Formwork-erecting-free steel bar keel steel plate and concrete laminated slab and implementation method thereof

A reinforced keel and concrete technology, which is applied in the processing of floor slabs, building materials, building components, etc., can solve the problems of self-heavy weight of laminated slabs, inconvenient formwork support or formwork removal, etc. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

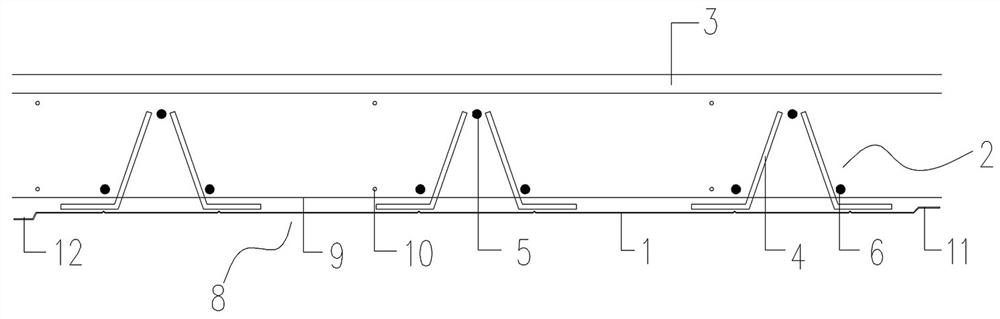

[0025] A method for implementing a formwork-free reinforced keel steel plate and a concrete laminated plate, comprising the following steps:

[0026] Step 1: Weld the steel bar trusses 2 to the bottom steel plate 1 at the prefabricated site. On the steel plate 1 and between the adjacent reinforcement trusses 2, a long reinforcing protrusion 7 is welded, and the bottom flange of the reinforcing protrusion 7 is welded to the bottom steel plate 1.

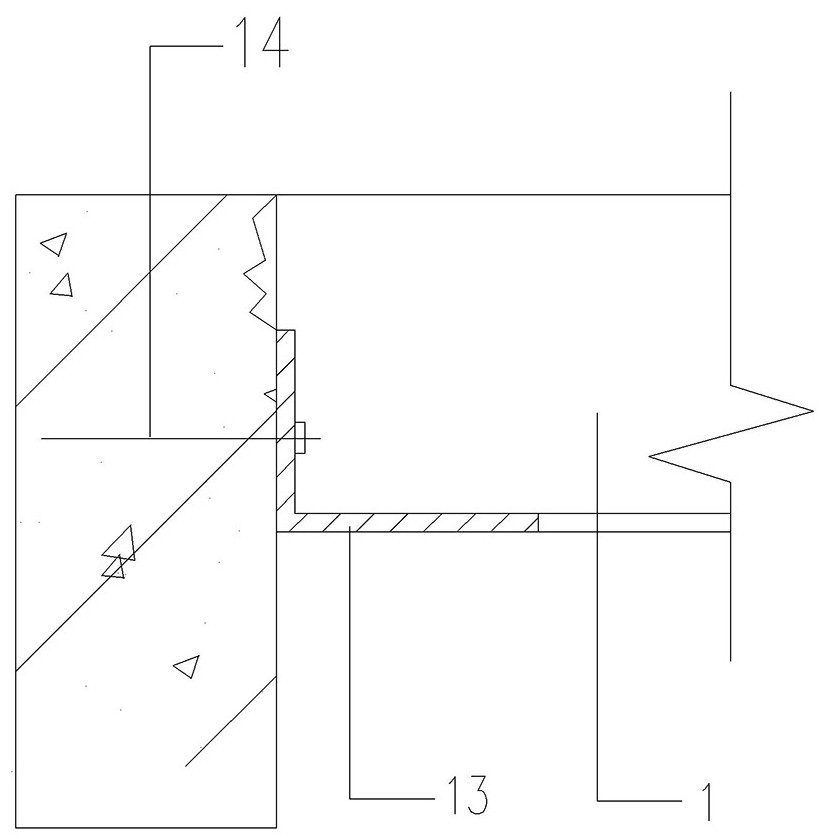

[0027] Step 2: hoist the bottom steel plate 1 that has been welded to the steel bar truss 2 and the reinforcing protrusion 7 to a predetermined position, fasten the edge of the adjacent bottom steel plate 1 through the upper groove 11 and the lower groove 12, and fasten the bottom steel plate 1 The width side is welded and fixed with the fixed beam angle steel 13 on the concrete beam, and then the two ends of the steel bar truss 2 are welded and fixed with the pre-embedded plate at the side of the concrete beam.

[0028] Step 3, weld...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com