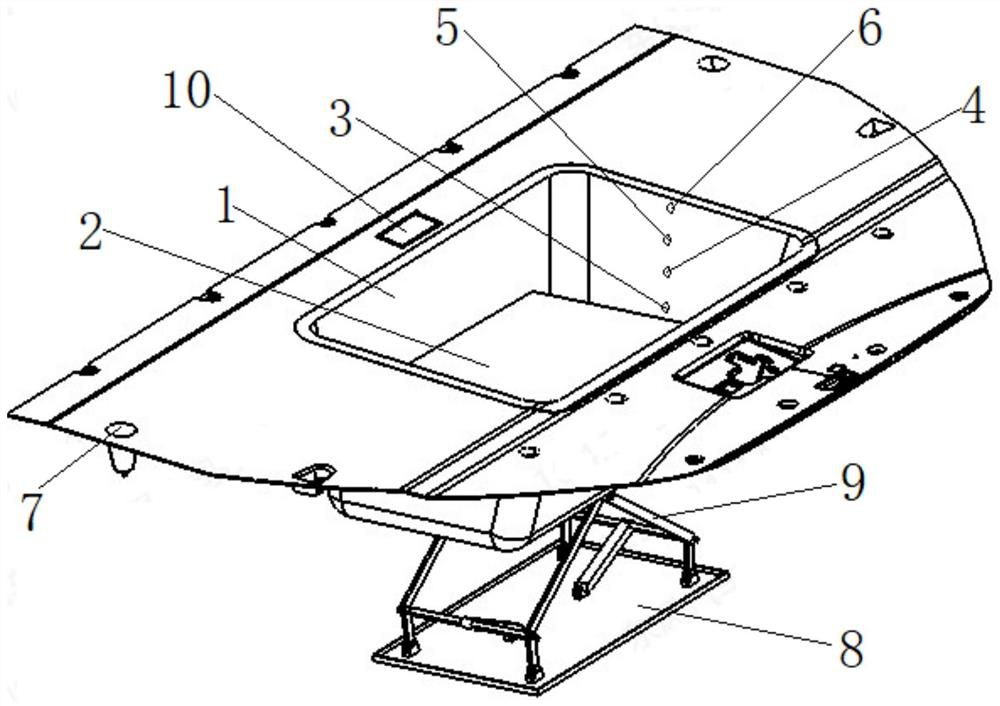

Automatic lifting type off-road vehicle front cabin luggage bracket system and control method

A front cabin, off-road vehicle technology, applied in vehicle parts, transportation and packaging, etc., can solve problems such as hidden safety hazards, inconvenience in taking luggage, and difficulty in taking luggage, so as to improve the user experience and prevent accidental ejection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

