Control device for automatically adjusting laser incident angle and using method thereof

A laser incident angle and automatic adjustment technology, applied in the field of laser measurement, can solve problems such as inability to compensate, exceed the receiving range, and poor incident light angle, so as to achieve good applicability and easy shock absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

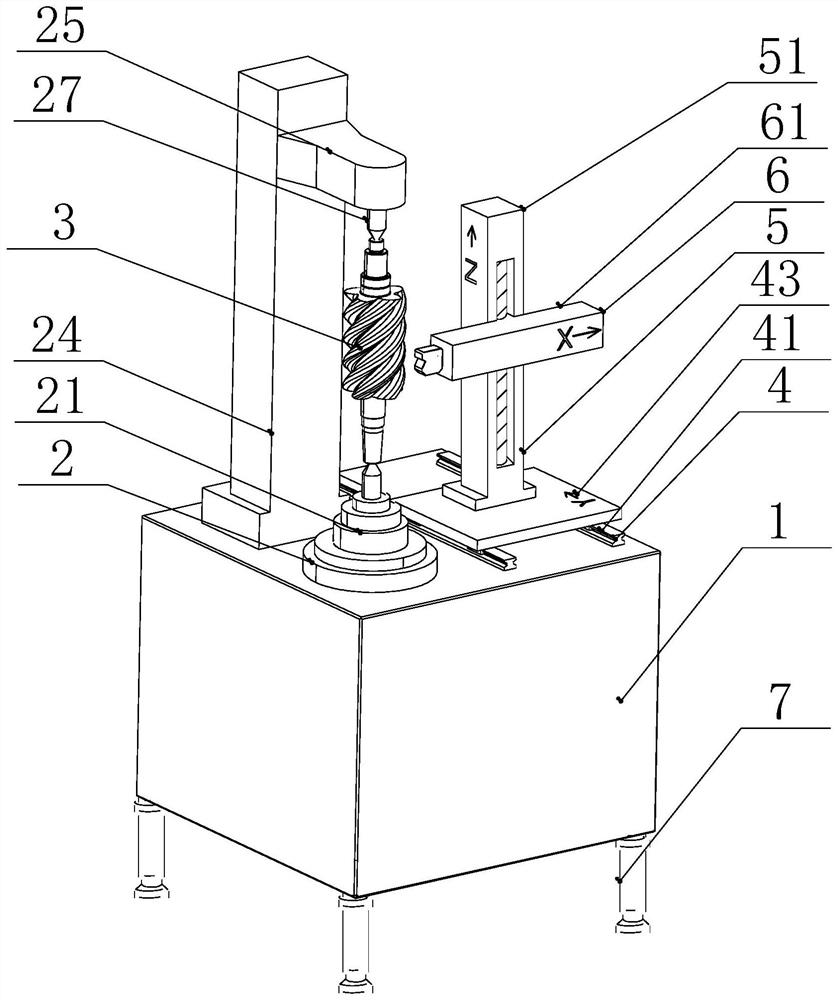

[0032] Such as figure 1 As shown, the present invention is a control device for automatically adjusting the incident angle of laser light and its use method, which includes a working box 1, and one end of the top of the working box 1 is provided with a clamping mechanism 2, which is convenient for clamping the workpiece 3, and the working box 1 is close to the clamping mechanism 2 The top of one end is equipped with a Y-axis moving mechanism 4, the top of the Y-axis moving mechanism 4 is equipped with a Z-axis moving mechanism 5, and one end of the outer wall of the Z-axis moving mechanism 5 is equipped with an X-axis moving mechanism 6. Through each axial moving mechanism, it is convenient to move the laser The position of the ranging sensor 64 and the dead corner at the bottom of the working box 1 are provided with a shock absorbing mechanism 7 to reduce the vibration of the device and facilitate the adjustment of the height of the working box 1 so that it remains horizontal....

