Method for removing algae by ultrasonic wave

An ultrasonic and ultrasonic technology, applied in the field of water treatment technology, can solve the problems of secondary pollution of algal toxins, high ultrasonic power, long release time, etc., and achieve the effect of wide application prospects, simple operation, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

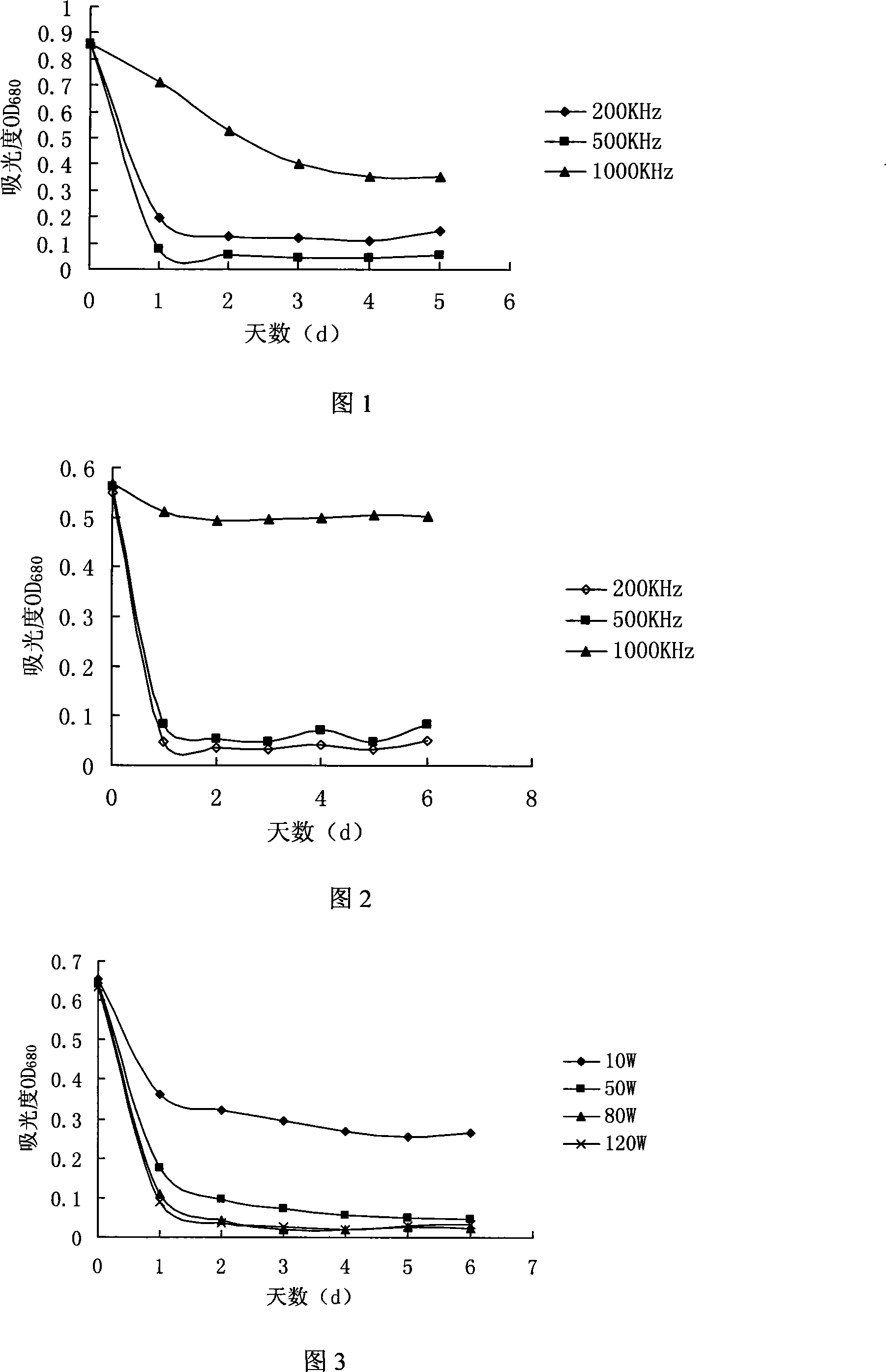

[0016] (1) Take three groups of Microcystis aeruginosa liquids with the same concentration, 100ml each, adjust the output power to 80W, and irradiate them with ultrasound with a frequency of 200KHz, 500KHz and 1000KHz respectively, and the irradiation time is 10min. The algae liquid was placed in a light incubator, and the supernatant was taken every 24 hours to measure the absorbance.

[0017] (2) Take three groups of Microcystis aeruginosa liquids with the same concentration, 100ml each, and irradiate them with ultrasound with a frequency of 200KHz, 500KHz and 1000KHz respectively, the power is all adjusted to 50W, and the irradiation time is 10min. The algae liquid was placed in a light incubator, and the supernatant was taken every 24 hours to measure the absorbance.

[0018] The OD values were measured with a UV spectrophotometer, see accompanying drawings 1 and 2.

[0019] It can be seen from Figure 1 and Figure 2 that the ultrasonic frequency has a great influence on...

Embodiment 2

[0025] (1) Take four groups of Microcystis aeruginosa with the same concentration, each 100ml, irradiate with 200KHz ultrasonic equipment, the power is 10W, 50W, 80W and 120W respectively, and the irradiation time is 10min, and the algae liquid that has been subjected to ultrasonic treatment is left to stand In the light incubator, the supernatant was taken every 24h to measure the absorbance.

