High-speed single gravure printing machine

A printing machine, high-speed technology, applied in the field of high-speed single gravure printing machine, can solve the problems of insufficient ink scraping of the gravure cylinder, easy tilting of the doctor blade, troublesome operation, etc., to achieve easy replacement and maintenance, easy installation and operation , adjust the effect in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

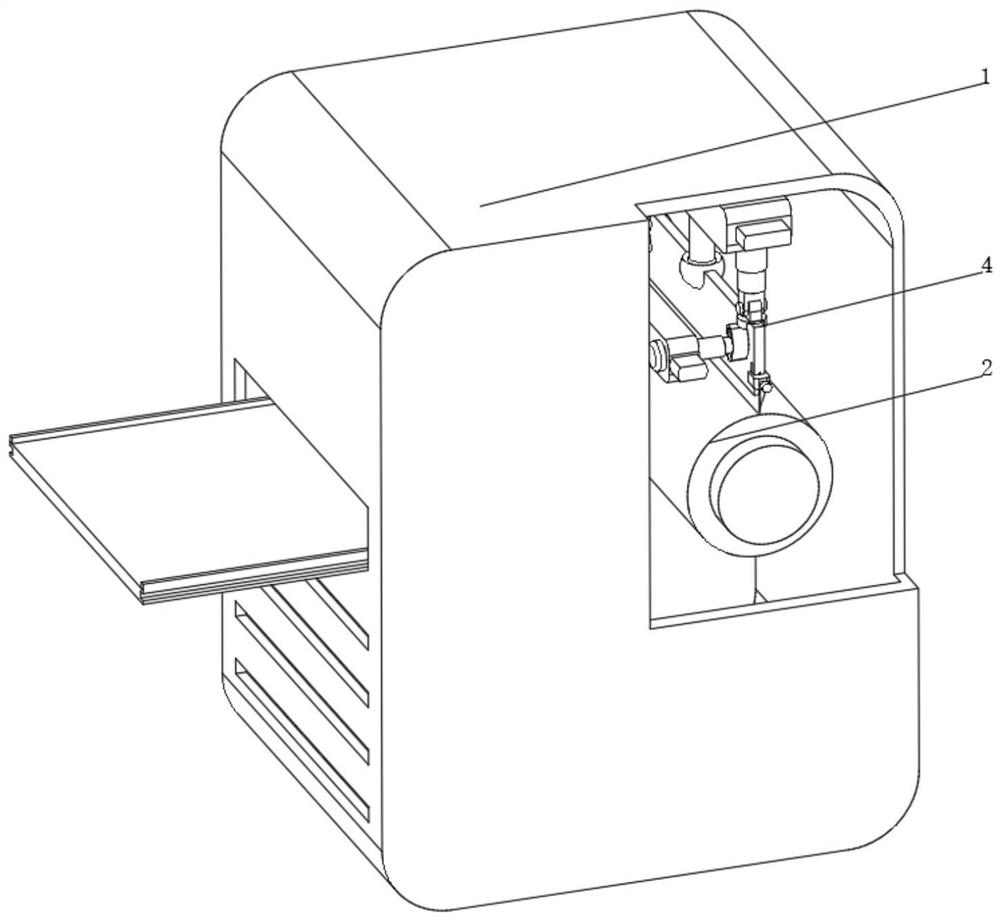

[0035] see Figure 1-2 , the present invention provides a technical solution: a high-speed single gravure printing machine, specifically comprising:

[0036] A printing machine body 1, the printing machine body 1 is provided with a gravure cylinder 2 inside, and both ends of the gravure cylinder 2 are provided with a fixing frame 3, and the fixing frame 3 is fixed on the inner wall of the printing machine body 1;

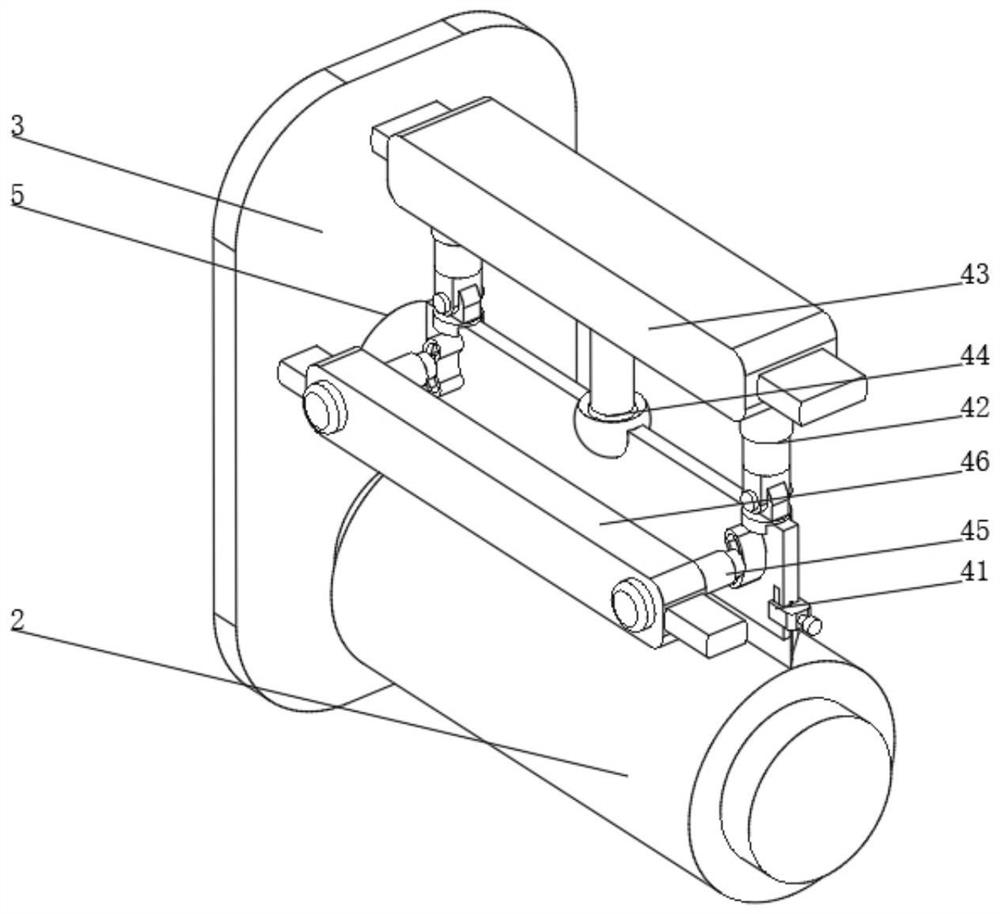

[0037] A scraper device 4, the scraper device 4 is arranged on the part above the gravure cylinder 2 on the fixed frame 3, and the fixed frame 3 and the side of the printing machine body 1 are provided with an installation port 5;

[0038] Scraper device 4 comprises:

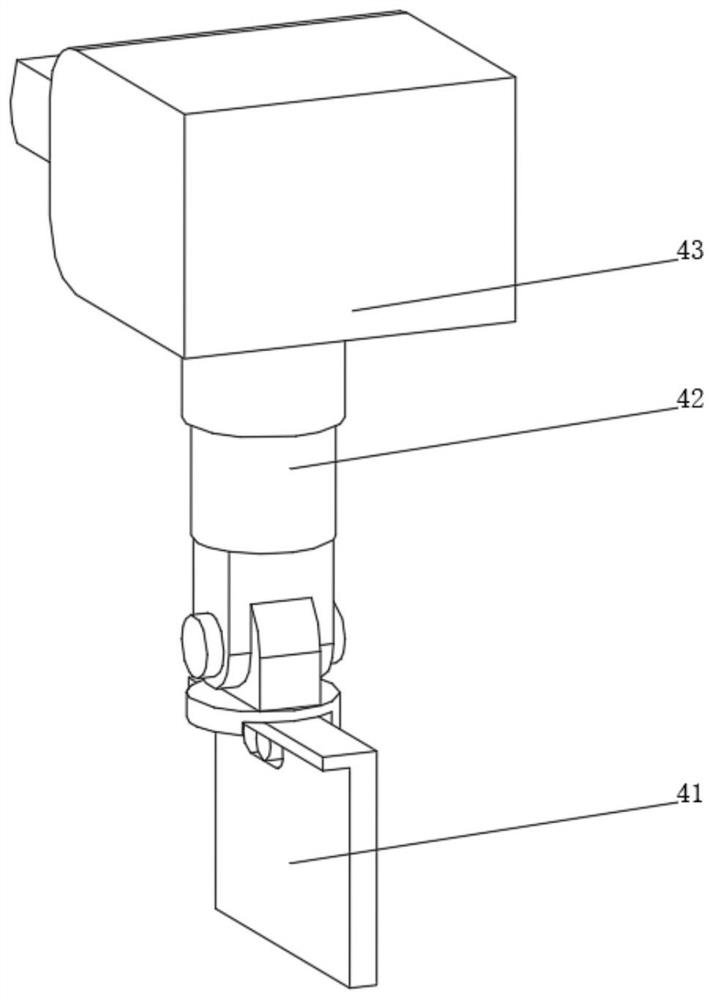

[0039] Fixed knife seat 41, the two ends of the top of the fixed knife seat 41 are connected with a hydraulic telescopic rod 42 through a rotating seat, the top of the hydraulic telescopic rod 42 is fixedly connected with a fixed seat 43, and the center position of the bottom of the fixed seat 43 is ...

Embodiment 2

[0043] see Figure 1-4 On the basis of Embodiment 1, the present invention provides a technical solution: the fixed knife seat 41 includes a base 411, and the bottom of the base 411 is provided with a mounting groove 412, and one side of the mounting groove 412 is slidingly connected to a splint 413, and the inner wall of the mounting groove 412 is slidingly connected There is an ink scraper 414, a chuck 415 is slidably connected to one side of the base 411, a claw 416 is slidably connected to the inner wall of the chuck 415, and a threaded push rod 417 is connected to one side of the claw 416 in rotation, and the threaded push rod 417 is far away from the claw 416. One end passes through the collet 415 and is threadedly connected with the collet 415 , the collet 415 is connected to the base 411 through a limiting groove and can only slide up and down on the side of the base 411 .

[0044] A fixed knife seat 41 is provided, and the scraper 414 can be installed through the inst...

Embodiment 3

[0046] see Figure 1-5 On the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the control device 45 includes a slideway 451, the inner wall of the slideway 451 is slidably connected with a connecting push rod 452, and the connecting push rod 452 is far away from the side of the slideway 451. One end runs through and is slidably connected with a control sleeve 453, the bottom of the inner wall of the control sleeve 453 is fixedly connected with a sub-switch 454, and one end of the connecting push rod 452 located inside the control sleeve 453 is fixedly connected with a female switch 455, and the connecting push rod 452 is connected to the control sleeve. A buffer spring 456 is arranged between the tubes 453, one side of the slideway 451 is fixedly connected to the side of the fixed knife seat 41, and the end of the control sleeve 453 away from the connection push rod 452 is fixedly connected to the side of the control seat 46, and a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com