Conveying roller machine capable of preventing materials from deviating

A technology of conveying rollers and deviations, applied in the field of conveying roller beds, can solve the problems of easy deviation and falling off, troublesome unloading, etc., and achieve the effect of reducing use limitations, reducing troubles, and facilitating unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

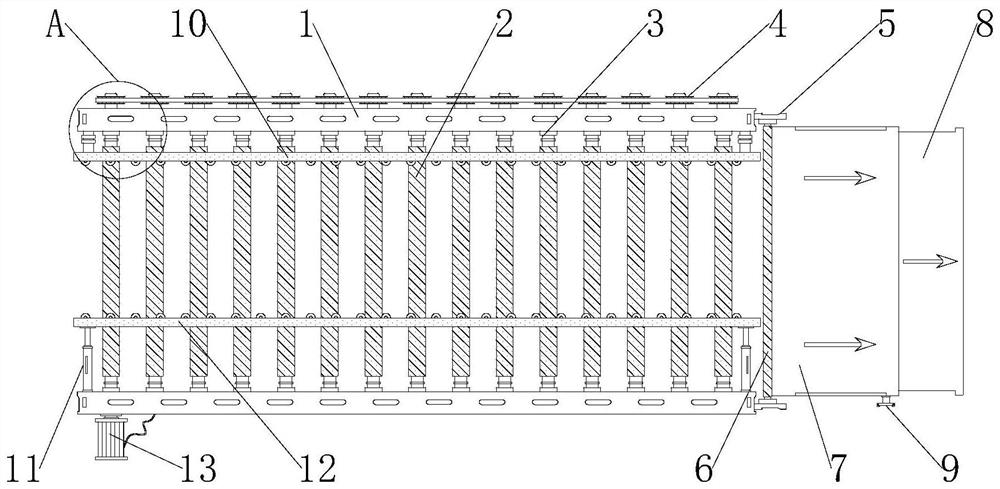

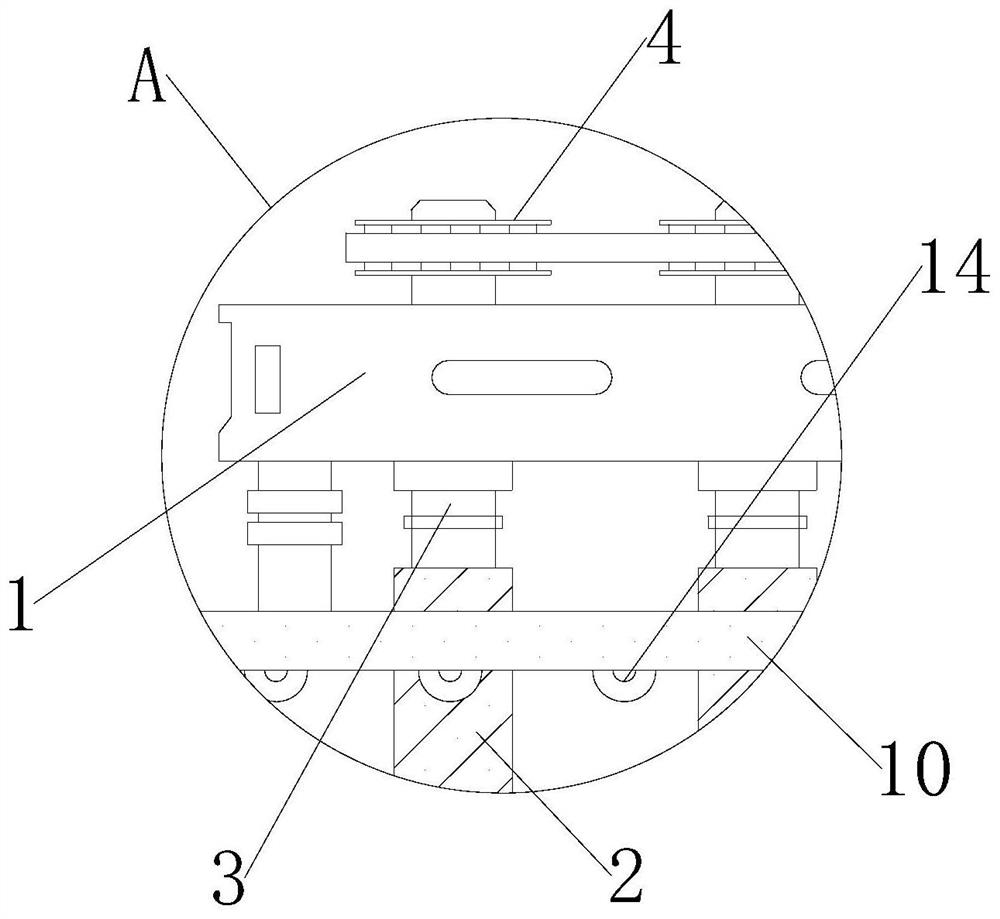

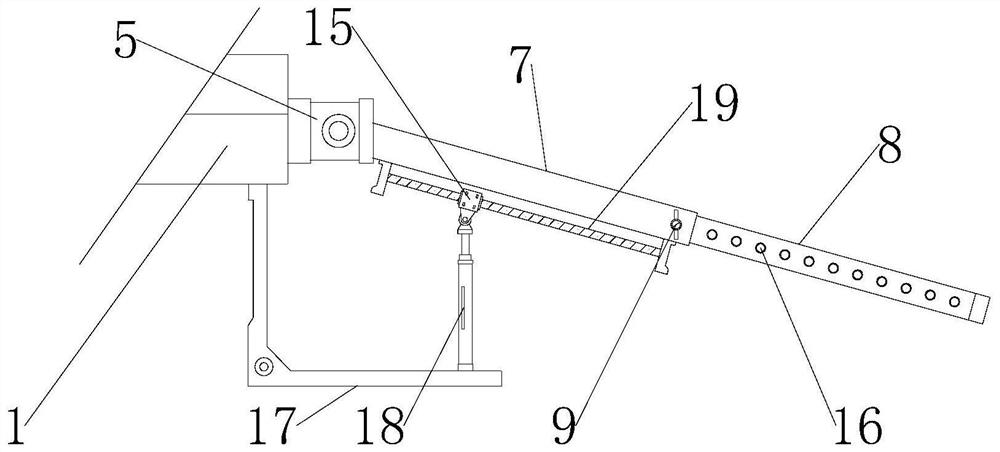

[0018] see Figure 1 to Figure 3 :

[0019] A conveying roller bed for preventing material deviation, including a conveying frame 1:

[0020] The inner side of the conveying frame 1 is provided with several conveying rollers 2, and the front and rear ends of the conveying rollers 2 are fixedly connected with the rotating shaft 3, and the ends of the rotating shaft 3 at the rear end all pass through the back of the conveying frame 1, and the rear ends The periphery of the end of the rotating shaft 3 at the end is fixedly connected with a pulley 4, and several of the pulleys 4 are connected by a belt, and the left side of the front end of the conveyor frame 1 is fixedly connected with a driving motor 13, and the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com