Embodiment 2

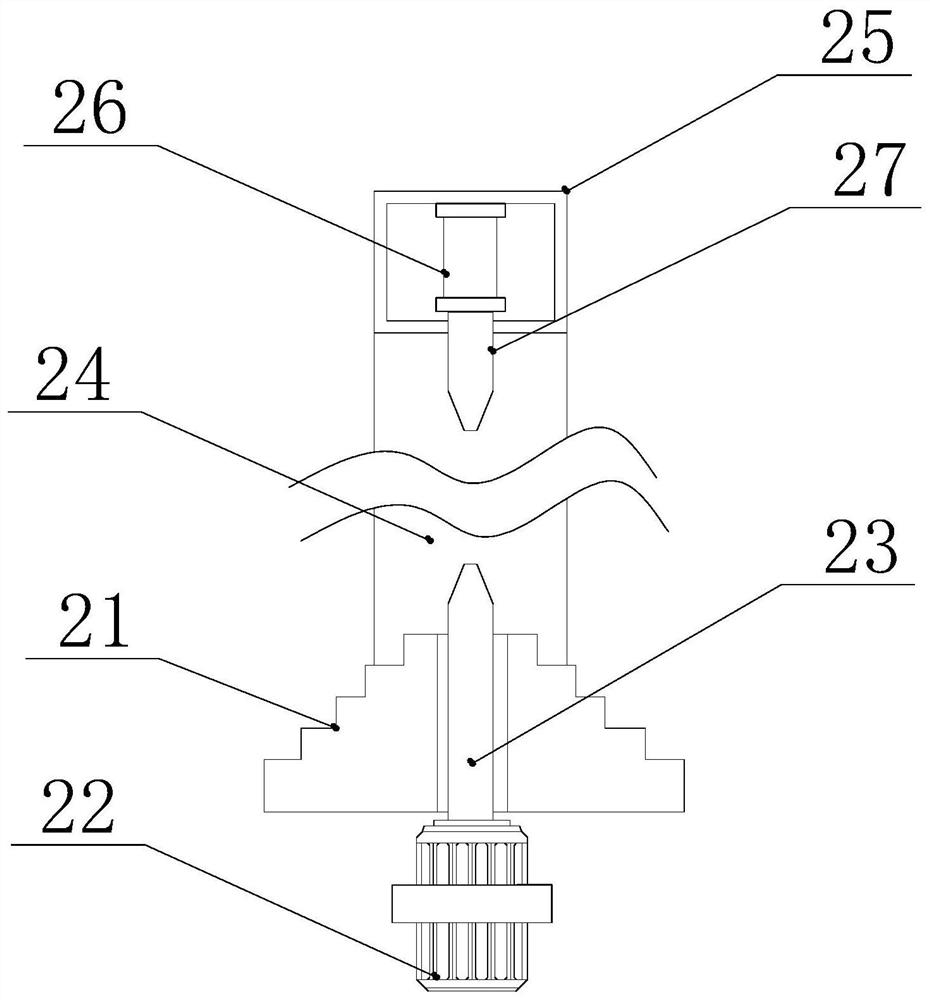

[0035] see Figure 1-2 , further improvements have been made on the basis of Example 1:

[0036] In order to quickly fix the workpiece 3, the clamping mechanism 2 includes a turntable 21 and a worktable 24. The turntable 21 is fixedly connected to one end of the top end of the outer wall of the work box 1, and the work box 1 is fixedly connected to a first stepper motor 22 at the bottom end of the turntable 21. The stepping motor 22 passes through the turntable 21 and is fixedly connected with the first ejector rod 23, and the first ejector rod 23 is driven to rotate by the first stepping motor 22, so as to facilitate the rotation of the workpiece 3 and change its angle.

[0037]In this embodiment, in order to adapt to different sizes of workpieces 3, the workbench 24 is fixedly connected to the top of the work box 1 near the end of the turntable 21, and the outer wall of the top block of the workbench 24 near the end of the turntable 21 is fixedly connected with a horizontal ...

Embodiment 3

[0039] see figure 1 , image 3 , Figure 4 and Figure 5 , further improvements have been made on the basis of Example 1:

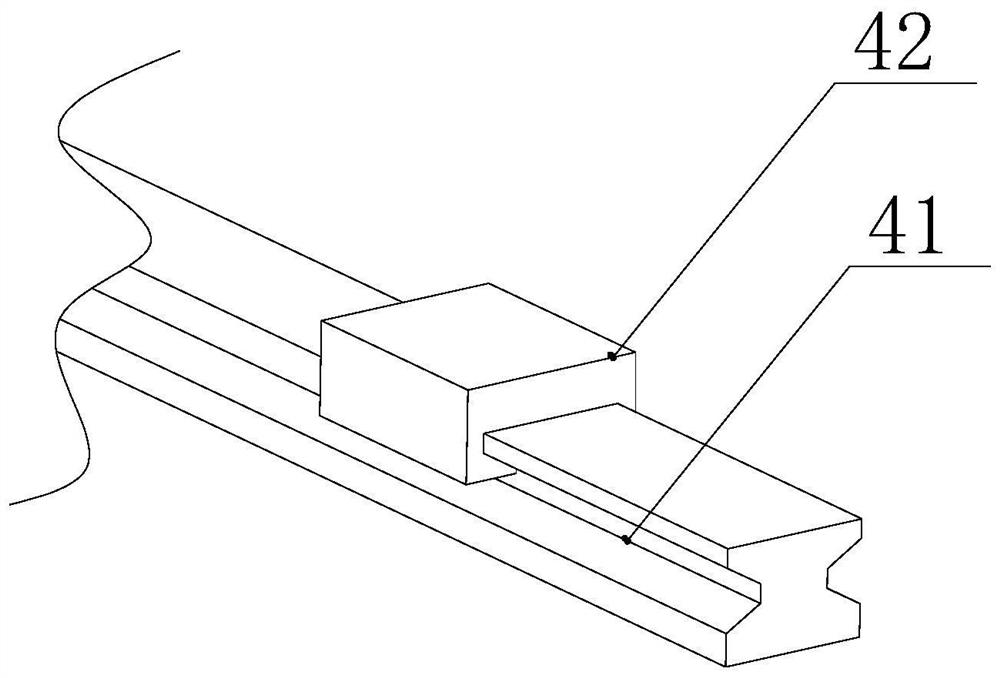

[0040] In order to move the laser ranging sensor 64 of the adjustment device along the Y axis, the Y axis moving mechanism 4 includes two rails 41, the two rails 41 are screwed on the top of the working box 1, and the two rails 41 are respectively slidingly connected with linear motors 42 , the number of linear motors 42 is four, and the four linear motors 42 are evenly distributed on the two rails 41, and the tops of the four linear motors 42 are fixedly connected to the bottom of the moving block 43, and the movement of the linear motors 42 is convenient to drive the laser distance sensor 64 moves, and at the same time can accurately control the position of its movement.

[0041] In this embodiment, in order to adjust the movement of the laser ranging sensor 64 along the Z axis, the Z axis moving mechanism 5 includes a vertical arm 51, the vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com