Available ways based on ultrasound interoperability technology ratio measurement methods for fluid flow rate

A fluid velocity and measurement method technology, applied in fluid velocity measurement, velocity/acceleration/impact measurement, measurement device, etc. The effect of the adjustable turndown ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

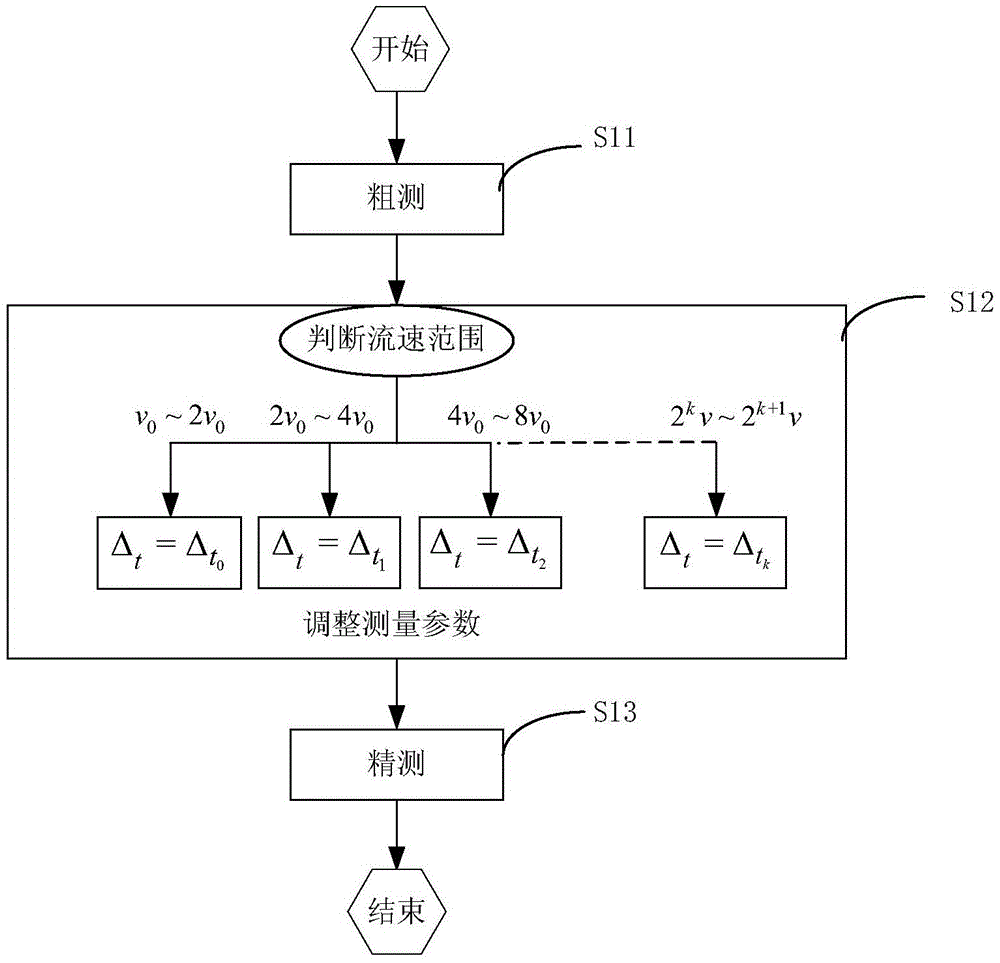

[0037] refer to figure 2 ,include:

[0038] Step S11) Use a lower pulse train frequency and a larger sampling time interval to roughly measure the current flow rate;

[0039] Step S12) Select the corresponding range range according to the rough measurement result and multiple preset measurement intervals to adjust the measurement parameters during precise measurement, including pulse train frequency and sampling time interval;

[0040] Step S13) Precise measurement to ensure that the measurement results meet the accuracy requirements;

[0041] In the above embodiment, it is assumed that the total number of sampling points N is 256, the upper limit of each preset measurement interval is 100, and the lower limit is 200, and the lag time meets the relevant detection requirements of random signals. Therefore, the ratio of the upper limit to the lower limit of each measurement interval is 2, then the relative error caused by the peak position is 0.5% to 1% in each interval.

[...

Embodiment 2

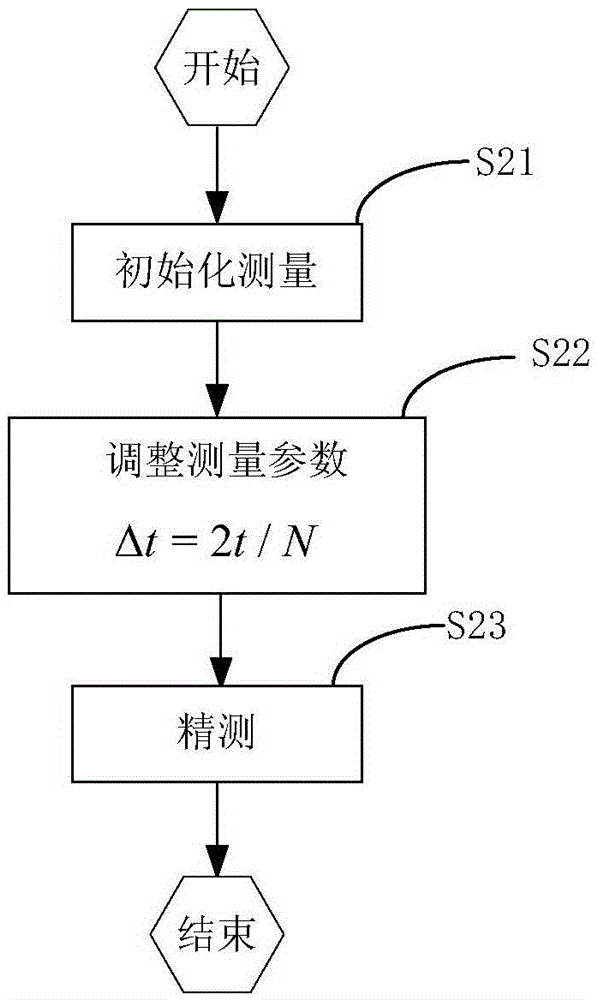

[0047] refer to image 3 ,include:

[0048] Step S21) Initialize the measurement, use a lower burst frequency and a larger sampling time interval, and roughly determine the lag time;

[0049] Step S22) Adjust measurement parameters according to the measured lag time, including burst frequency and sampling time interval;

[0050] Step S23) Precise measurement to ensure that the measurement results meet the accuracy requirements.

[0051] In this embodiment, in order to ensure a better correlation between the two signals and the accuracy of the correlation results, the number of lagging points n during fine measurement is around N / 2, so that the precise measurement results remain as Then the adjusted sampling time interval and burst time interval are Δ t =2t / N.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com