Method for controlling oxidation of raw nuts

A technology of nuts and film-forming liquid, which is applied in the direction of food ingredients as antioxidants, food ingredients as antimicrobial preservation, edible seeds preservation, etc. It can solve the problems of accelerating nut oxidative rancidity, cumbersome material components, and increasing external pollution, etc. , to achieve the effect of simple and feasible method, slow down the respiratory metabolism process, and obvious film forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

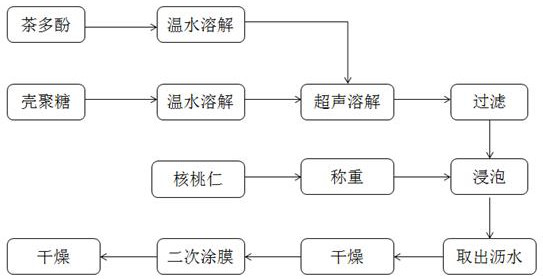

[0050] 1. Preparation of film-forming solution: Dissolve chitosan in 40-60 ºC mineral water according to 0.3-0.6% of the weight of the film-forming solution, and then stir on a magnetic stirrer for 10-15 min at a stirring speed of 750-800 rpm, magnetic stirrer heating temperature 40~60°C.

[0051] 2. Preparation of coating solution: Add tea polyphenols to the film-forming solution according to 0.1-0.2% of the weight of the coating solution, put it on the stirrer again and mix for 10-15 minutes, and then under the condition of 40-60ºC, ultrasonic Treat for 10~15min under the power of 200W.

[0052] 3. Pretreatment of the coating solution: filter the mixed coating solution through a 30-mesh screen to remove mechanical impurities, improve the plasticizing effect, and collect uniform coating solution.

[0053] 4. Treatment of walnut coating: put the walnut kernels into the coating liquid and soak for 3~5s, then take them out;

[0054]5. Treatment of walnut film formation: put th...

Embodiment 1

[0057] The method for the present embodiment to control the oxidation of raw nuts comprises the following steps:

[0058] Step 1. Preparation of film-forming solution: Weigh 0.8g chitosan and dissolve in 200ml mineral water at 50ºC, place in a magnetic stirrer and stir to dissolve for 10min. The temperature of the magnetic stirrer is set at 50ºC, and the stirring speed is set at 750 rpm.

[0059] Step 2. Preparation of coating solution: After stirring and dissolving, add 0.4g of natural antioxidant tea polyphenols to the film-forming solution, place in a magnetic stirrer and stir to dissolve for 10 minutes, set the temperature of the magnetic stirrer to 50ºC, and set the stirring speed to 750rpm , with an ultrasonic power of 200W, dissolved and degassed at 50ºC for 10 minutes, filtered through a 30-mesh sieve, and the filtrate collected was the coating solution.

[0060] Step 3. Coating of walnuts: Take 100g of walnuts and soak them in the coating solution for 5s, take them ou...

Embodiment 2

[0067] The method for the present embodiment to control the oxidation of raw nuts comprises the following steps:

[0068] Step 1. Preparation of film-forming solution: Weigh 0.8g chitosan and dissolve it in 200ml mineral water at 40ºC, place it in a magnetic stirrer and stir to dissolve for 10min. The temperature of the magnetic stirrer is set at 40ºC, and the stirring speed is set at 750rpm.

[0069] Step 2. Preparation of coating solution: After stirring and dissolving, add 0.4g of natural antioxidant tea polyphenols to the film-forming solution, place in a magnetic stirrer and stir to dissolve for 10 minutes, set the temperature of the magnetic stirrer to 40ºC, and set the stirring speed to 750rpm , dissolved and degassed at 50ºC for 10 minutes at an ultrasonic power of 200W, filtered through a 30-mesh sieve, and collected the filtrate for later use.

[0070] Step 3. Coating of walnuts: Take 100g of walnuts and soak them in the coating solution for 5s, take them out and pla...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap