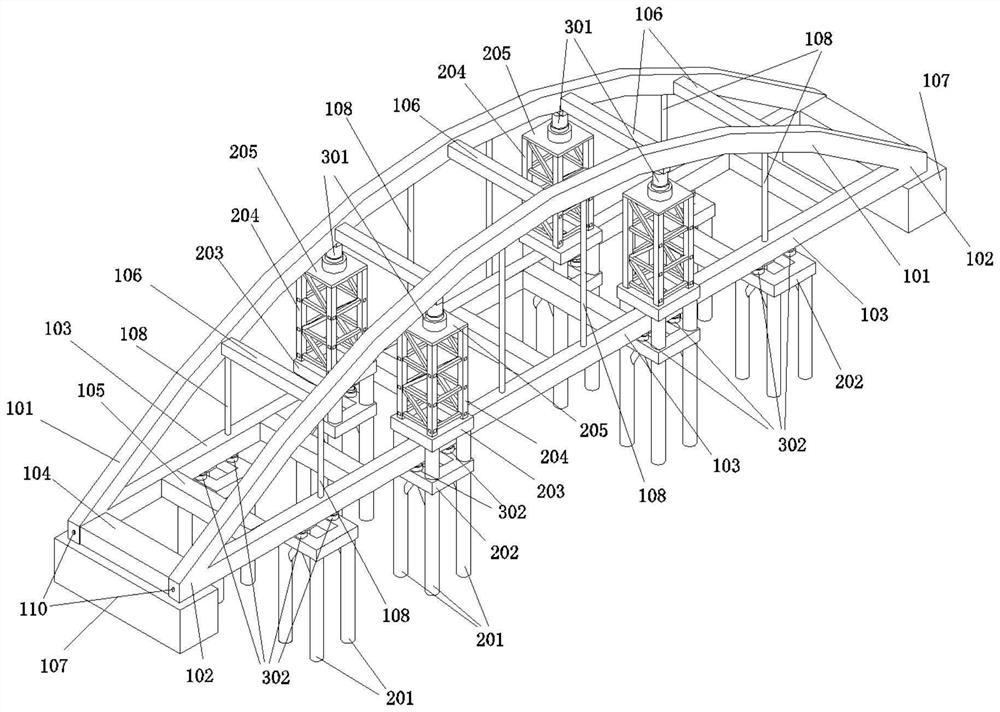

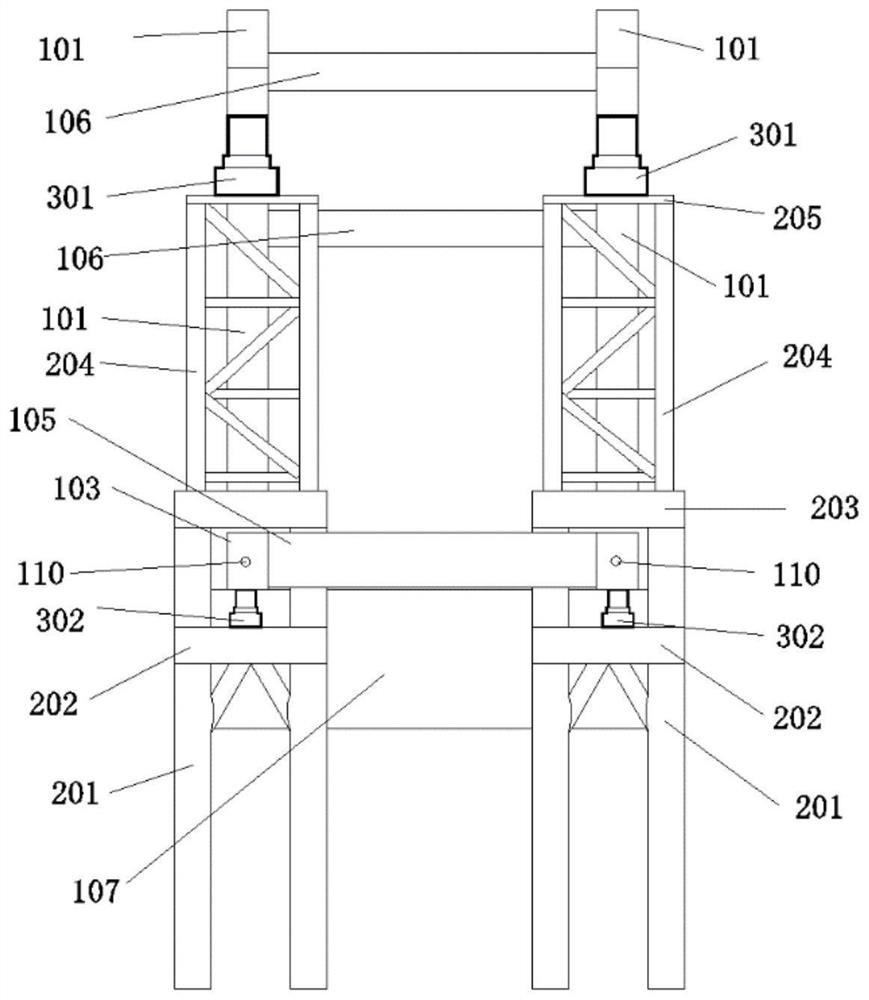

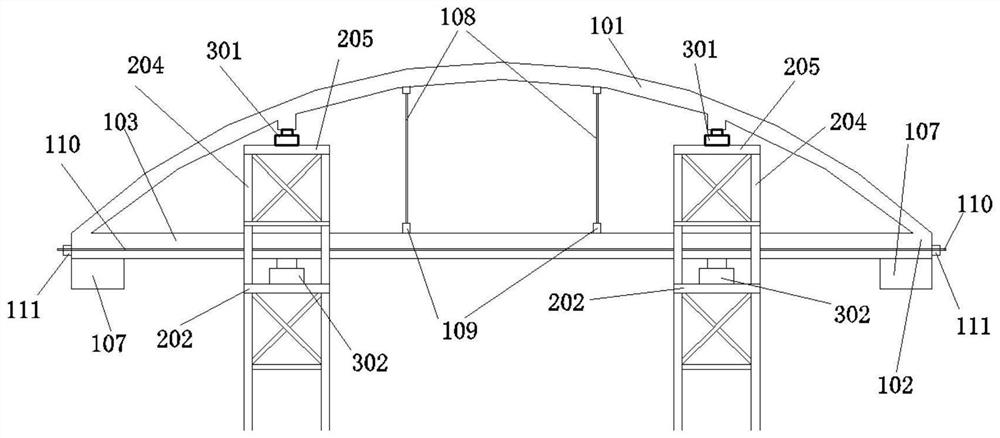

Longitudinal beam and arch rib forming control device of steel arch bridge

A control device and technology for steel arch bridges, which are applied to bridges, arch bridges, bridge materials, etc., can solve the problems of low efficiency, time-consuming and laborious, hidden safety hazards in high-altitude operations, and achieve the effect of improving construction efficiency and accurate and efficient monitoring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0147] Specifically, embodiment 1: take the axis equation of the arch bridge

[0148] Step 11: Simplify the tied arch bridge into a combination of arch rib structure and longitudinal beam structure as shown in the figure. The horizontal stiffness of the arch rib is The horizontal longitudinal stiffness of the stringer is where EI 1 Indicates the bending stiffness of the arch rib, EA 2 Indicates the axial stiffness of the arch rib. The longitudinal beam is suspended on the arch rib through the suspender. It is assumed that after the suspender is tightened, the vertical deformation of the longitudinal beam and the arch rib due to the tension of the tie rod is equal.

[0149] Step 1 and 2: Record the prestress acting on the tie bar as P, according to the horizontal stiffness k of the arch rib 1 and the horizontal stiffness k of the stringer 2 For distribution, the horizontal force distributed to the arch rib The horizontal force distributed on the stringer is The amo...

Embodiment 2

[0153] Embodiment 2: Take the arch axis equation

[0154] Step 21: Simplify the tied arch bridge into a combination of arch rib structure and longitudinal beam structure as shown in the figure. The horizontal stiffness of the arch rib is The horizontal longitudinal stiffness of the stringer is where EI 1 Indicates the bending stiffness of the arch rib, EA 2 Indicates the axial stiffness of the arch rib. The longitudinal beam is suspended on the arch rib through the suspender. It is assumed that after the suspender is tightened, the vertical deformation of the longitudinal beam and the arch rib due to the tension of the tie rod is equal.

[0155] Step 22: Record the prestress acting on the tie bar as P, according to the horizontal stiffness k of the arch rib 1 and the horizontal stiffness k of the stringer 2 For distribution, the horizontal force distributed to the arch rib The horizontal force distributed on the stringer is The horizontal shrinkage of the stringer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com