Engine oil control valve for engine VVT system and control method of engine oil control valve for engine VVT system

A technology for oil control valves and engines, which is applied in the direction of engine components, machines/engines, non-mechanical actuated valves, etc., can solve the problem of high cost, achieve simple structure, improve overall performance, and meet work requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below with reference to the accompanying drawings, through the description of the embodiments, the specific embodiments of the present invention, such as the shape, structure, mutual position and connection relationship between the various parts, the role and working principle of the various parts, etc., will be further described. Detailed instructions:

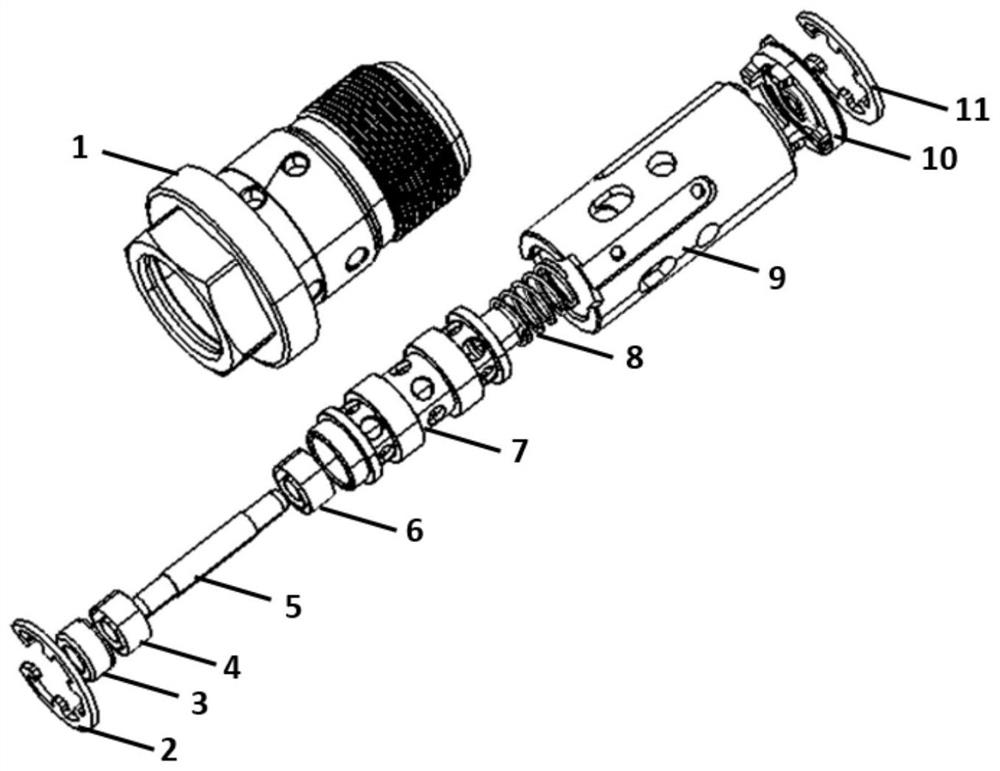

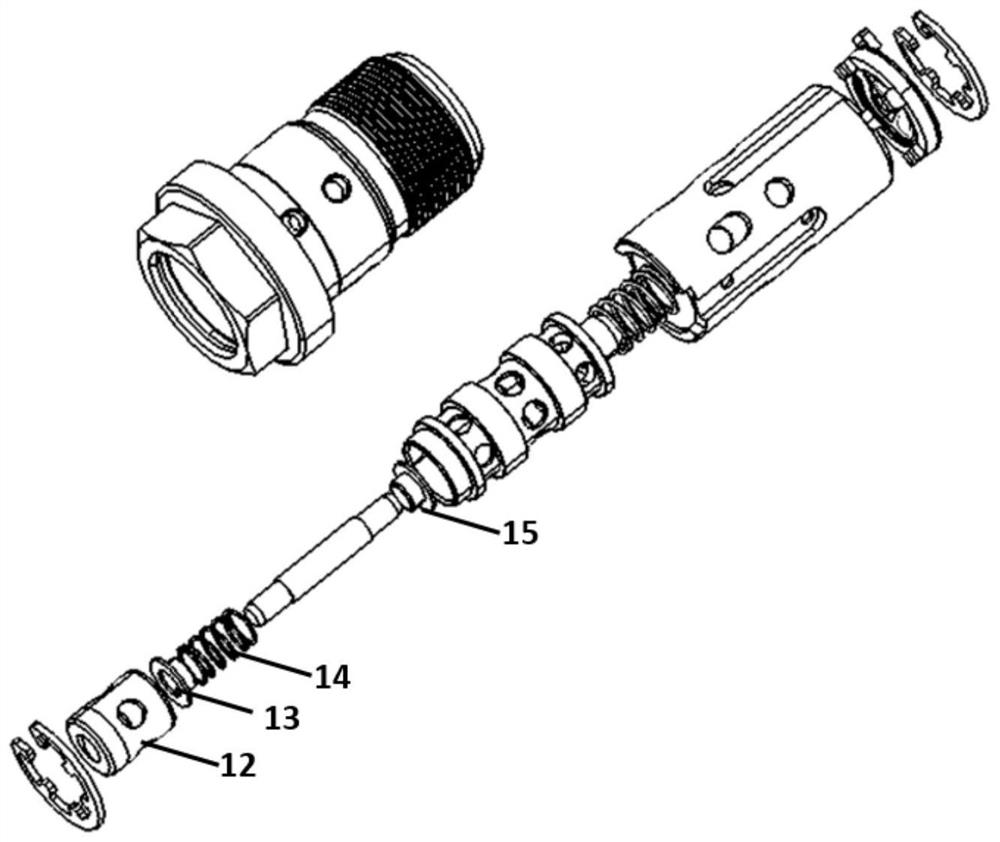

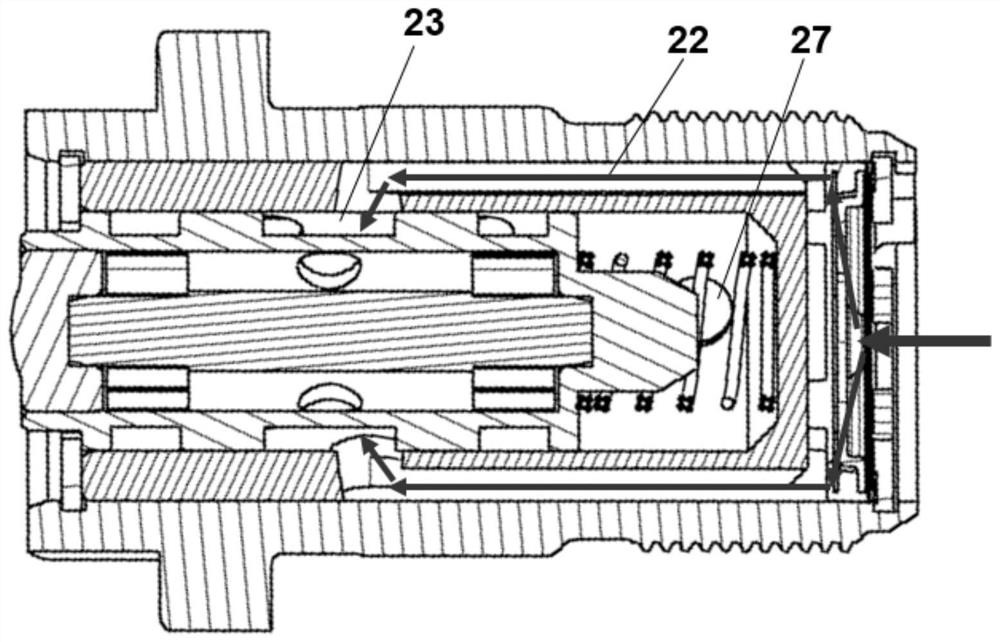

[0032] as attached figure 1 - attached Figure 4bAs shown, the present invention is an engine VVT system oil control valve, the valve sleeve 9 of the engine VVT system oil control valve is in clearance fit with the central bolt 1, one end of the valve sleeve 9 is provided with a retaining ring I2, and the other end of the valve sleeve 9 is provided with Retaining ring Ⅱ11; the valve core 7 and the valve sleeve 9 are in clearance fit, the compression spring 8 is located between the end of the valve sleeve 9 and the valve core 7; the check valve ring Ⅰ4 is fixed between the plug Ⅰ3 and the step of the positioning pi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap