Slicing device for ham

A technology for slicing device and ham, which is applied in the direction of using liquid cleaning method, cleaning method, utensils, instruments, etc., can solve problems such as inconvenient cleaning, and achieve the effect of easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

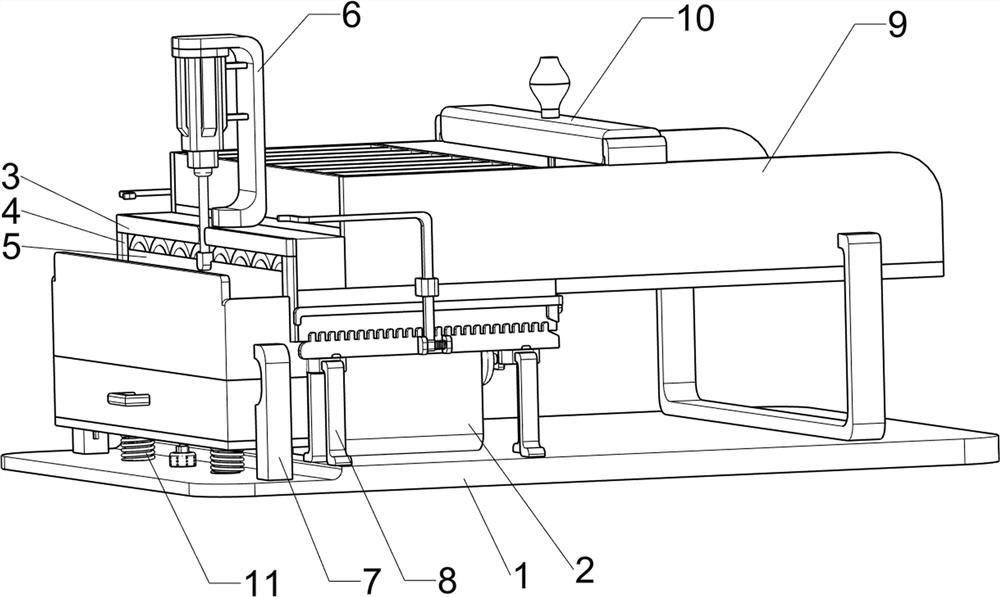

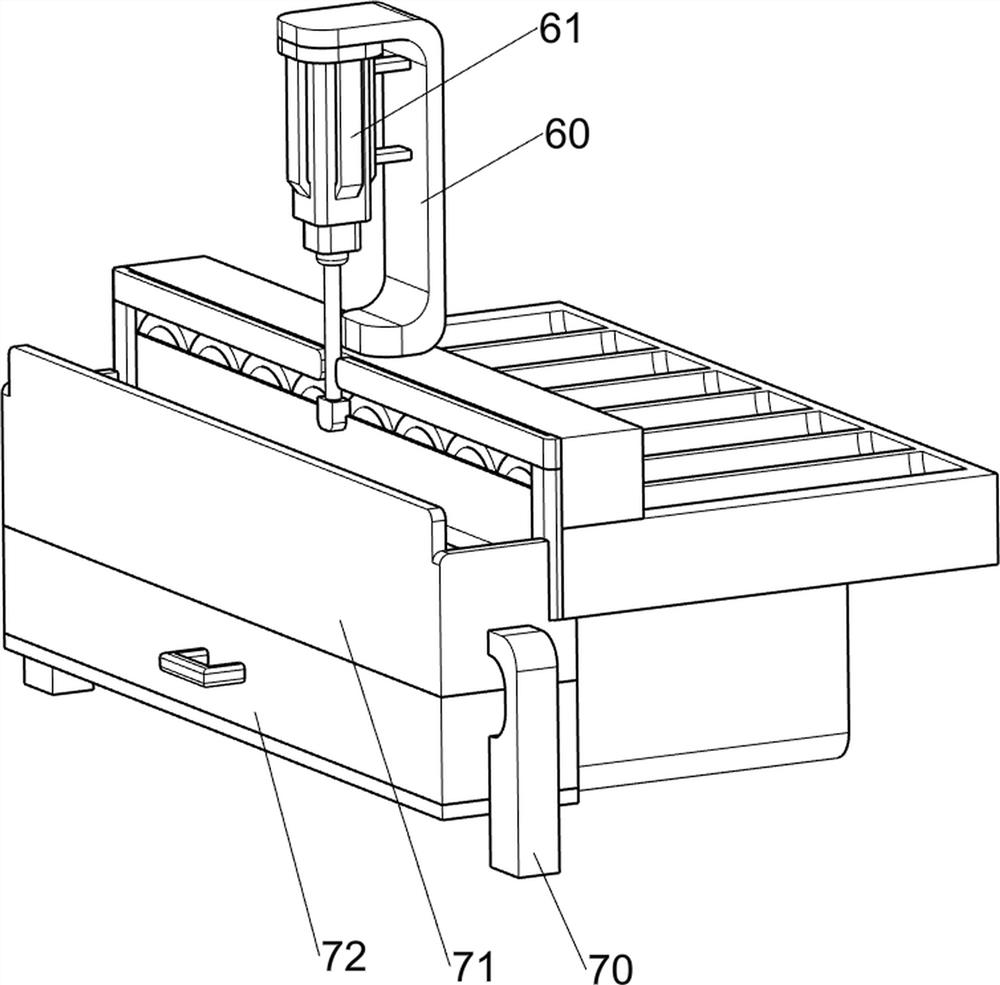

[0029] A slicing device for ham, such as figure 1 , figure 2 and image 3 As shown, it includes a base 1, a first mounting block 2, a first chute 3, a chute 4, a knife 5, a telescoping mechanism 6 and a charging mechanism 7, and the left side of the top of the base 1 is symmetrically provided with a first mounting block 2, The first chute 3 is arranged between the top of the first installation block 2, and the bottom of the first chute 3 is symmetrically provided with a chute 4, and the chute 4 is connected with the first chute 3, and the chute 4 is connected with the first chute. A knife 5 is slidingly provided between the troughs 3, a telescopic mechanism 6 is provided on the first material trough 3, and a charging mechanism 7 is provided on the top of the base 1.

