An uninterrupted bundling device and method based on a round bundling machine

A technology of a bundling device and a round baler, which is applied in the field of agricultural machinery and can solve problems affecting bundling efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing:

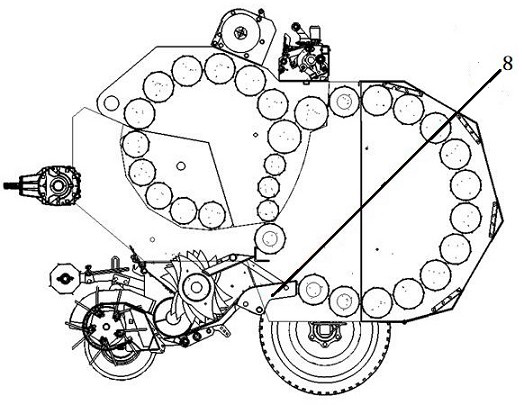

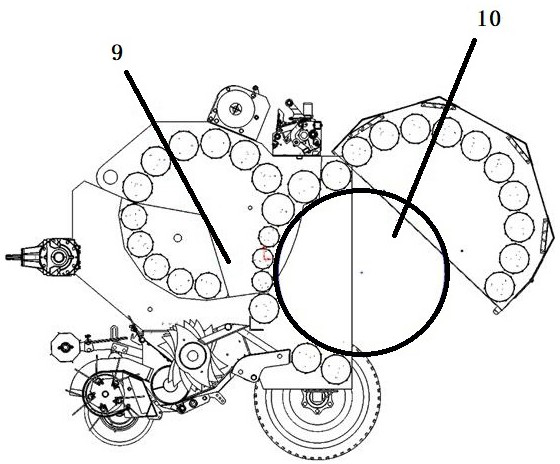

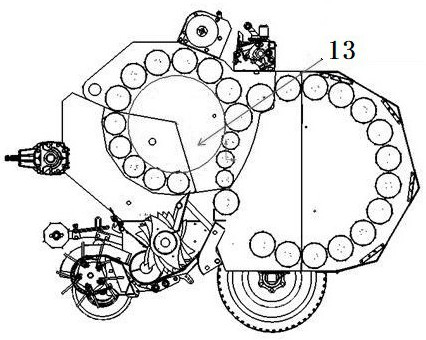

[0038] see figure 1 , an uninterrupted transfer mechanism based on a round baler, comprising a storage cabin 9 and a forming cabin;

[0039] The material storage compartment 9 includes the front movable upper shelf 1, the front movable lower shelf 2, the upper shelf axis fixed plate 4 and the lower shelf axis fixed plate 6; the upper shelf axis fixed plate 4 and the lower shelf axis fixed plate 6 mainly store material The cabin is fixed, and the front movable upper shelf 1 and the front movable lower shelf 2 are rotated around the axis. The front movable upper shelf 1 and the front movable lower shelf 2 are flexibly connected. The reversing mechanism of the rear gauge material guide switches the crop products to be transported to the forming and packaging compartment.

[0040] Under the above two cavities, there is also a reversing mechanism designed to stop and guide the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com