A filling stope closure device and system with monitoring function

A closed device and closed system technology, applied in measuring devices, fillers, safety devices, etc., can solve the problems of large number, narrow measuring point range and high cost, and achieve the effect of realizing data, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

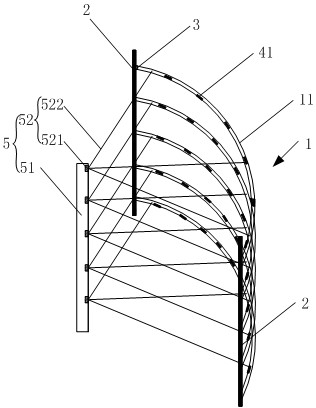

Embodiment 1

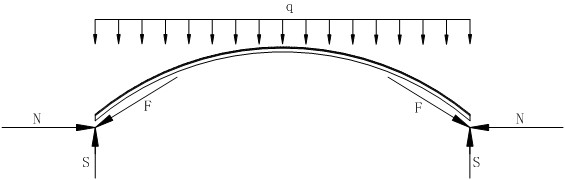

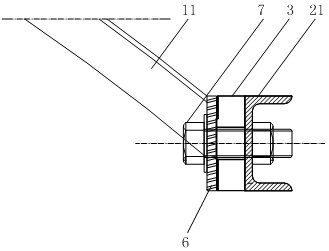

[0052] In this embodiment one, if image 3 As shown, the end of the arc beam 11 is provided with a connecting plate 6, and the fixed frame 2 includes a first strip 21 for connecting with the roadway side wall rock; the first strip 21 and the connecting plate 6 are connected by a first The member 7 is equipped with a pressure monitor 3, and the pressure direction of the pressure monitor 3 is perpendicular to the length direction of the first strip 21.

[0053] During the monitoring process, the first connector 7 can balance the shear force of the curved beam 11, and the positive pressure of the curved beam 11 directly acts on the pressure monitor 3, that is, the pressure surface of the pressure monitor 3 is perpendicular to the curved beam 11 positive pressure. The above-mentioned pressure monitor 3 has a simple installation method and can effectively monitor the positive pressure on the first strip 21 with accurate monitoring data.

[0054] Wherein, the first strip 21 can be...

Embodiment 2

[0059] In the second embodiment, if Figure 4 As shown, the end of the arc-shaped beam 11 is provided with a connecting plate 6, and the fixed frame 2 includes a second strip 22 for connecting with the roadway side wall rock and a plurality of short-circuits corresponding to the plurality of arc-shaped beams 11 one-to-one. 23; the bending radian of the shorting piece 23 is consistent with the arc beam 11; one end of the shorting piece 23 is connected to the second strip 22, and the other end of the shorting piece 23 is connected to the connecting plate 6 through the second connecting piece 8 A pressure monitor 3 is installed, and the pressure receiving direction of the pressure monitor 3 is parallel to the tangential direction of the end of the arc beam 11 .

[0060] During the monitoring process, since the bending radian of the short-connector 23 is consistent with the arc-shaped beam 11, the axial force of the arc-shaped beam 11 directly acts on the pressure monitor 3 betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com