Bearing inner diameter surface detection probe

A surface detection and bearing technology, applied in the field of bearing inner diameter surface detection probes, can solve problems such as lack of detection probes, and achieve the effect of expanding the detection range and ensuring detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

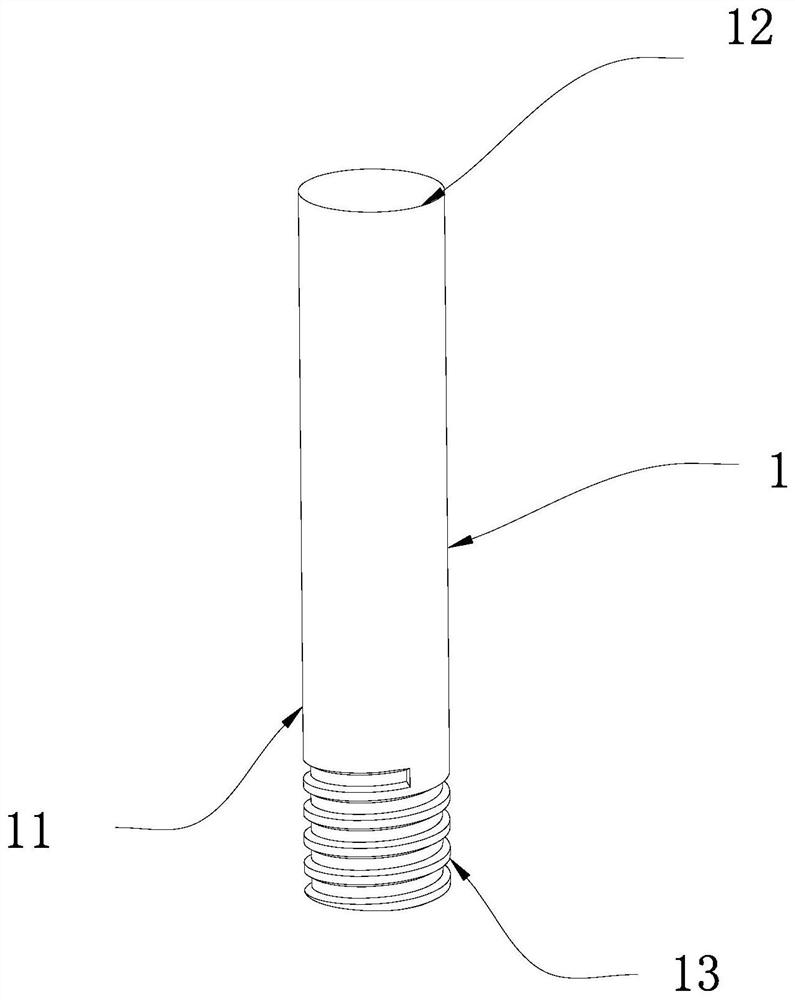

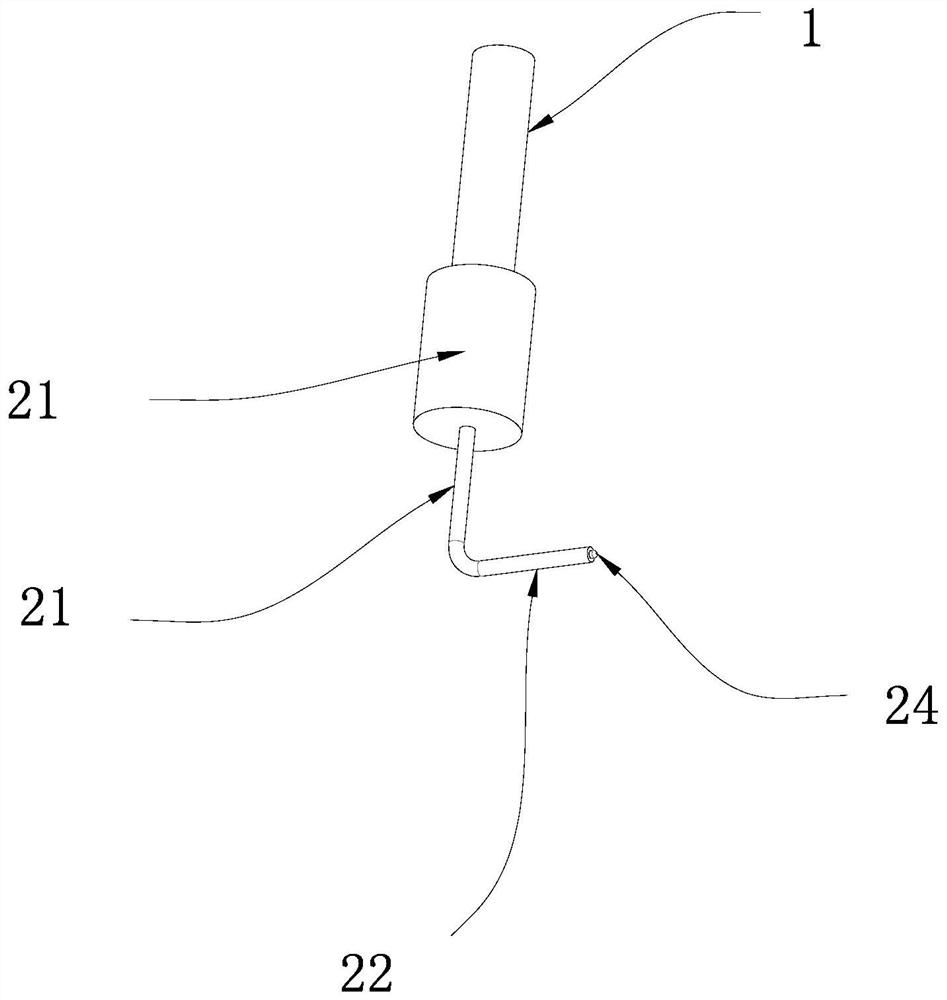

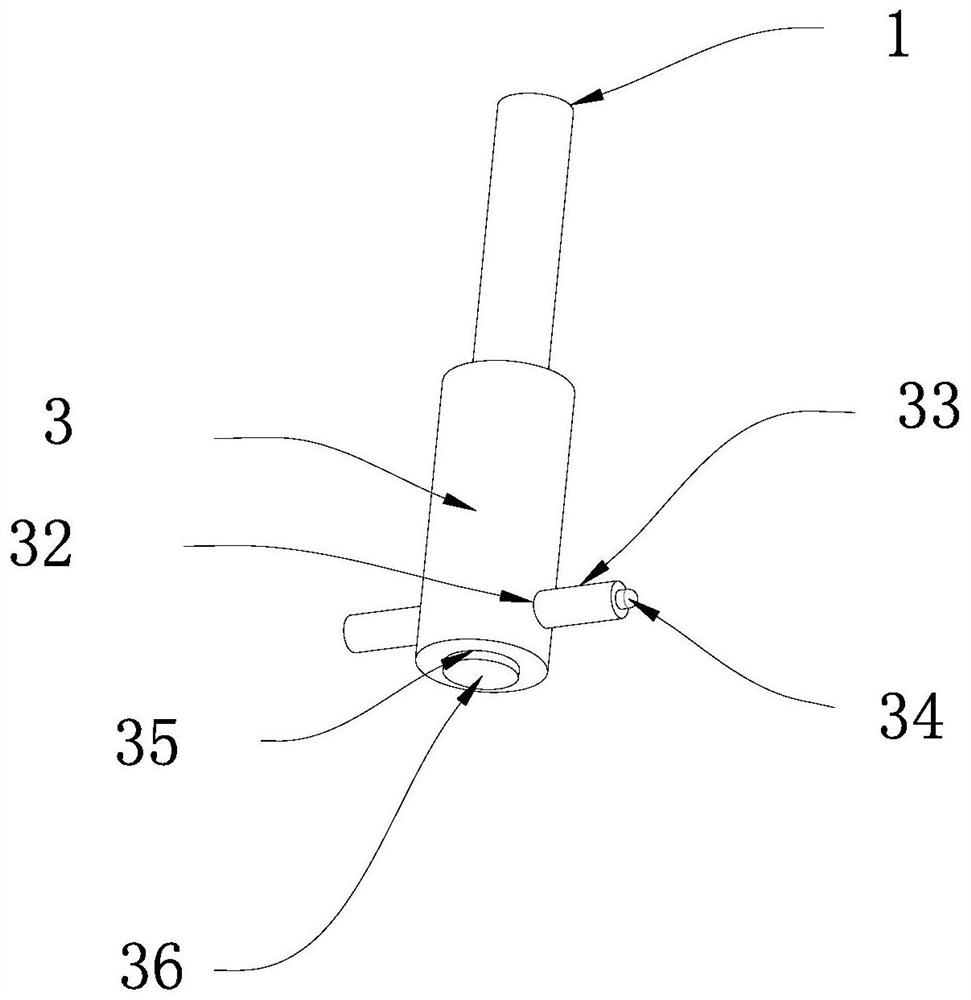

[0026]The present invention provides a bearing inner diameter surface detection probe, which includes a rod body 1, the top end of the rod body 1 is a detection end 11, and the end of the rod body 1 is a force end 12 for connecting with external driving equipment. The measuring end 11 is detachably provided with a first detection piece for single-point detection of the vibration moment of the inner diameter surface of the small bearing when it is running, or a second detection piece for single-point detection of the vibration moment of the inner diameter surface of the large bearing when it is running, or a second detection piece for multi-point detection. Azimuth detection The third detection part of the inner diameter surface vibration moment when the bearing is running or the fourth detection part for detecting the vibration moment of the inner ring side wall when the bearing is running or the third detection part for detecting the overturning moment of the inner ring side wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com