Production system for preparing PVC floor

A production system and flooring technology, applied in applications, flat products, household appliances, etc., can solve the problems that the durability and firmness of PVC flooring cannot be guaranteed, and the bonding between the substrate layer and the decorative layer is limited.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

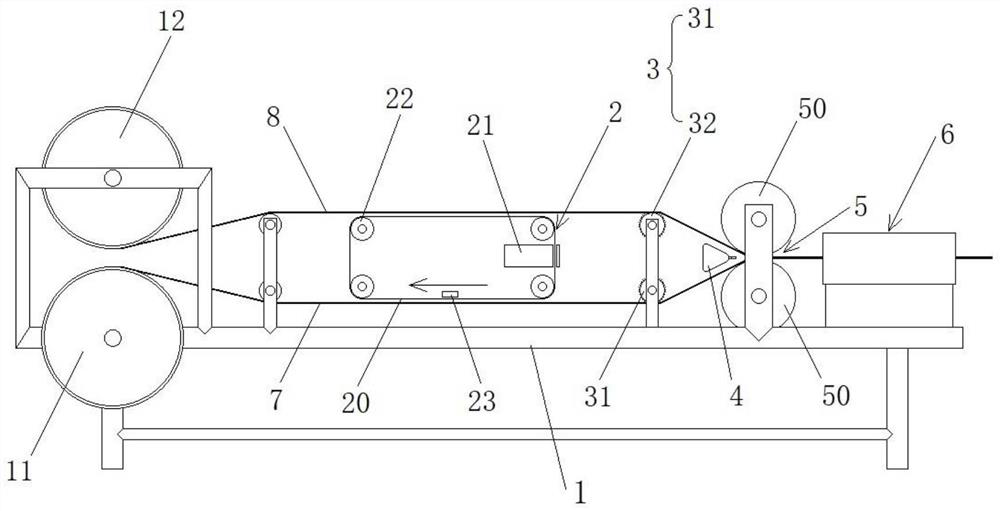

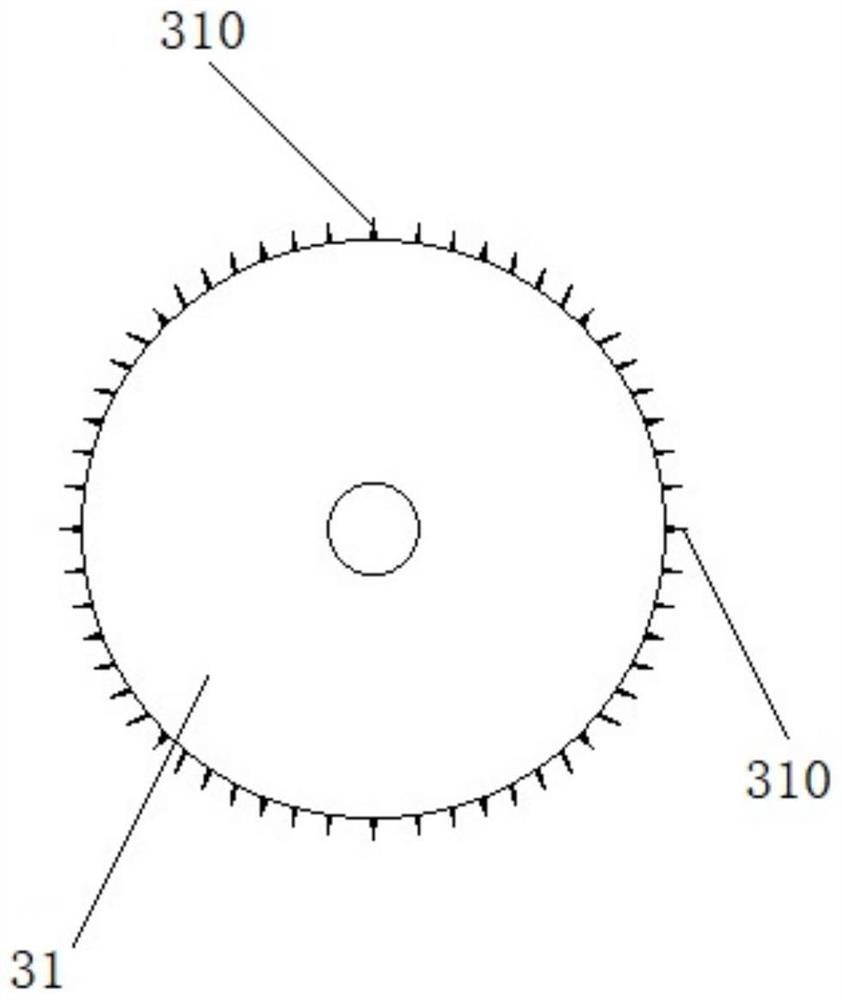

[0030] Specific embodiment 1 of the production system for preparing PVC floor of the present invention, such as figure 1 , figure 2 As shown, the production system for preparing PVC flooring includes a main frame 1, a preheating mechanism 2, a pre-rolling mechanism 3, a gluing mechanism 4, a pressing mechanism 5 and a constant temperature drying mechanism 6, a preheating mechanism 2, a pre-rolling mechanism Mechanism 3, gluing mechanism 4, pressing mechanism 5 and constant temperature drying mechanism 6 are arranged in sequence along the length direction of main frame 1; the feeding end of main frame 1 is provided with a first feeding mechanism 11 and a second feeding me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com