Part placing frame device for automobile part welding

A technology for auto parts and components, which is applied in the direction of tool storage devices, drying gas arrangement, dryers, etc., which can solve the problems of parts that cannot be placed in layers, affect the use effect, and be inconvenient to find, etc., so as to reduce the occupied area , easy to replace, easy to layer the effect of placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

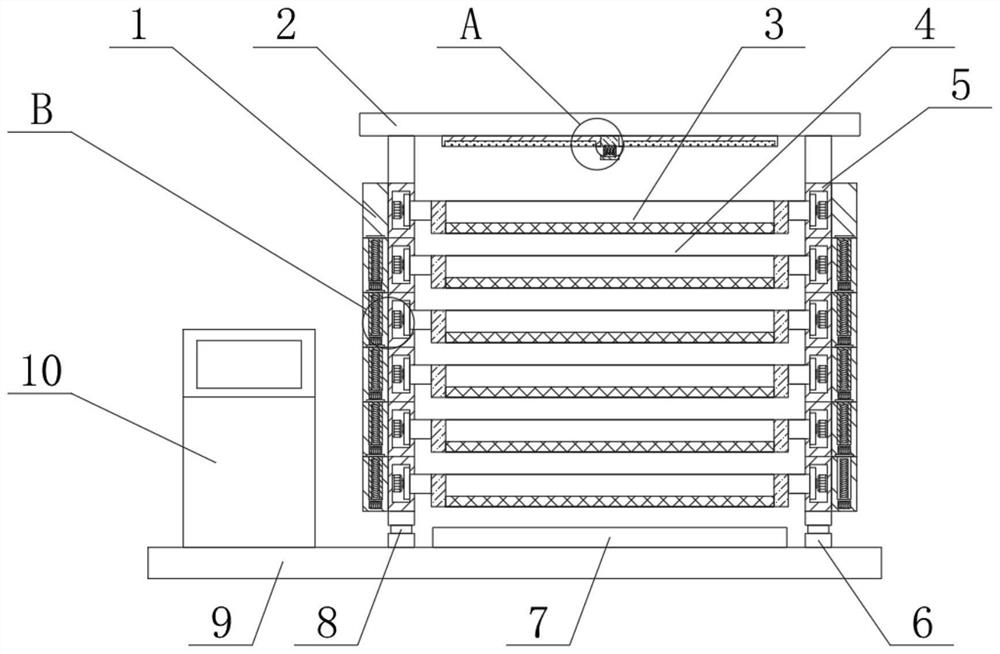

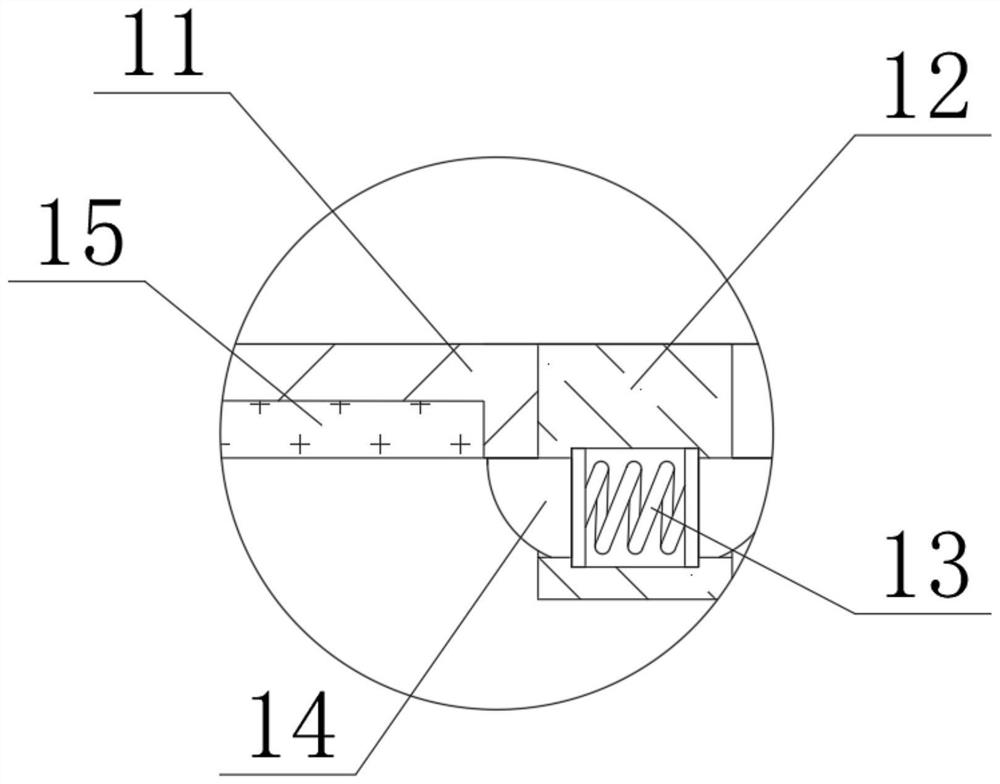

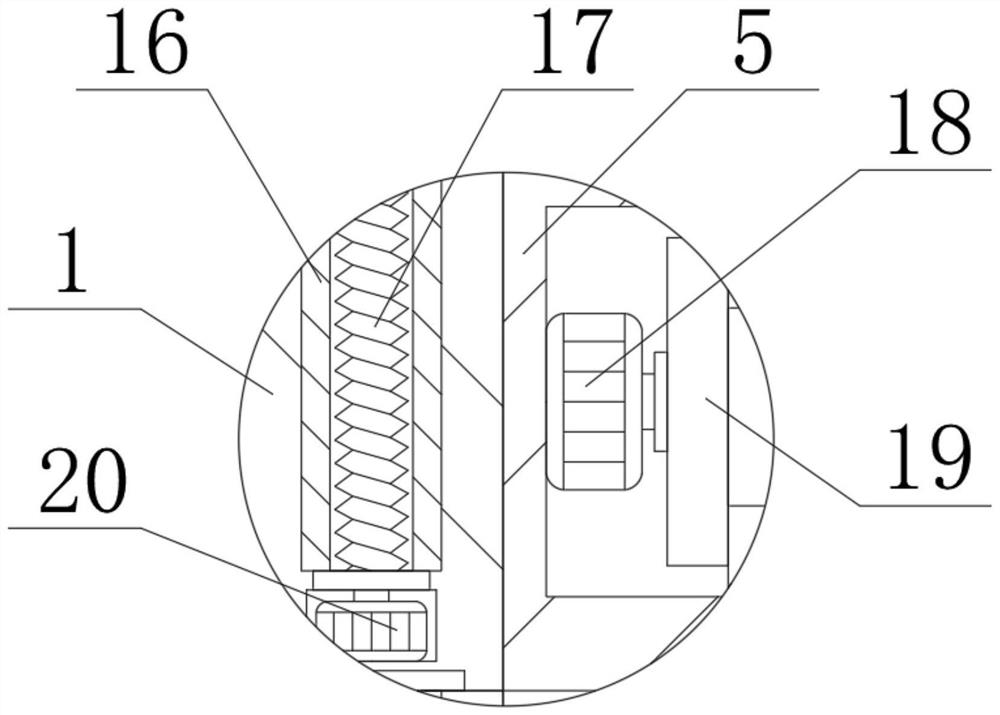

[0033] see Figure 1-6 , the present invention provides a technical solution:

[0034] A component placing rack device for auto parts welding, comprising a placing box 3, a lifting frame 5 and a bottom plate 9, the upper side of the right end of the bottom plate 9 is provided with a placing box 3, and the upper sides of the left and right ends of the placing box 3 are fixedly connected There is a turret 19, the turret 19 is rotatably connected in the lifting frame 5, the lifting frame 5 is arranged on the left and right sides of the placement box 3, and the lifting plate 1 is fixedly connected to the end of the lifting frame 5 away from the placement box 3, so The upper side of the lifting plate 1 is slidingly connected with a driving plate 16, and the driving plate 16 is fixedly connected to the bottom end of another lifting plate 1, and the bottom side of the driving plate 16 is provided with a threaded groove, and the driving plate 16 A threaded rod 17 is spirally connecte...

Embodiment 2

[0038] see Figure 7-8 , the present invention provides a technical solution:

[0039] The bottom end of lifting frame 5 is fixedly connected with support rod 25, and support rod 25 is provided with a plurality of, and support rod 25 is slidably connected in buffer frame 28 upper side, and buffer frame 28 is fixedly connected on the base plate 9, and buffer frame 28 is provided with Air chamber 27, air chamber 27 is provided with a plurality of, a plurality of air chambers 27 are connected through through chamber 29, and the upper side of air chamber 27 is sealed with piston plate 26, and the upper end of piston plate 26 is fixedly connected with support rod 25, and The front end of the chamber 27 is sealed with an air injection pipe 31, which is fixedly connected in the buffer frame 28, and the air injection pipe 31 is sealed with a check valve 30, through the air chamber 27 and the piston plate 26, the energy on the device can be absorbed , to increase the stability of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com