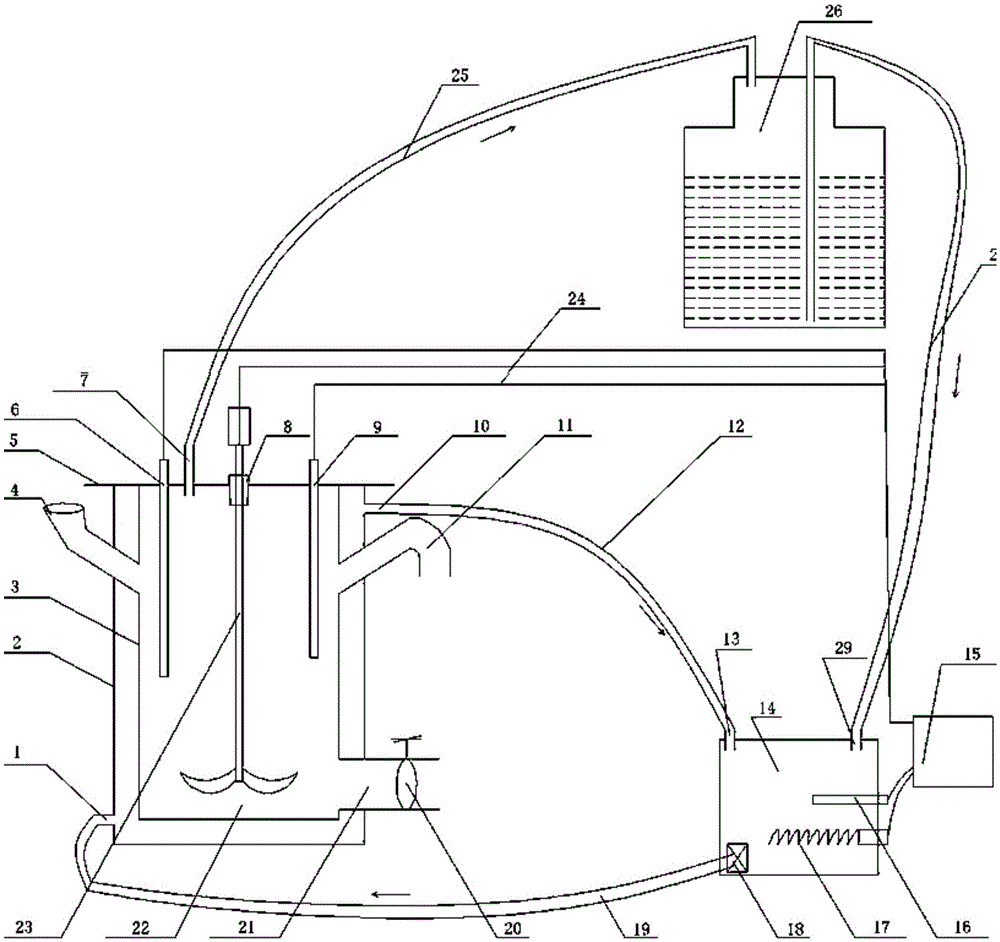

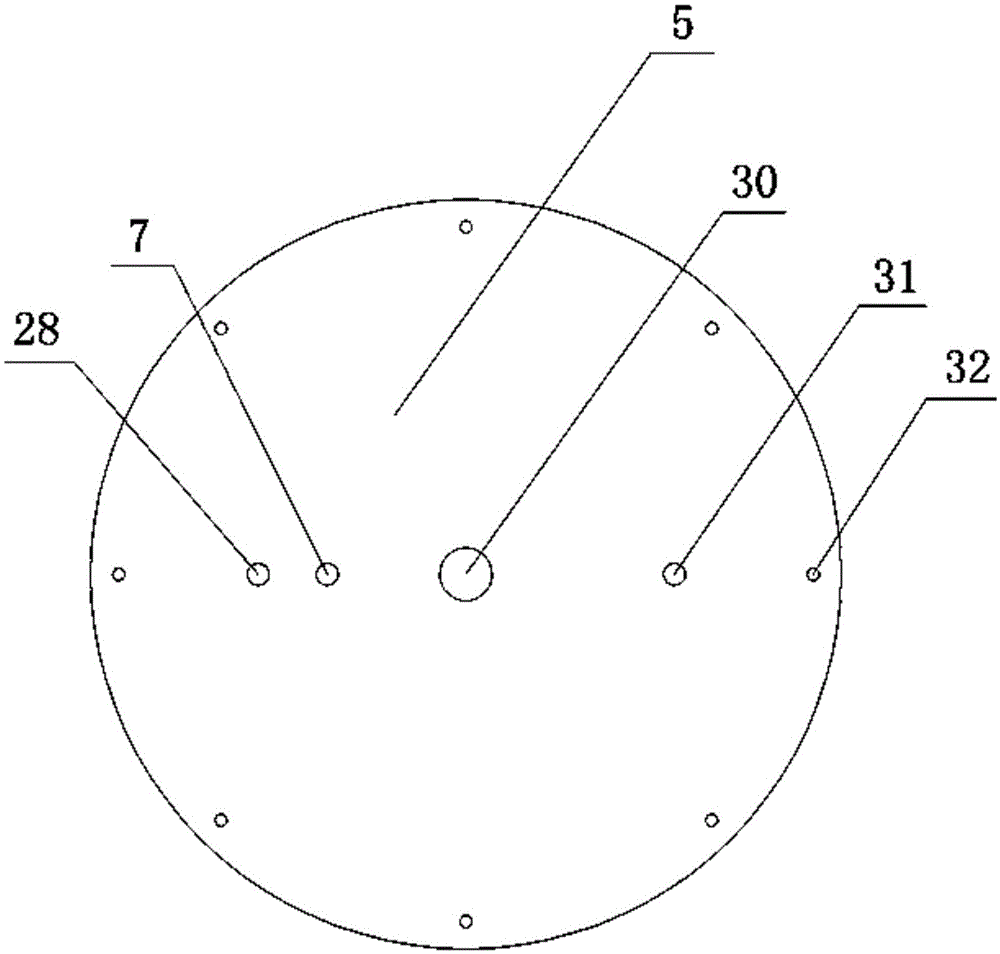

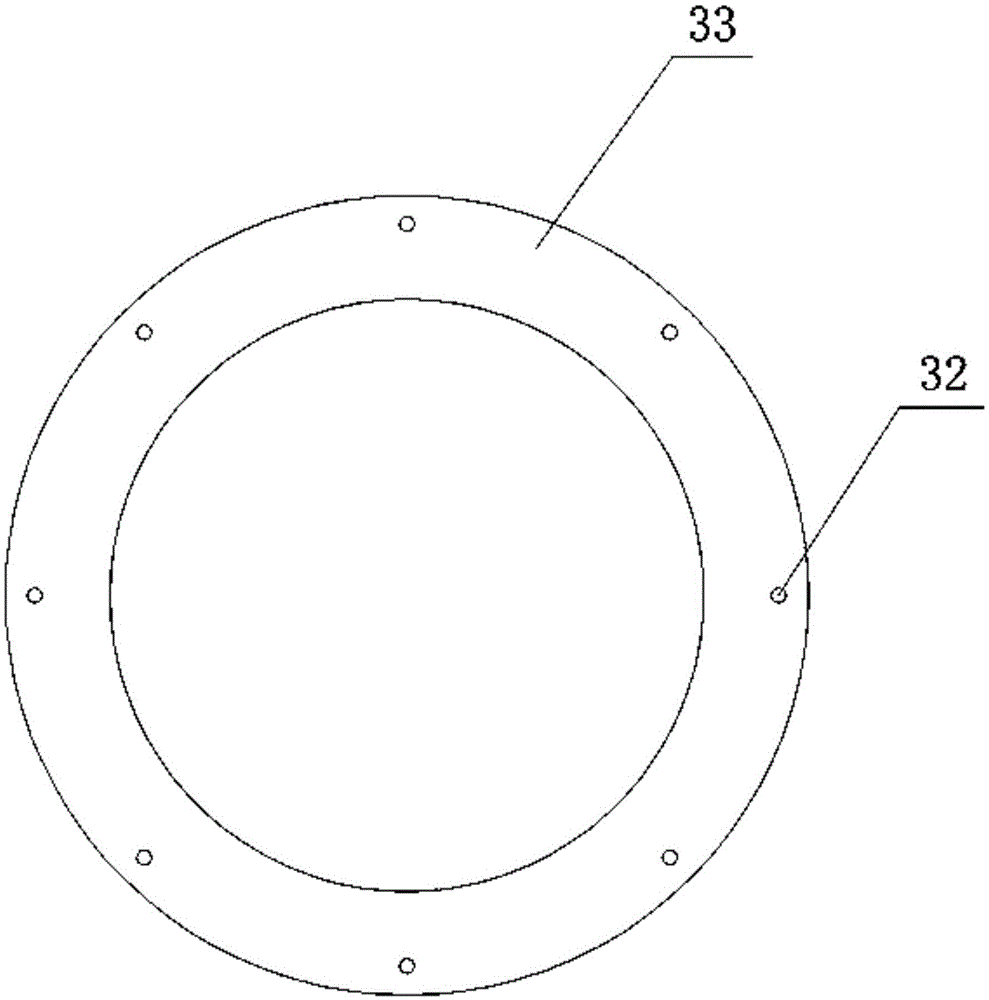

[0021] see figure 1 , figure 2 , image 3 , to further illustrate the present invention, the present invention includes: water inlet 1, outer cylinder 2, inner cylinder 3, feed inlet 4, cover plate 5, temperature sensor 6, biogas outlet 7, bottle stopper 8, pH value sensor 9, outlet Water outlet 10, biogas slurry outlet 11, return water conduit 12, return water outlet 13, water bath 14, intelligent controller 15, temperature sensor 16, heating rod 17, water pump 18, water supply conduit 19, ball valve 20, biogas residue outlet 21, biogas Reactor 22, stirring rod 23, electric wire 24, air inlet conduit 25, gas collecting bottle 26; drain conduit 27, temperature sensor interface 28, water outlet 29, stirring rod interface 30, pH value sensor interface 31, screw hole 32, annular Connection plate 33 . During implementation, the outer cylinder 2 and the inner cylinder 3 are first prepared, and then three holes are opened for the interface of the feed inlet 4, the biogas slurry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com