[0030] When people need to use this device, first people place the ham in the first trough 3, then push the ham to the left to a suitable position, so that the ham is located under the knife 5, and then people...

Embodiment 2

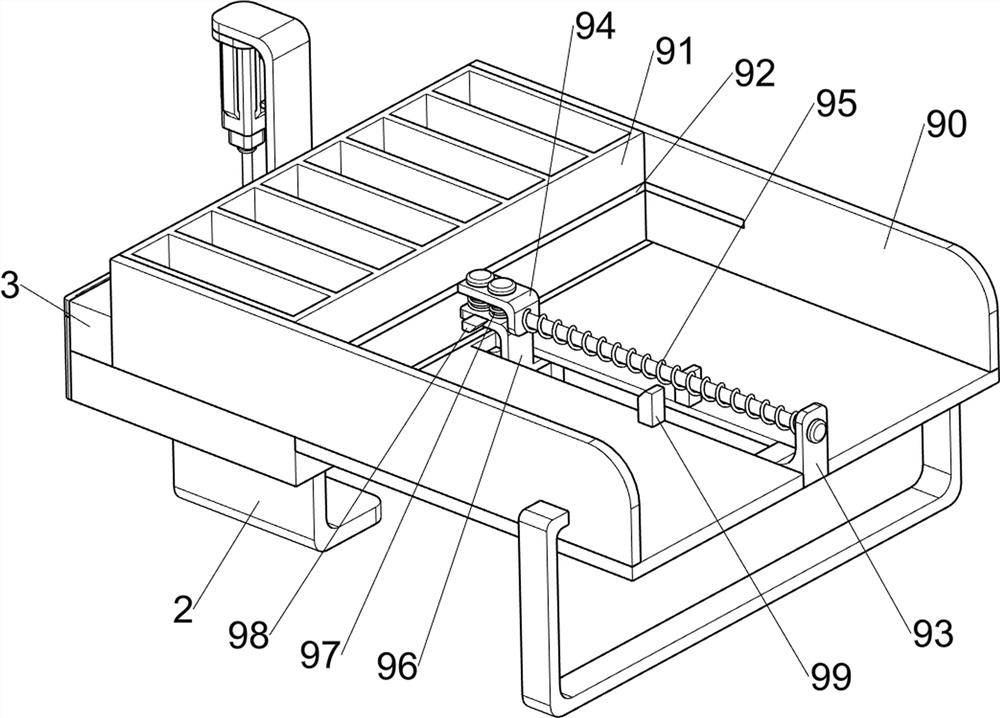

[0035] On the basis of Example 1, such as figure 1 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8As shown, a feed mechanism 8 is also included, and the feed mechanism 8 includes a fourth mounting block 80, a first slide block 81, a fifth mounting block 82, a sixth mounting block 83, a slide bar 84, a first spring 85, a A wedge block 86, the second slide block 87, the seventh mounting block 88, the second cylinder 89 and the first connecting block 810, the top of the base 1 is provided with four fourth mounting blocks 80, and the two fourth mounting blocks on the same side Between 80, the first slide block 81 is provided in a sliding manner, and the fifth installation block 82 is arranged symmetrically front and back on the left side of the first trough 3, and the sixth installation block 83 is arranged on the first slide block 81, and the fifth installation block 82 is provided with slide bar 84 slidingly, and described slide bar 84 is slidably connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com