Polygonal box body forming device and method

A molding device, polygon technology, applied in packaging, transportation and packaging, box making operations, etc., can solve the problems of manual folding, low work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

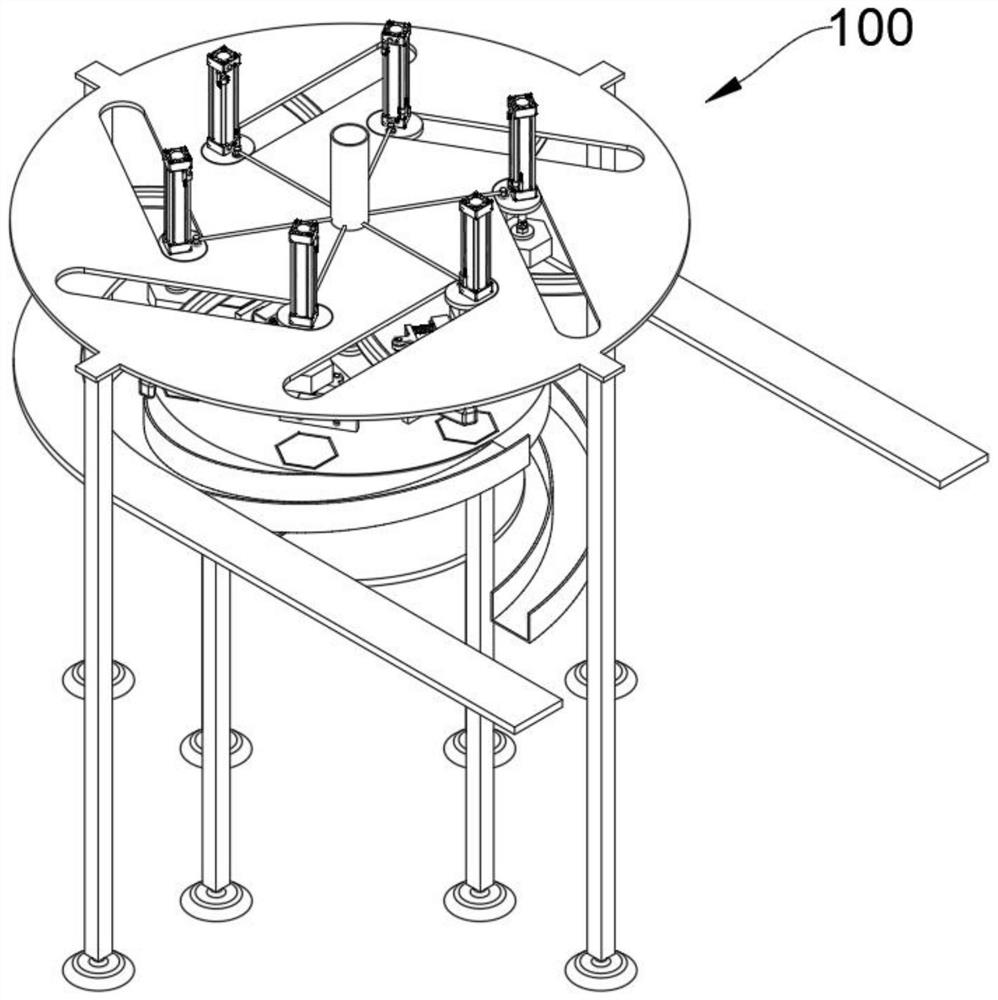

[0041] Refer to attached Figure 1~5 As shown, the present invention provides a technical solution: a polygonal box forming device, including a forming device 100, a forming mechanism 200, a pushing mechanism 300 and a retrieving mechanism 400;

[0042] Refer to attached Figure 1~5 as shown,

[0043] The molding device 100 includes a molding mechanism 200, a pushing mechanism 300 and a taking-up mechanism 400;