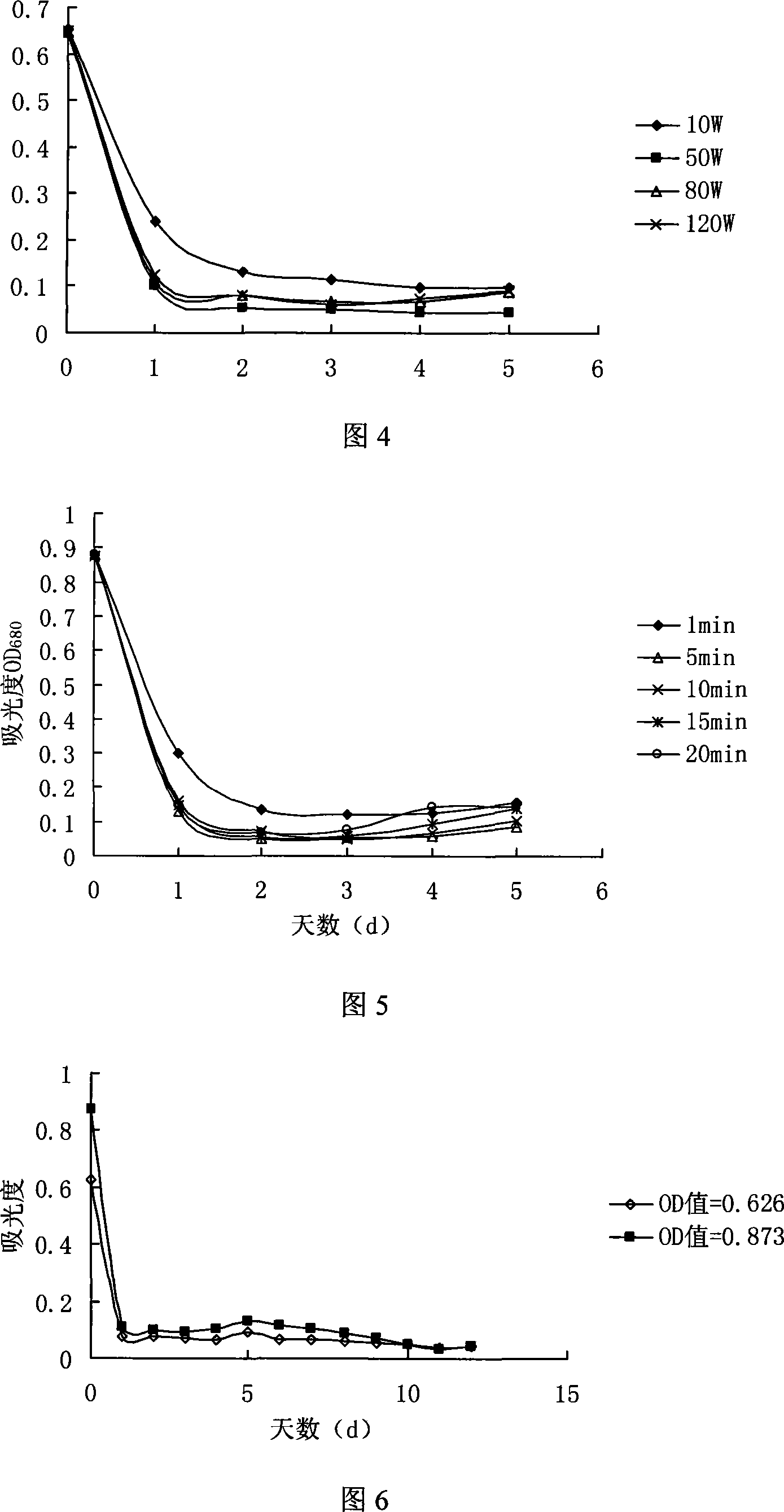

[0026] (2) Take four groups of Microcystis aeruginosa with the same concentration, 100ml each, and irradiate with 500 KHz ultrasonic equipment, the power is 10W, 50W, 80W and 120W respectively, and the irradiation time is 10min. Placed in a light incubator, the supernatant was taken every 24h to measure the absorbance.

[0027] See accompanying drawing 3 and accompanying drawing 4.

[0028] It can be seen from Figure 3 that with the increase of ultrasonic power, the effect of ultrasonic algae removal also increases. When the power is 10W, the removal rate of the first day after ultras...

Embodiment 3

[0031] Take five groups of Microcystis aeruginosa with the same concentration, 100ml each, and irradiate them with ultrasonic equipment with a frequency of 500KHz and a power of 80W. The irradiation time is 1min, 5min, 10min, 15min, and 20min respectively. The solution was kept in a light incubator, and the supernatant was taken every 24 h to measure the absorbance.

[0032] At an ultrasonic power of 80W and a frequency of 500KHz, the changes in the concentration of Microcystis treated with different ultrasonic action times are shown in Figure 5.

[0033] It can be seen from Figure 5 that with the increase of ultrasonic time, the effect of ultrasonic algae removal is also enhanced. When the ultrasonic action time is 1 min, the algae removal rate on the first day after ultrasonic treatment is 66%, while when the ultrasonic action time is 2 min, the algae removal rate is 66%. The algae removal rate reached 85% on the first day after the ultrasonic treatment, but the removal rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com