Vertical circuit breaker and high-voltage switchgear using vertical circuit breaker

A circuit breaker, vertical technology, applied in high-voltage/high-current switches, high-voltage air circuit breakers, electrical switches, etc., can solve the problem of high development cost, and achieve the effect of low research and development cost, convenient layout and height reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

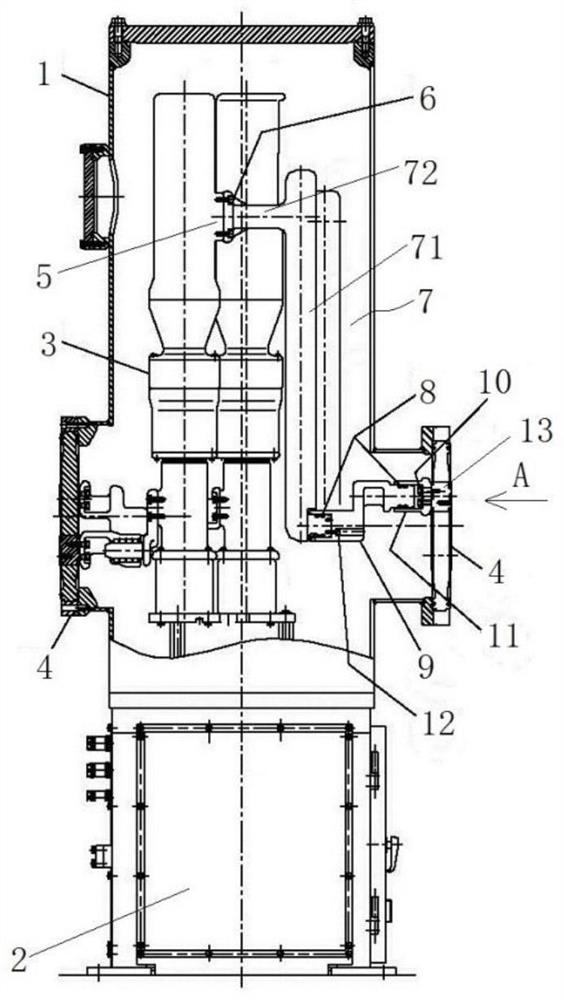

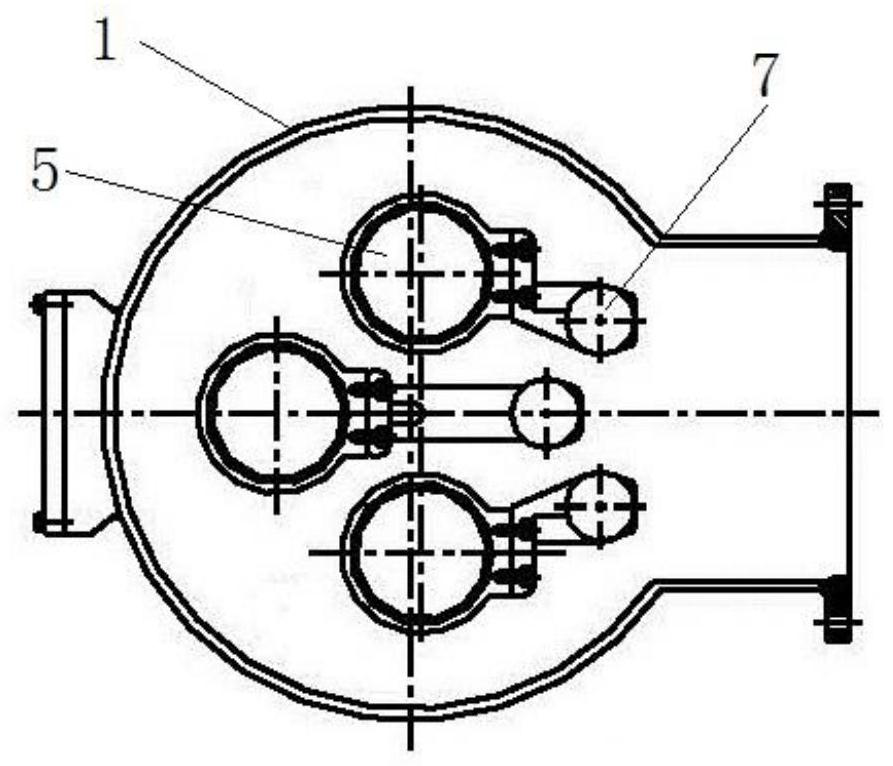

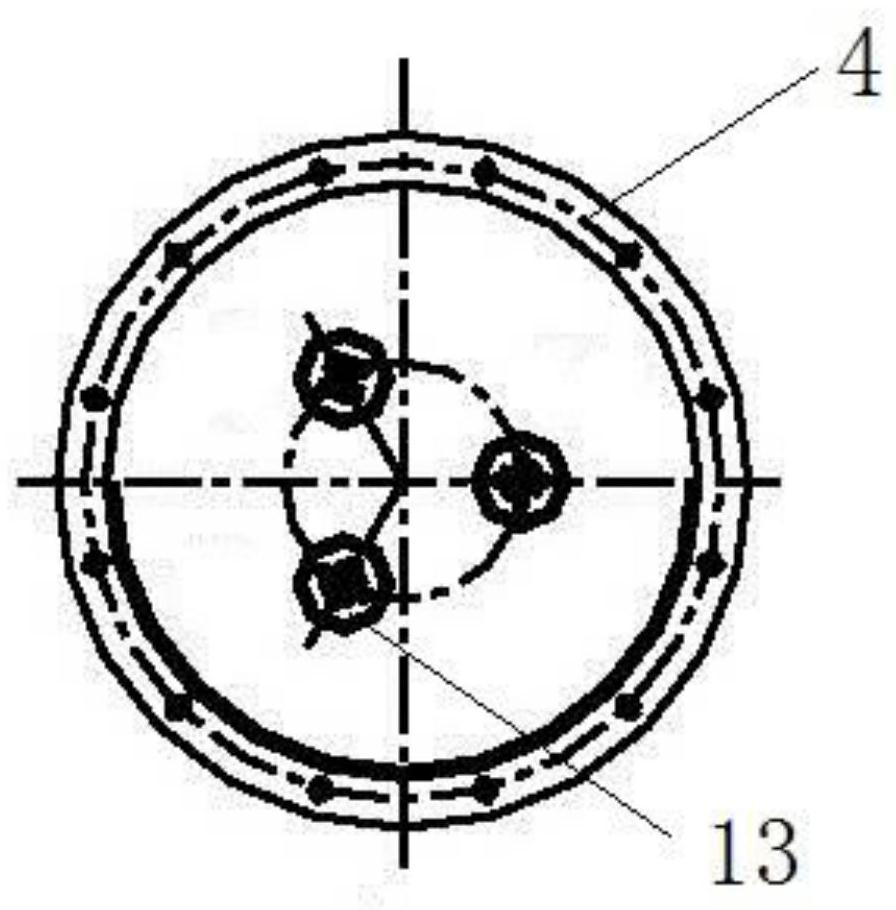

[0087] Such as Figure 1 to Figure 11 As shown, the vertical circuit breaker in this embodiment is a three-phase common box type circuit breaker. The vertical circuit breaker includes a housing 1, and a three-phase arc extinguishing chamber 3 is arranged in the housing 1. The housing 1 and the arc extinguishing chamber 3 are arranged up and down. Extending, the arc extinguishing chamber 3 includes a moving end at the bottom and a static end at the top, and an operating mechanism 2 capable of driving the moving end to move up and down is installed on the outside of the housing 1 . The two sides of the casing 1 are respectively provided with insulators 4, figure 1 The insulator 4 on the left side is used as the outgoing line at the moving end, and the insulator 4 on the right is used as the outgoing line at the static end. The insulator 4 on the right is located below the static end of the arc extinguishing chamber 3, and the static end of the arc extinguishing chamber 3 of eac...

specific Embodiment 2

[0105] Such as Figure 12 and Figure 13 As shown, the difference from Embodiment 1 is that in Embodiment 1, a port structure is arranged on the adjustment conductor. In this embodiment, in the vertical circuit breaker 19, a first port structure 14 and a second port structure 15 are arranged on the adjusting conductor 7, the first port structure 14 corresponds to the first bus bar 20 of the GIS, and the second port structure 15 It corresponds to the second bus 21 of the GIS. When in use, adjust conductors 7 of different lengths are selected according to the heights of the first GIS bus 20 and the second GIS bus 21 , and port structures are provided at corresponding positions of the adjust conductors 7 .

Embodiment 1

[0107] In Embodiment 1, by arranging the first connection part and the second connection part of the lead-out conductor in an offset position, the position of the second connection part can be adjusted while rotating the lead-out conductor. In this embodiment, the lead-out conductor has a straight rod structure, that is, the first connecting portion and the second connecting portion are located on the same straight line. At this time, no matter how the lead-out conductor is rotated, the circumferential position of the second connecting portion will not change. When the position of the second connecting part does not need to be changed, the vertical circuit breaker in the present invention can be a three-phase box-divided circuit breaker.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com