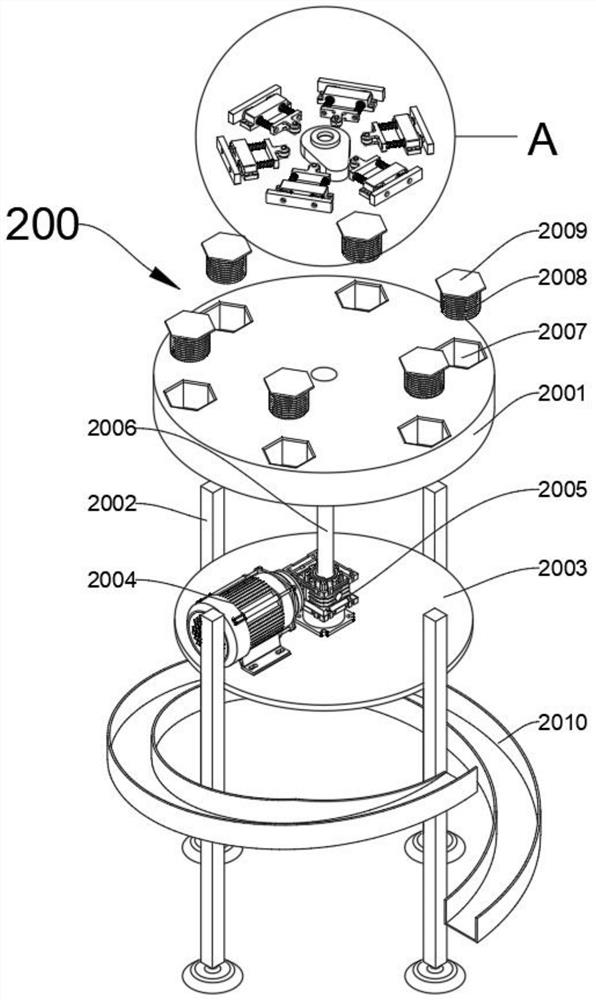

[0044] The forming mechanism 200 includes a workbench 2001, the top surface of the workbench 2001 is provided with a groove 2007, the shape of the groove 2007 is a regular hexagon, and the number of the groove 2007 is six, and the six grooves 2007 are equal to the number of the workbench 2001. The center is an array, and the center forms a circular array respectively on the top surface of the workbench 2001. The insides of the six grooves 2007 are provided with first springs 2008, and the tops of the six first springs 2008 are provided with cover plates 2009. The wo...

Embodiment 2

[0056] Refer to attached Figure 6 As shown, an operating method of a polygonal box forming device provided by an embodiment of the present invention further includes the following steps:

[0057] S1, equipment installation: install the forming device 100 at the center of the circular conveyor belt, and place the forming box collection box at the end of the slideway 2010;

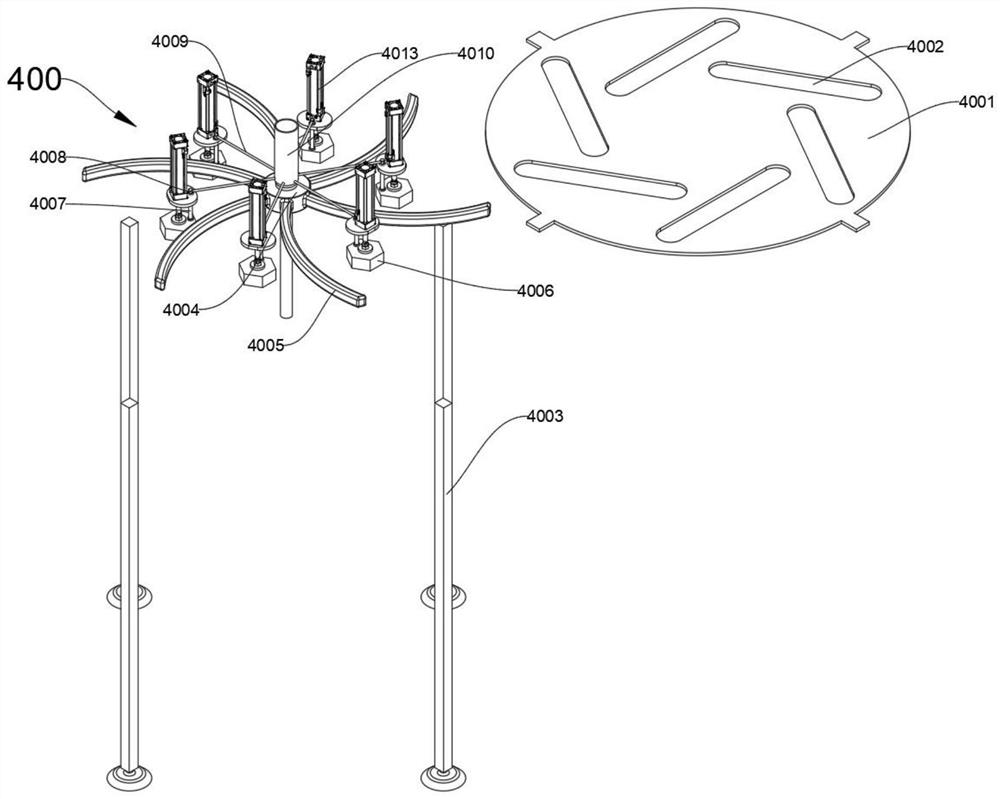

[0058] S2, material retrieving: after the cardboard is processed by the laminating machine and the cardboard cutting machine, it is conveyed through the endless conveyor belt, the forming device 100 starts to work, the motor 2004 rotates and is driven by the reducer 2005 and the transmission shaft 2006, and the rotation of the transmission shaft 2006 drives the rotation The column 4004 rotates to rotate the driving lever 4005, and the angles between the horizontal axis of the six strip holes 4002 and the line segments between the six strip holes 4002 and the center of the top plate 4001 are 45°, so when the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com