Cold rolling mill convenient for guiding feeding and discharging and used for alloy strips and using method

A technology of feeding and discharging, cold rolling mill, applied in the field of cold rolling mill, can solve problems such as deviation, achieve the effect of preventing deviation and facilitating feeding and discharging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The implementation of the present application will be described in detail below with reference to the accompanying drawings and examples, so as to fully understand and implement the implementation process of how the present application uses technical means to solve technical problems and achieve technical effects.

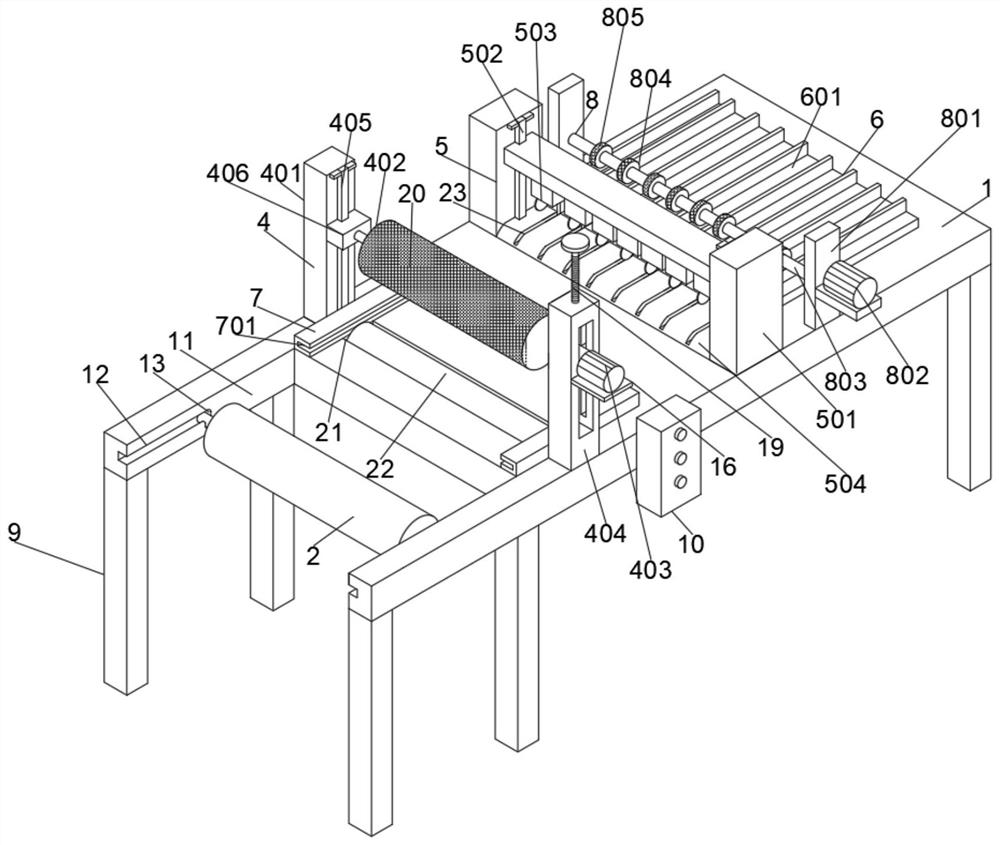

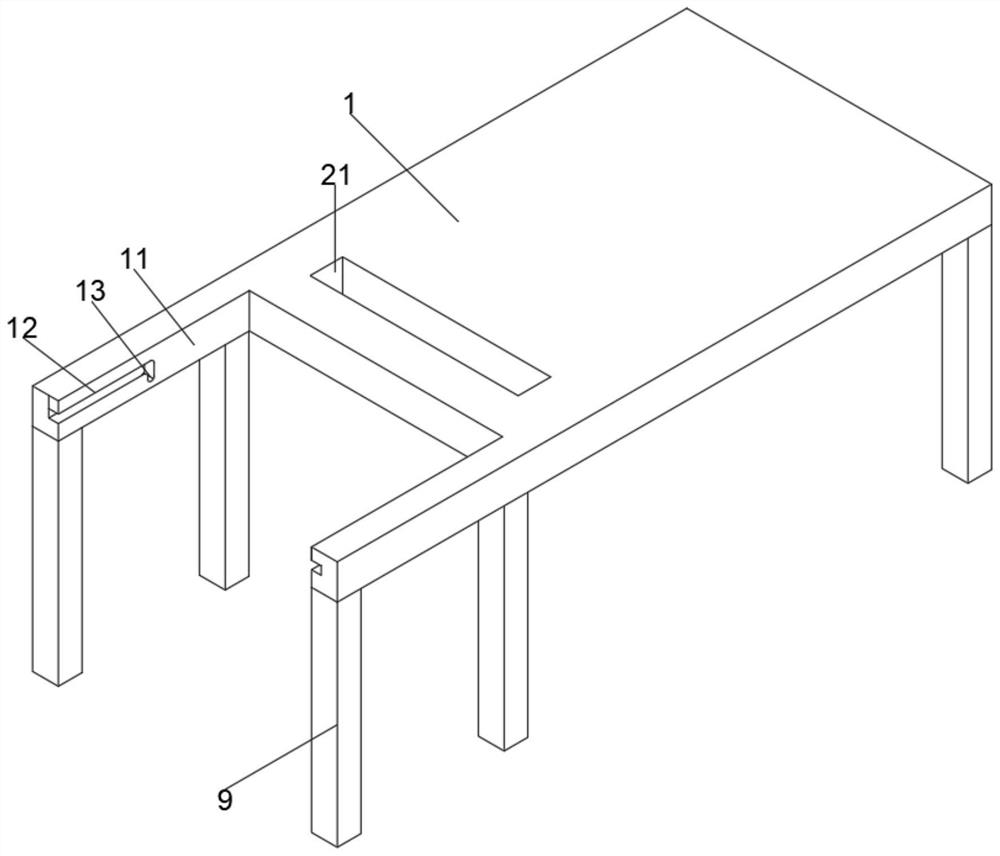

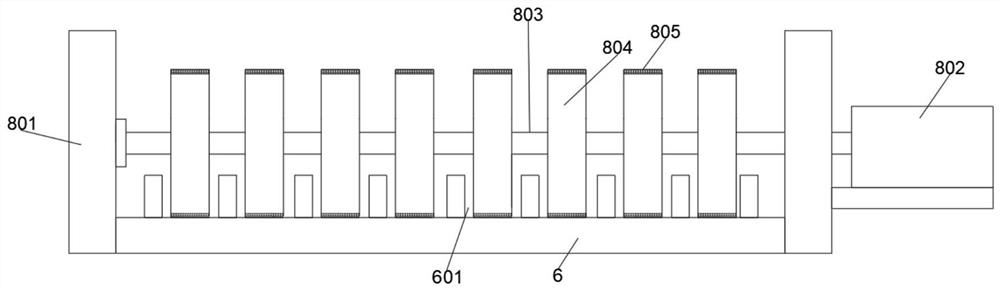

[0036] Such as Figure 1-Figure 8As shown, the cold rolling mill for alloy strips provided in this embodiment is convenient for guiding in and out of materials, including a processing table 1, and an alloy coil rolling drum 2 is arranged on one side of the processing table 1, and the alloy coil rolling drum 2 is used for For the placement of the alloy sheet, the upper end surface of the processing table 1 is sequentially provided with an alloy sheet conveying mechanism 4, a cold-rolled dividing mechanism 5, and a discharge channel 6. The alloy sheet conveying mechanism 4 includes a first support plate 401, a second support plate 404, The first conveying roll...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap