Method for determining epoxy chloropropane in water

A technology for the determination of epichlorohydrin and its method, which is applied in the field of chemical analysis, can solve the problems of cumbersome operation and poor reproducibility, and achieve the effects of high sensitivity, high extraction efficiency and good work requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

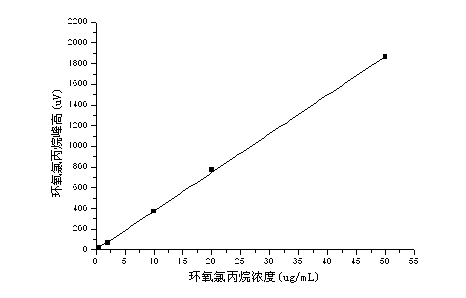

Image

Examples

example 1

[0029] Determination of Epichlorohydrin Content in Epoxy Resin Plant Wastewater

[0030] Water samples were collected in 1000 mL brown reagent bottles at the outlet of an epoxy resin factory workshop, and three samples were collected in parallel. Take 100mL water sample and place it in a 250mL separatory funnel, adjust the pH value to 6.0-7.0, add 5g of magnesium chloride and shake to dissolve. Add 5.00mL of dichloromethane and shake for 10min, let stand to separate and collect the lower layer of dichloromethane solution; then continue to add 3.00mL of dichloromethane to the separated waste water, shake for 10min, let stand to separate and combine Collect the dichloromethane solution in the lower layer: continue to add 2.00mL of dichloromethane to the separated wastewater, shake for 10 minutes, let stand to separate layers, combine and collect the dichloromethane solution in the lower layer, shake well, and wait for capillary chromatography analysis.

[0031] (1) Test instrum...

example 2

[0051] Determination of Epichlorohydrin Content in Epoxy Diluent Workshop Wastewater of Chemical Plant

[0052] Collect water samples in 1000 mL brown reagent bottles at the drain, and collect 3 samples in parallel. Take 100mL water sample and place it in a 250mL separatory funnel, adjust the pH value to 6.0-7.0, add 5g of magnesium chloride and shake to dissolve. Add 5.00mL of dichloromethane and shake for 10min, let stand to separate and collect the lower layer of dichloromethane solution; then continue to add 3.00mL of dichloromethane to the separated waste water, shake for 10min, let stand to separate and combine Collect the dichloromethane solution in the lower layer: continue to add 2.00mL of dichloromethane to the separated wastewater, shake for 10 minutes, let stand to separate layers, combine and collect the dichloromethane solution in the lower layer, shake well, and wait for capillary chromatography analysis.

[0053] (1) Test instrument: Zhejiang Wenling Fuli Anal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com