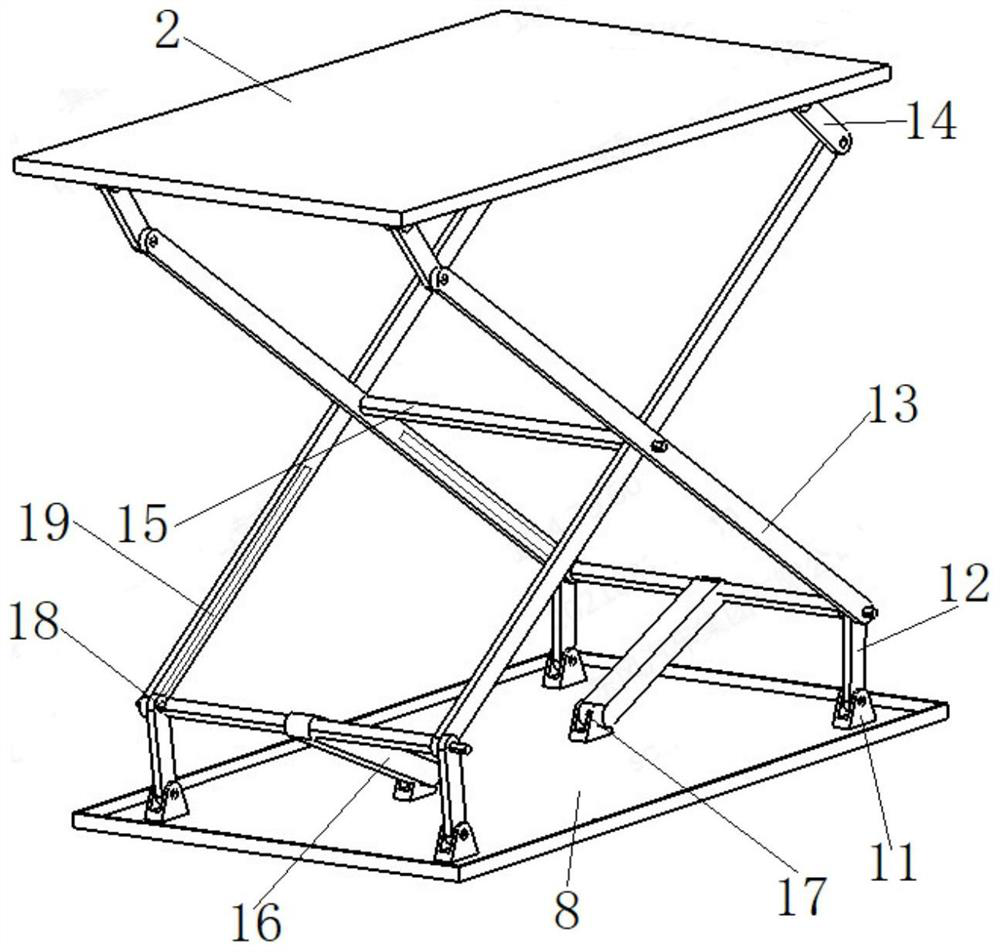

[0047] Embodiment one, such as figure 2 As shown, the lifting mechanism 9 specifically includes: a support 11 , a support rod 12 , a lifting rod 13 , an adjustment rod 14 , an intermediate rod 15 , a driving rod 16 , a driving motor 17 , a slider 18 and a chute 19 .

[0048] Described support 11 is provided with four and is fixed on the upper surface of base 8 in rectangular shape, specifically can be bolted; A lift bar 13 is hinged;

[0049] Wherein, the two lifting rods 13 near the outside of the front nacelle intersect each other and are hinged at their intersection A, and the two lifting rods 13 near the inside of the front nacelle cross each other and are hinged at their intersection B, and the intersection A and An intermediate rod 15 is connected between the intersection points B;

[0050] One end of each lifting rod 13 away from the support rod 12 is hinged with an adjusting rod 14, and the end of the adjusting rod 14 away from the lifting rod 13 is hinged with the ...

Embodiment 2

[0055] Embodiment 2, the principle and technical solution of this embodiment are basically the same as Embodiment 1, the difference is that: the drive rod 16 is a hydraulic telescopic rod, and the two ends of the drive rod 16 are hinged to the lift rod 13, so The forward rotation and reverse rotation of the driving motor 17 respectively drive the hydraulic telescopic rod to shorten and extend, and then drive the two intersecting lifting rods 13 to approach and move away from each other through the hinge movement, so as to realize the rise and fall of the luggage tray 2 .

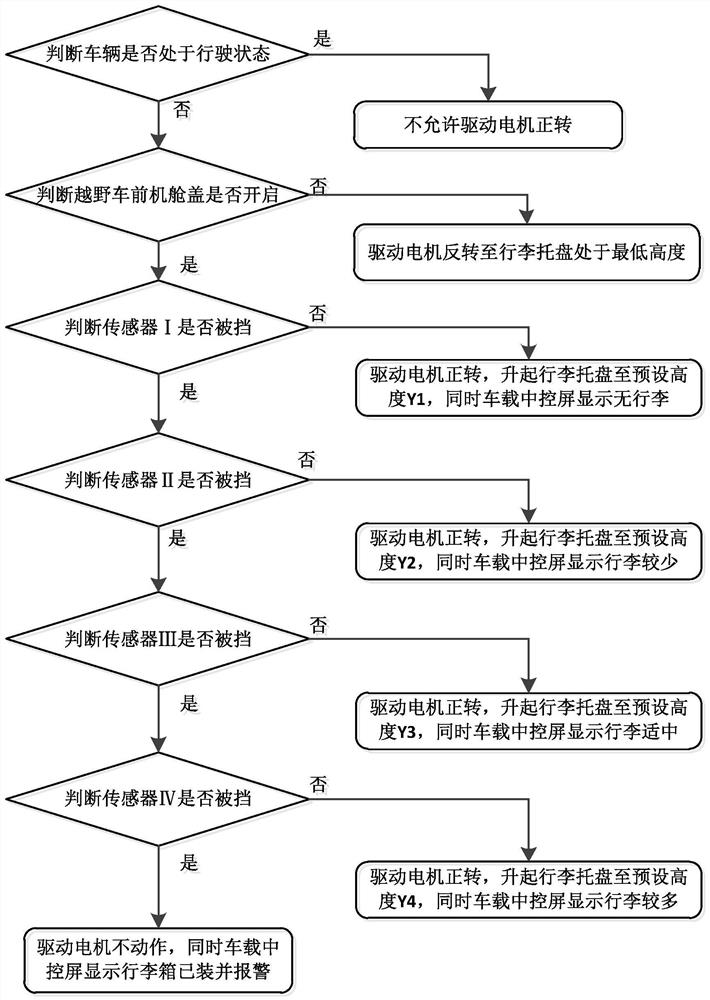

[0056] 3. A control method for the front cabin luggage rack system of an automatic lifting off-road vehicle

[0057] Based on the same inventive concept, the embodiment of the present application also provides a control method for the front cabin luggage rack system of an automatic lifting off-road vehicle, based on the above-mentioned front cabin luggage rack system, such as image 3 As shown, it specifical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com