Tube pulling mechanism for cosmetic packaging bottle

A packaging bottle and cosmetics technology, which is applied in the field of cosmetic packaging bottle processing, can solve problems such as low work efficiency, a large amount of manpower, and single operation mode, and achieve the effect of facilitating stretching processing and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

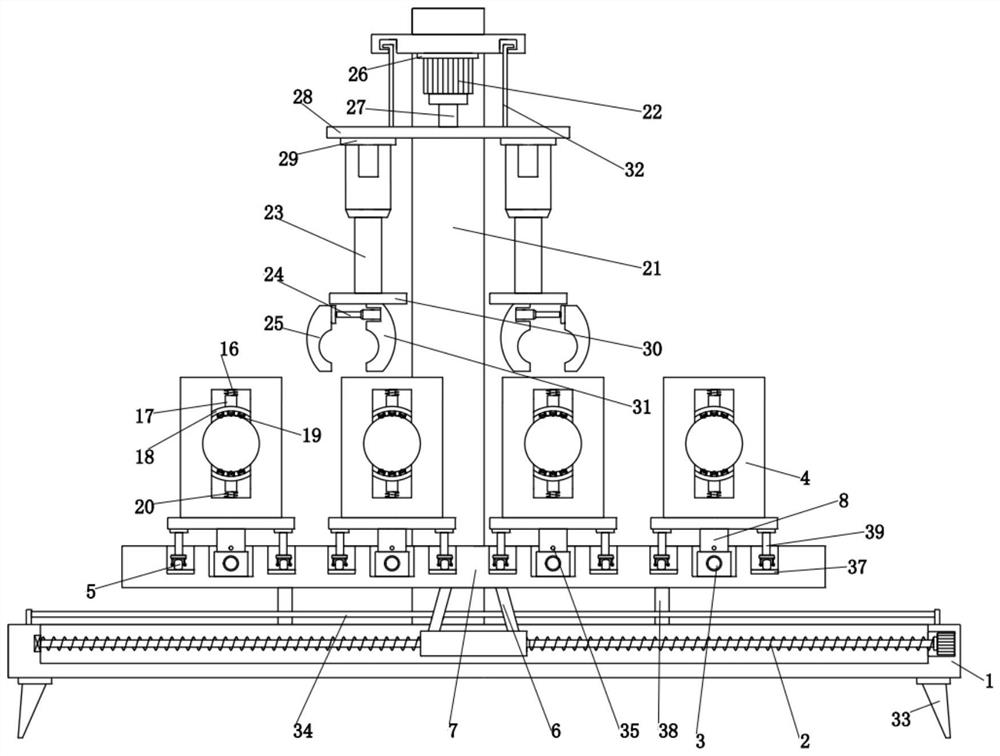

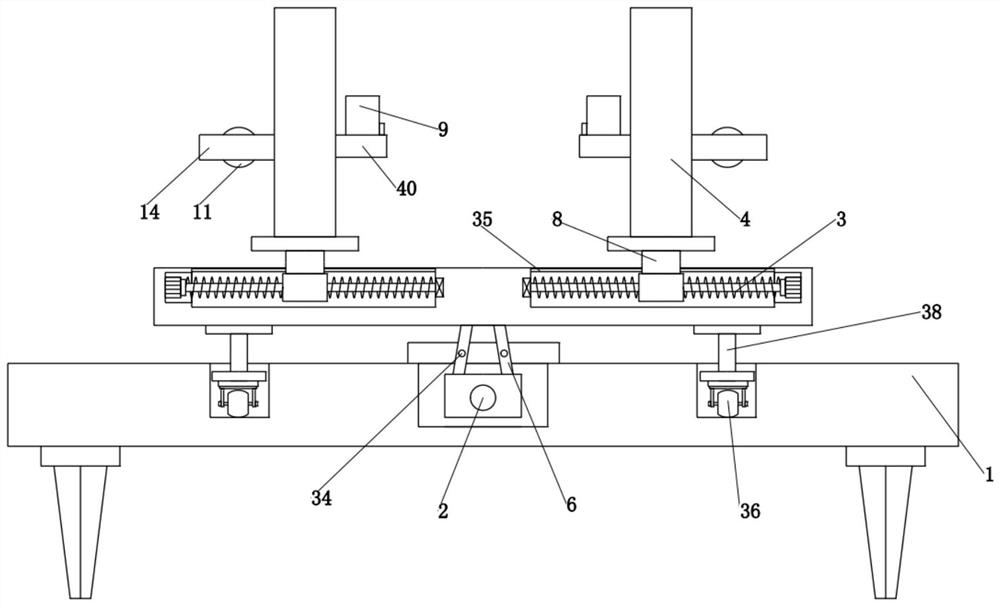

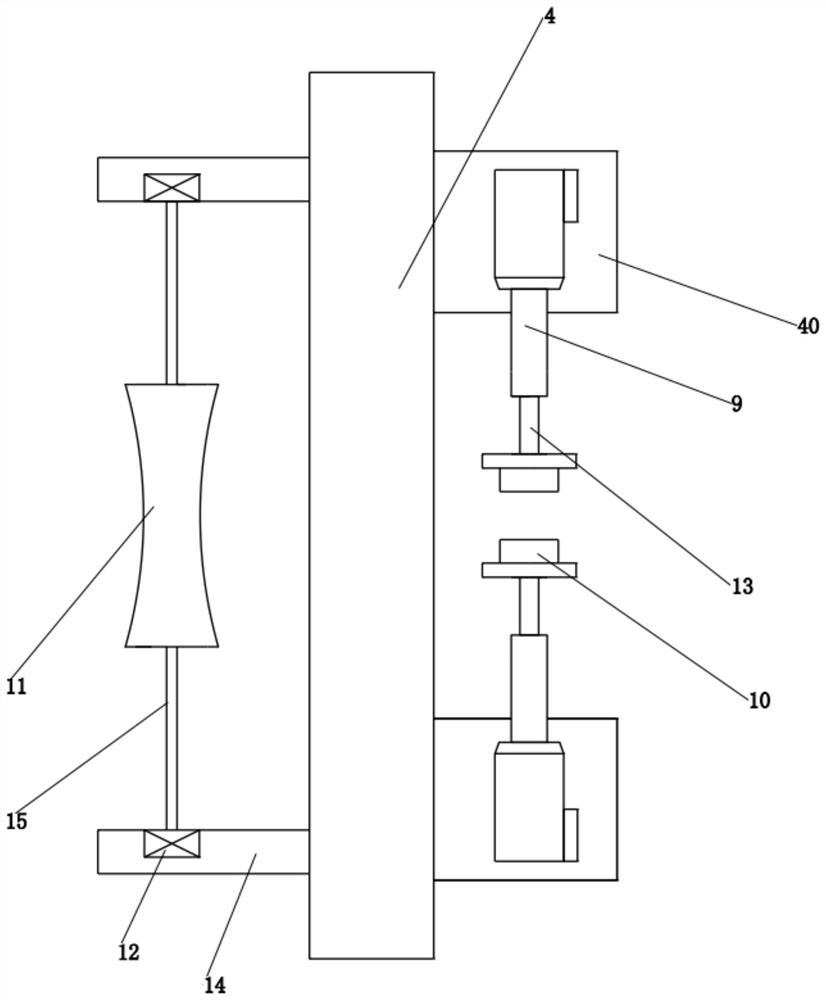

[0023] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-4 As shown, a tube pulling mechanism for cosmetic packaging bottles includes a rectangular base 1, the upper wall of the rectangular base 1 is provided with a tensile structure, and the tensile structure is provided with a positioning and clamping structure, and the rectangular base 1 and A positioning load-bearing structure is located above the tensile structure; the tensile structure includes: the first screw module 2, the second screw module 3 and the bearing frame 4; the upper wall of the rectangular base 1 is provided with a first bar-shaped groove , the first lead screw module 2 is placed inside the first bar-shaped groove, the first support frame 6 is installed on the moving end of the first lead screw module 2, and the operation panel 7 is fixed on the upper wall of the first support frame 6 for operation. The upper wall of the plate 7 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com