Winding packaging device for wrapping film packaging

A technology for stretch film and packaging, which is applied in the field of stretch film packaging devices, and can solve the problems of inconvenient stretch film packaging, inconvenient induction-type automatic cutting operation, and inconvenient multi-sided winding of workpieces. Packaging and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

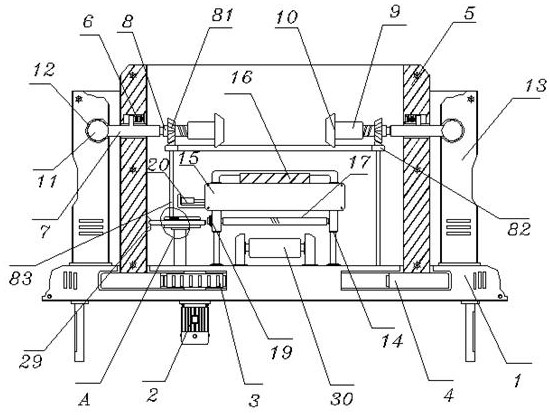

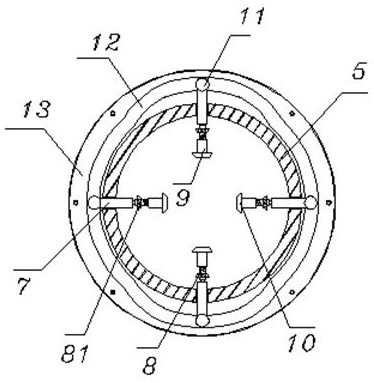

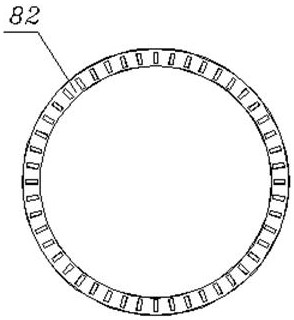

[0042] see Figure 1-4 , including a base 1, a motor 2 is fixed on the bottom of the base 1, and a guide gear 3 is connected to the output end of the motor 2, and a guide gear ring 4 is installed on the outer side of the guide gear 3, and the guide gear ring 4 and the guide gear 3 are embedded installed in the base 1, and the top of the guide tooth ring 4 is fixed with a mounting frame 5, and the mounting frame 5 is movably arranged above the base 1; On the side wall, a reinforcing spring 6 is fixed between the cross bar 7 and the inside of the mounting frame 5, and one end bearing of the cross bar 7 is connected with a mounting rod 8, and one end of the mounting rod 8 is provided with a mounting sleeve 9, and the mounting sleeve One end of 9 is bonded with a fixed block 10, and the fixed block 10 and the mounting sleeve 9 are all located on the inside of the mounting bracket 5, and the other end of the cross bar 7 is fixed with a guide ball 11, and the guide ball 11 is locate...

Embodiment 2

[0044] see figure 1 , Figure 5 Figure 10 , the difference from Embodiment 1 is: the stretch film roll assembly 30, the stretch film roll assembly 30 is installed on the upper end of the middle part of the base 1, and the top of the base 1 is connected with the positioning frame 15 through the elastic telescopic rod 14, and the positioning frame 15 The top is fixed with a heating plate 16, the positioning frame 15 is located above the stretch film roll assembly 30, and positioning rollers 17 are installed on the inner wall of the elastic telescopic rod 14 below the positioning frame 15, and a stretching assembly 18 is installed in the positioning frame 15, positioning The top of the frame 15 is connected with a pressure bar 152 through an elastic telescopic column 151 rotating shaft, and the pressure bar 152 is movably installed at the raised position on the top of the positioning frame 15; the stretching assembly 18 includes a first stretching roller 181 and a second stretc...

Embodiment 3

[0046] see figure 1 and Figure 6-9 , the difference from Embodiment 2 is: the pressure sensor 19, the pressure sensor 19 is fixed on the outside of the elastic telescopic rod 14, and the outside of the positioning frame 15 on the top of the elastic telescopic rod 14 is equipped with an electric push rod 20, and the electric push rod 20 The output end runs through the positioning frame 15 and is connected with a push frame 21, the push frame 21 is movably installed in the positioning frame 15, and the inner wall of the positioning frame 15 is connected with a mounting bar 23 by a return spring 22, and the side wall of the mounting bar 23 is fixed with a Blade 24, and the outside of mounting bar 23 is welded with push block 25; Mounting seat 26, mounting seat 26 is fixed on the top of base 1, and contact spring 27 is penetrated and installed with contact rod 28 in mounting seat 26, and contact rod 28 One end is located on one side of the pressure sensor 19, the other end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com